Fireproofing heat-insulating door with porous cement structure and manufacturing method thereof

A manufacturing method and technology of insulating doors, applied to fire doors, chemical instruments and methods, door leaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

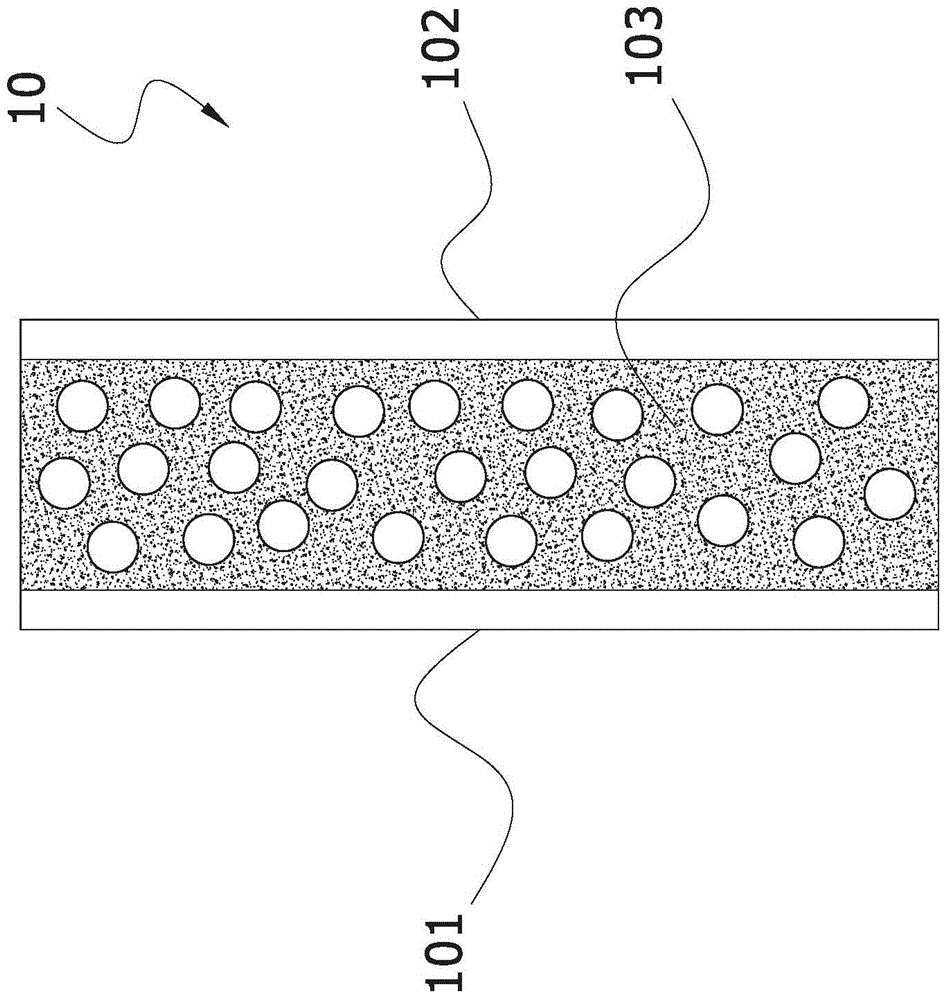

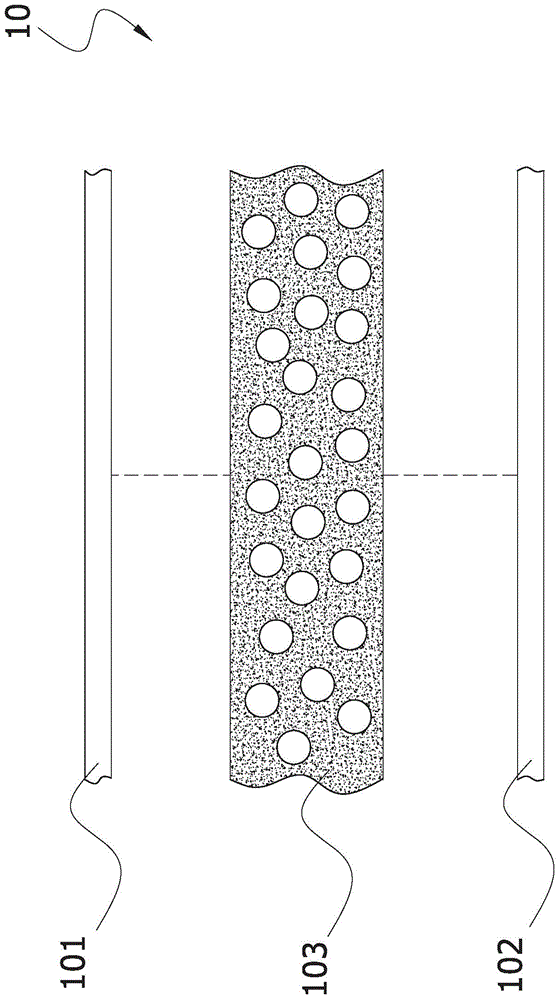

[0059] see figure 1 , shown in the figure is a schematic cross-sectional view of the present invention, as shown in the figure, a fireproof and insulating door 10 with a porous cement structure, which is mainly composed of a first slab 101, a second slab 102 and a foamed cement layer 103; wherein, the first layer 101 and the second layer 102 can be, for example, wooden, metal, or plastic boards, and the foamed cement layer 103 is made of foamed cement slurry with fireproof and heat-insulating materials Formed upon curing; see next figure 2 , shown in the figure is a schematic diagram of the composition of the present invention, one side of the foamed cement layer 103 shown in the figure is assembled with the first layer 101, and the other side is assembled with the second layer 102, wherein, The first plate layer 101 and the second plate layer 102 can be locked with the foamed cement layer 103 by one screw, or, when the foamed cement layer 103 has not yet solidified, becaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com