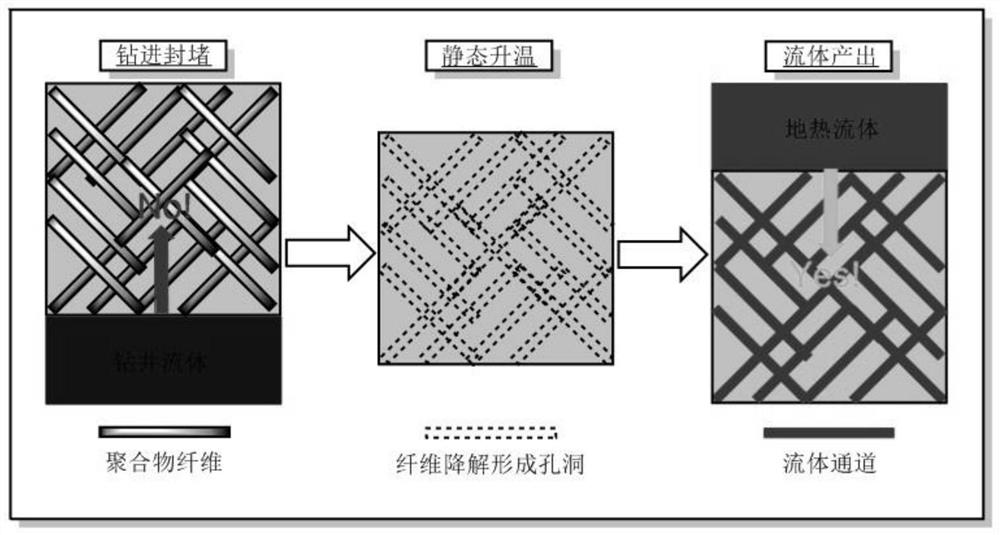

Temporary plugging type high-water-permeability porous cement-based material suitable for medium-low temperature geothermal wells and preparation method thereof

A technology of cement-based materials and geothermal wells, applied in chemical instruments and methods, applications, household appliances, etc., can solve problems such as easy deposition of cement blocks near the drill bit, damage to reservoir permeability, and high cement density, so as to reduce the density , Optimize rheology, reduce density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned temporary plugging type highly permeable porous cement-based material suitable for medium and low temperature geothermal wells includes the following steps:

[0039] Step 1: Use a cement slurry mixer to dry and mix the raw materials at a low speed, wherein the raw materials include oil well cement, floating beads, and PVA fibers;

[0040] Step 2: Continue to open the cement paste mixer equipped with uniformly mixed raw materials, add tap water to it, and add according to the water-cement ratio W / C of 0.5. After adding, continue to keep the mixer at low speed, and turn on the stopwatch to start timing;

[0041] Step 3: After the raw materials and water are mixed at low speed, stop, and high speed by the cement slurry mixer, the slurry material of the temporary plugging type highly permeable porous cement-based material is prepared;

[0042] Step 4: After the slurry is prepared, inject the slurry into the cube triple test mol...

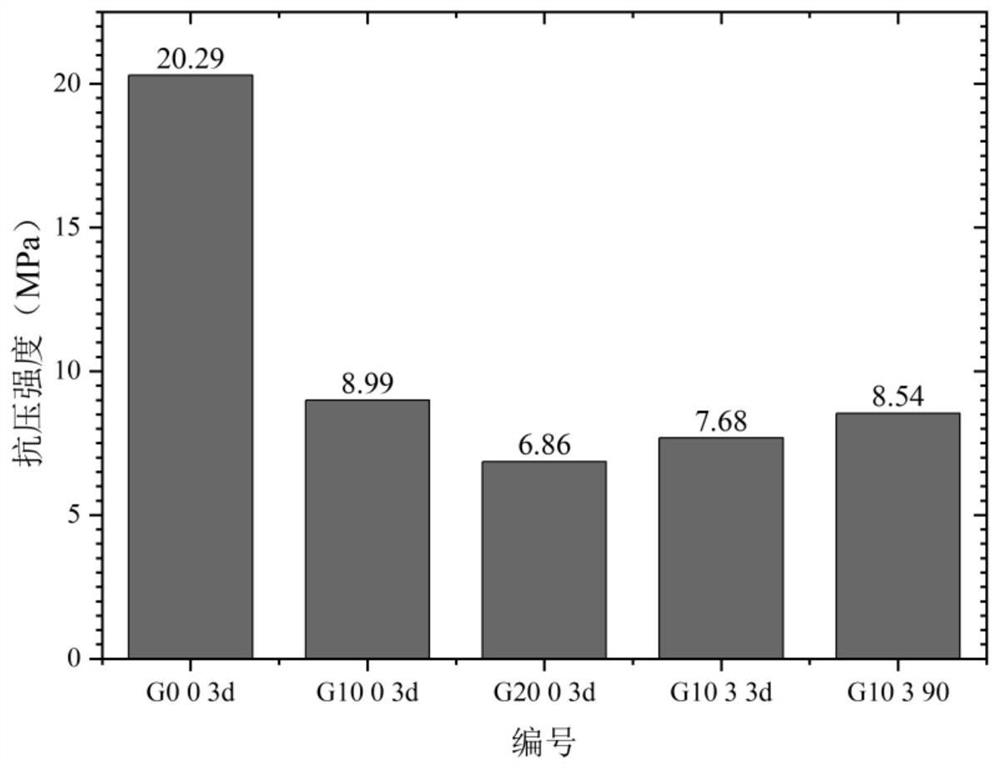

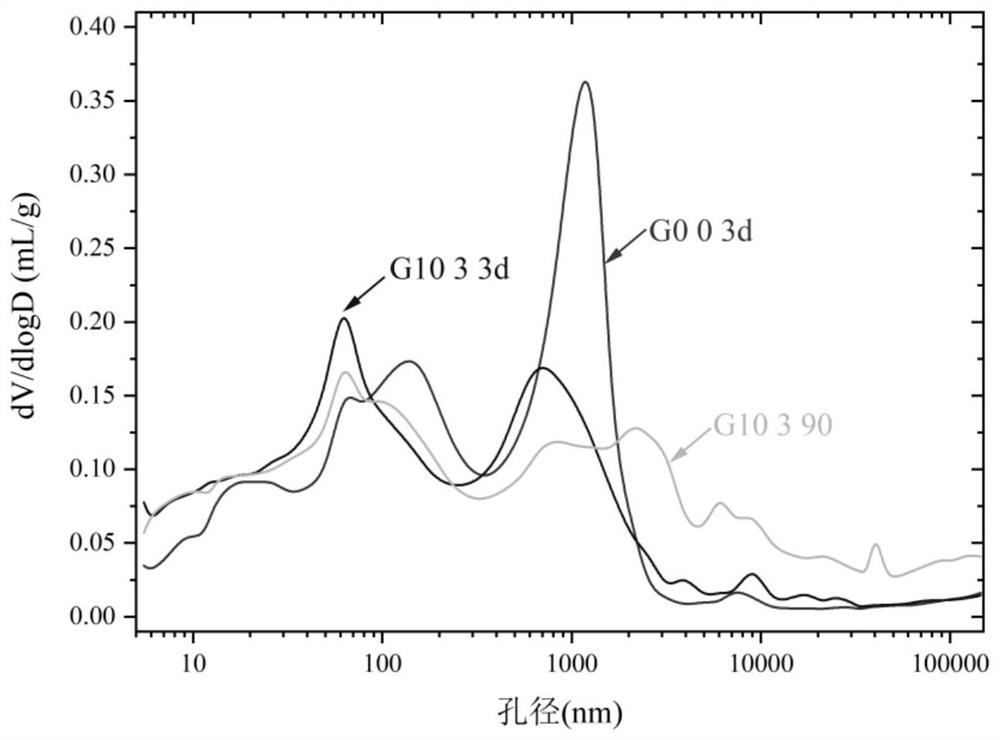

Embodiment 1

[0045]Temporary plugging type highly permeable porous cement-based material suitable for medium and low temperature geothermal wells, including the following raw material formula in mass percentage: oil well cement 70%, fly ash floating beads 20%, PVA fiber / particle 10%, water-cement ratio W / C is 0.5.

[0046] Based on the above-mentioned temporary plugging type highly permeable porous cement-based material, a preparation method of a temporary plugging type highly permeable porous cement-based material suitable for medium and low temperature geothermal wells is proposed, including the following steps:

[0047] Step 1: Use a cement paste mixer to dry and mix all raw materials at a low speed. The raw materials include oil well cement, floating beads, and PVA fibers. The mixing time is not less than 3 minutes to ensure that all raw materials are mixed evenly under dry conditions;

[0048] Step 2: Continue to open the cement paste mixer equipped with uniformly mixed raw materials...

Embodiment 2

[0053] Temporary plugging type highly permeable porous cement-based material suitable for medium and low temperature geothermal wells, including the following raw material formula in mass percentage: oil well cement 80%, fly ash floating beads 0-20%, PVA fiber / particle 0-10%, water The gray ratio W / C is 0.5.

[0054] The preparation method of the temporary plugging type porous cement suitable for medium and low temperature geothermal wells comprises the following steps:

[0055] Step 1: Use a cement paste mixer to dry and mix all raw materials at a low speed. The raw materials include oil well cement, floating beads, and PVA fibers. The mixing time is not less than 3 minutes to ensure that all raw materials are mixed evenly under dry conditions;

[0056] Step 2: Continue to open the cement paste mixer equipped with uniformly mixed raw materials, add ordinary tap water to it, and add according to the water-cement ratio W / C of 0.5, continue to keep the mixer at low speed, and tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com