Semi-hydrated phosphogypsum filling material and preparation method thereof

A technology of hemihydrate phosphogypsum and filling material, applied in the field of mine filling material, can solve the problems of slow setting time, low early strength, low utilization rate of phosphogypsum, etc., so as to improve fluidity, stimulate gelling performance, and reduce stockpiling. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of the above-mentioned phosphogypsum hemihydrate filling material, comprising the following steps:

[0025] After the hemihydrate phosphogypsum is dried, it is weighed with quicklime, dihydrate phosphogypsum, coagulation accelerator or retarder according to the proportion, mixed evenly, and water is added to prepare hemihydrate phosphogypsum filling slurry.

[0026] Preferably, in the preparation method of the above-mentioned hemihydrate phosphogypsum-based paste filling material, the solid content of the hemihydrate phosphogypsum filling slurry is 65-80%, and the slump of the slurry is 20-25cm.

[0027] In the present invention, the industrial by-product hemihydrate phosphogypsum after drying and dehydration is used as the cementitious material, which is convenient for storage and transportation of the cementitious material, and quicklime is added as a pH regulator to solidify acidic impurities such as P and F in ...

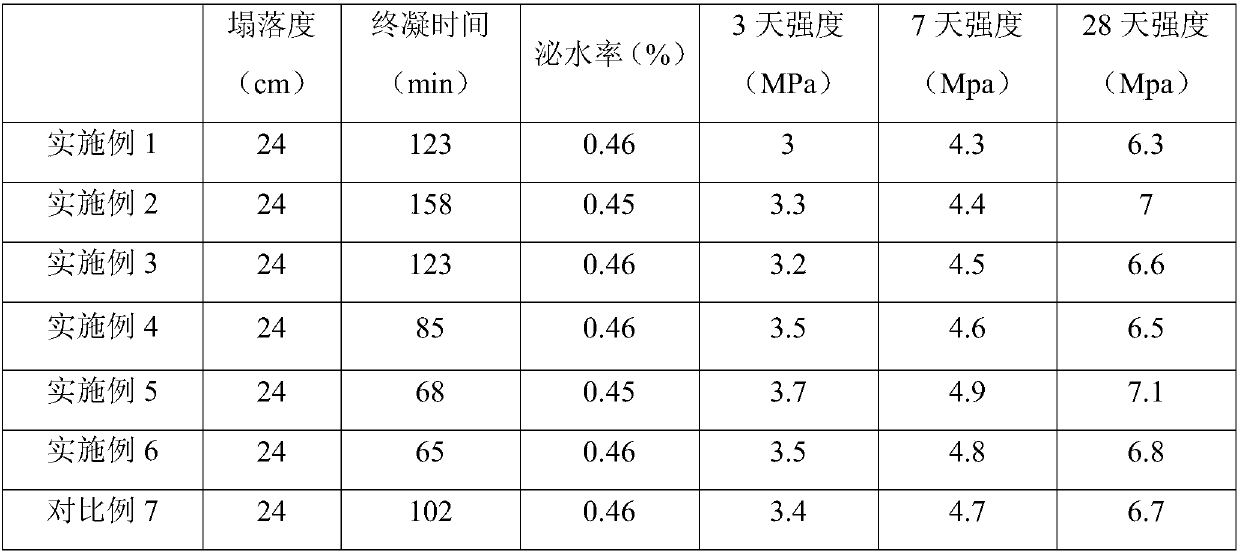

Embodiment 1

[0030] Embodiment 1 prepares hemihydrate phosphogypsum filling material of the present invention

[0031] Add 49 parts of hemihydrate phosphogypsum with a crystal water content of 6%, 50 parts of dihydrate phosphogypsum, 1 part of quicklime, 0.001 part of retarder (sodium citrate), and add water to prepare a slurry with a solid content of 75%. , that is.

Embodiment 2

[0032] Embodiment 2 prepares hemihydrate phosphogypsum filling material of the present invention

[0033] Prepare 80 parts of hemihydrate phosphogypsum with a crystal water content of 6%, 30 parts of dihydrate phosphogypsum, 5 parts of quicklime, 0.003 part of retarder (sodium succinate), and add water to prepare a slurry with a solid content of 75%. , that is.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com