High-strength steel slag concrete for building artificial fish reef

A high-strength steel and artificial fish reef technology, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the limitations of artificial fish reef structure size and structure shape, poor surface hardness and corrosion resistance, concrete Require high-level issues to achieve the effect of improving marine biodiversity, rough surface, and strong water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

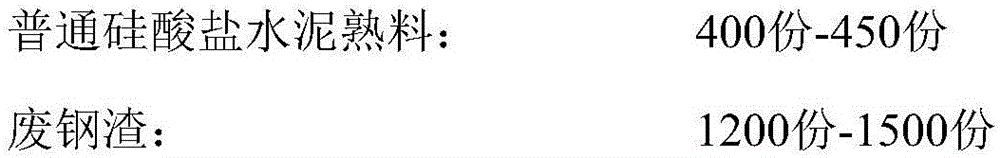

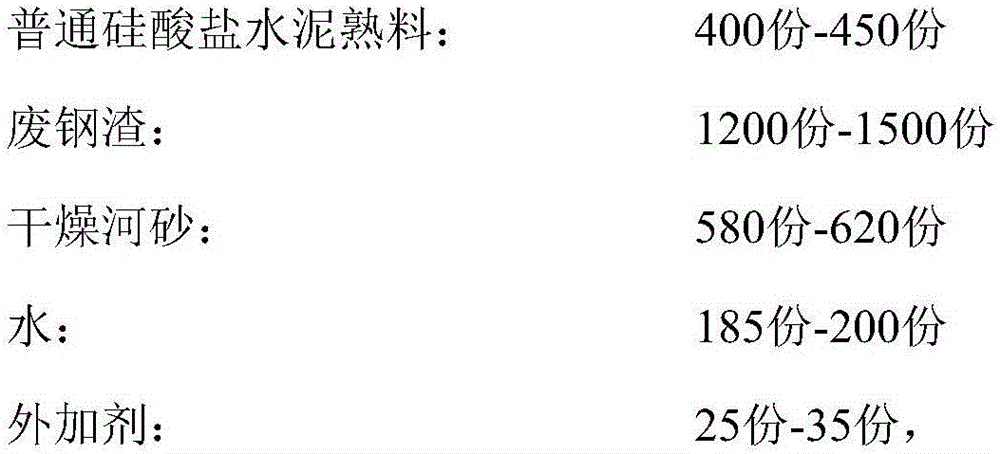

[0030] A high-strength steel slag concrete used for building artificial fish reefs, comprising the following components in parts by mass:

[0031]

[0032]

[0033] Wherein, the density of the ordinary Portland cement clinker is 3.02g / cm 3 ;The initial setting time of cement is 212min>45min, the final setting time is 280min2 , dicalcium silicate 2CaO·SiO 2 , Tricalcium aluminate 3CaO·Al 2 o 3 and tetracalcium aluminoferrite 4CaO·Al 2 o 3 · Fe 2 o 3 ;

[0034] Wherein, the crushing value of the steel scrap slag is 12.8%3 , close packing density at 1.80g / cm 3 , the average water absorption rate is 3.3%, and the basicity of steel slag is calculated by M=CaO / (SiO 2 +P 2 o 5 )%, with an alkalinity of 2.30%, which belongs to medium active slag, and the main mineral composition is olivine 2FeO·SiO 2 , dicalcium silicate 2CaO·SiO 2 , tricalcium silicate 3CaO·SiO 2 , dicalcium ferrite 2CaO·Fe 2 o 3 , fluorapatite 9CaO·3P 2 o 5·CaF 2 and free calcium oxide fCaO; ...

example 2

[0040] A high-strength steel slag concrete used for building artificial fish reefs, comprising the following components in parts by mass:

[0041]

[0042] Wherein, the density of the ordinary Portland cement clinker is >3.02g / cm 3 ; The initial setting time of cement is 186min>45min, the final setting time is 310min2 , dicalcium silicate 2CaO·SiO 2 , Tricalcium aluminate 3CaO·Al 2 o 3 and tetracalcium aluminoferrite 4CaO·Al 2 o 3 · Fe 2 o 3 ;

[0043] Wherein, the crushing value of the steel scrap slag is 8.3%3 , close packing density at 1.83g / cm 3 , the average water absorption rate is 3.5%, and the basicity of steel slag is calculated as M=CaO / (SiO 2 +P 2 o 5 )%, with an alkalinity of 2.33%, which belongs to medium active slag, and the main mineral composition is olivine 2FeO·SiO 2 , dicalcium silicate 2CaO·SiO 2 , tricalcium silicate 3CaO·SiO 2 , dicalcium ferrite 2CaO·Fe2O 3 , fluorapatite 9CaO·3P 2 o 5 ·CaF 2 and free calcium oxide fCaO;

[0044] Whe...

example 3

[0049] A high-strength steel slag concrete used for building artificial fish reefs, comprising the following components in parts by mass:

[0050]

[0051] Wherein, the density of the ordinary Portland cement clinker is >3.00g / cm 3 ;The initial setting time of cement is 121min>45min, the final setting time is 237min2 , dicalcium silicate 2CaO·SiO 2 , Tricalcium aluminate 3CaO·Al 2 o 3 and tetracalcium aluminoferrite 4CaO·Al 2 o 3 · Fe 2 o 3 ;

[0052] Wherein, the crushing value of the steel scrap slag is 13.23 , close packing density is 1.85g / cm 3 , the average water absorption rate is 3.6%, and the basicity of steel slag is calculated as M=CaO / (SiO 2 +P 2 o 5 )%, the alkalinity is between 2.35%, which belongs to the medium active slag, and the main mineral composition is olivine 2FeO·SiO 2 , dicalcium silicate 2CaO·SiO 2 , tricalcium silicate 3CaO·SiO 2 , dicalcium ferrite 2CaO·Fe 2 o 3 , fluorapatite 9CaO·3P 2 o 5 ·CaF 2 and free calcium oxide fCaO;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com