Mineral powder prepared by neutralizing slag from industrial waste and its preparation method

A technology of industrial waste slag and mineral powder, which is applied in the field of resource-based new technology materials, can solve problems such as ineffective treatment, landfilling, and environmental pollution, so as to save natural mineral resources and energy, reduce energy conservation, emission reduction, and carbon emissions , the effect of changing the physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

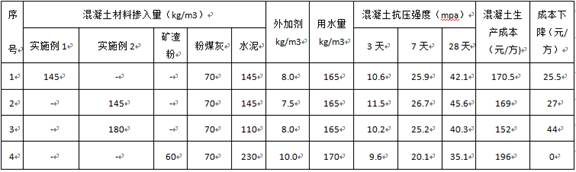

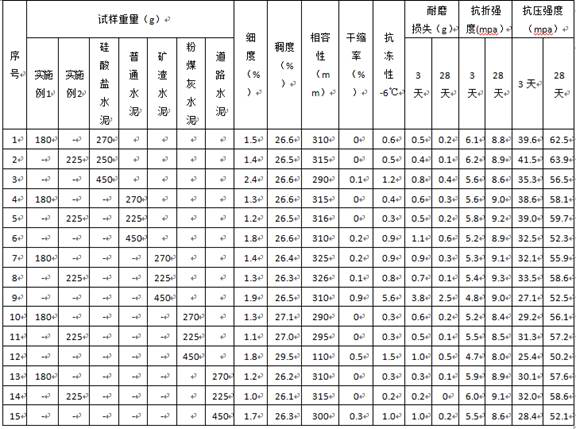

Examples

Embodiment 1

[0015] The invention discloses mineral powder prepared by using industrial waste slag neutralized slag, which is composed of the following substances in mass percentage: 90% neutralized slag, 10% nickel slag, waste slag discharged after the rare earth enterprises produce rare earth products. The above-mentioned nickel slag is the waste slag discharged from the nickel product enterprises after producing nickel products; wherein, the neutralization slag contains CaO, SiO 2 、Al 2 o 3 , Fe 2 o 3 , MgO and H 2 O, the water content is 60%.

[0016] The invention discloses a method for preparing slag by using industrial waste slag to neutralize slag. The neutralized slag and nickel slag are calculated as 90% of neutralized slag and 10% of nickel slag according to mass percentage, mixed and stirred evenly by equipment, and hydration reaction is carried out. Then it is dried in a drying kiln at 100°C to form a mineral powder product with a new mineral composition and a new crystal...

Embodiment 2

[0019] The invention discloses mineral powder prepared by using industrial waste slag neutralized slag, which is composed of the following mass percentages: 95% neutralized slag, 5% nickel slag, the waste slag discharged after the neutralized slag rare earth enterprise produces rare earth products, and the The above-mentioned nickel slag is the waste slag discharged from the nickel product enterprises after producing nickel products; wherein, the neutralization slag contains CaO, SiO 2 、Al 2 o 3 , Fe 2 o 3 , MgO and H 2 O, the water content is 60%.

[0020] The invention discloses a method for preparing slag using industrial waste slag neutralization slag. The neutralization slag and nickel slag are calculated as 95% of neutralization slag and 5% of nickel slag by mass percentage, and are mixed and stirred evenly by equipment to carry out hydration reaction. Then it is dried in a drying kiln at 300°C to form a mineral powder product with a new mineral composition and a ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com