High-elasticity high-temperature-resistant aerogel and preparation method thereof

A technology of high temperature resistance and airgel, which is applied in the direction of airgel preparation, botany equipment and methods, chemical instruments and methods, etc., to achieve the effect of high-efficiency oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

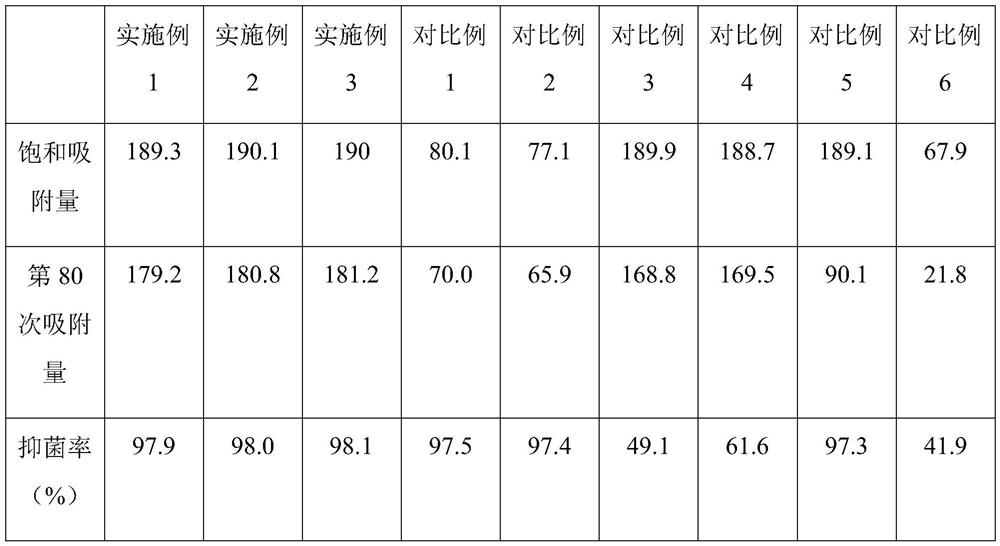

Examples

Embodiment 1

[0033] A method for preparing a high-elasticity and high-temperature-resistant aerogel, the preparation method of the high-elasticity and high-temperature-resistant aerogel mainly includes the following preparation steps:

[0034] (1) Collect livestock and poultry manure, add auxiliary materials with 0.2 times the mass of livestock and poultry manure, after stirring evenly, add strains with 0.005 times the mass of livestock and poultry manure, after stirring evenly, compost in the pretreatment shed, control the fermentation temperature to 70°C, Ferment for 20 days to obtain pretreated livestock and poultry manure;

[0035] (2) Place the pretreated livestock and poultry feces in a fixed bed pyrolysis device, heat to 100°C under a nitrogen atmosphere, keep warm for 2 minutes, then heat up to 250°C, keep warm for 30 minutes, and cool to room temperature to obtain a hydrophobic solid;

[0036] (3) Put the hydrophobic solid in a ball mill and mill it for 10 minutes, with a ball-to-...

Embodiment 2

[0052] A method for preparing a high-elasticity and high-temperature-resistant aerogel, the preparation method of the high-elasticity and high-temperature-resistant aerogel mainly includes the following preparation steps:

[0053] (1) Collect livestock and poultry manure, add auxiliary materials with 0.3 times the mass of livestock and poultry manure, after stirring evenly, add strains with 0.01 times the mass of livestock and poultry manure, after stirring evenly, compost in the pretreatment shed, control the fermentation temperature to 75°C, Ferment for 25 days to obtain pretreated livestock and poultry manure;

[0054] (2) Place the pretreated livestock and poultry feces in a fixed bed pyrolysis device, heat to 100°C under a nitrogen atmosphere, heat up to 300°C after holding for 4 minutes, and cool to room temperature after holding for 40 minutes to obtain a hydrophobic solid;

[0055] (3) Put the hydrophobic solid in a ball mill and mill it for 15 minutes with a ball-to-m...

Embodiment 3

[0071] A method for preparing a high-elasticity and high-temperature-resistant aerogel, the preparation method of the high-elasticity and high-temperature-resistant aerogel mainly includes the following preparation steps:

[0072] (1) collect livestock and poultry manure, add auxiliary materials of 0.24 times the mass of livestock and poultry manure, after stirring evenly, add bacteria strains of 0.0078 times the mass of livestock and poultry manure, after stirring evenly, compost in the pretreatment shed, control the fermentation temperature to 73°C, Ferment for 24 days to obtain pretreated livestock and poultry manure;

[0073] (2) Place the pretreated livestock and poultry manure in a fixed-bed pyrolysis device, and heat it to 100°C under a nitrogen atmosphere, heat it for 3 minutes, heat it up to 276° C, hold it for 33 minutes, and cool it to room temperature to obtain a hydrophobic solid;

[0074] (3) Put the hydrophobic solid in a ball mill and mill it for 14 minutes, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com