High-strength micro-expansion prestress anchoring grouting material and preparation method thereof

A grouting material and micro-expansion technology, which is used in the preparation of high-strength micro-expansion prestressed anchor grouting materials, and the field of high-strength micro-expansion prestressed anchor grouting materials, can solve problems such as hidden dangers in engineering, uncontrollable grouting quality, and national and people's property losses. , to achieve the effect of improving fluidity, avoiding segregation and stratification, and improving volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

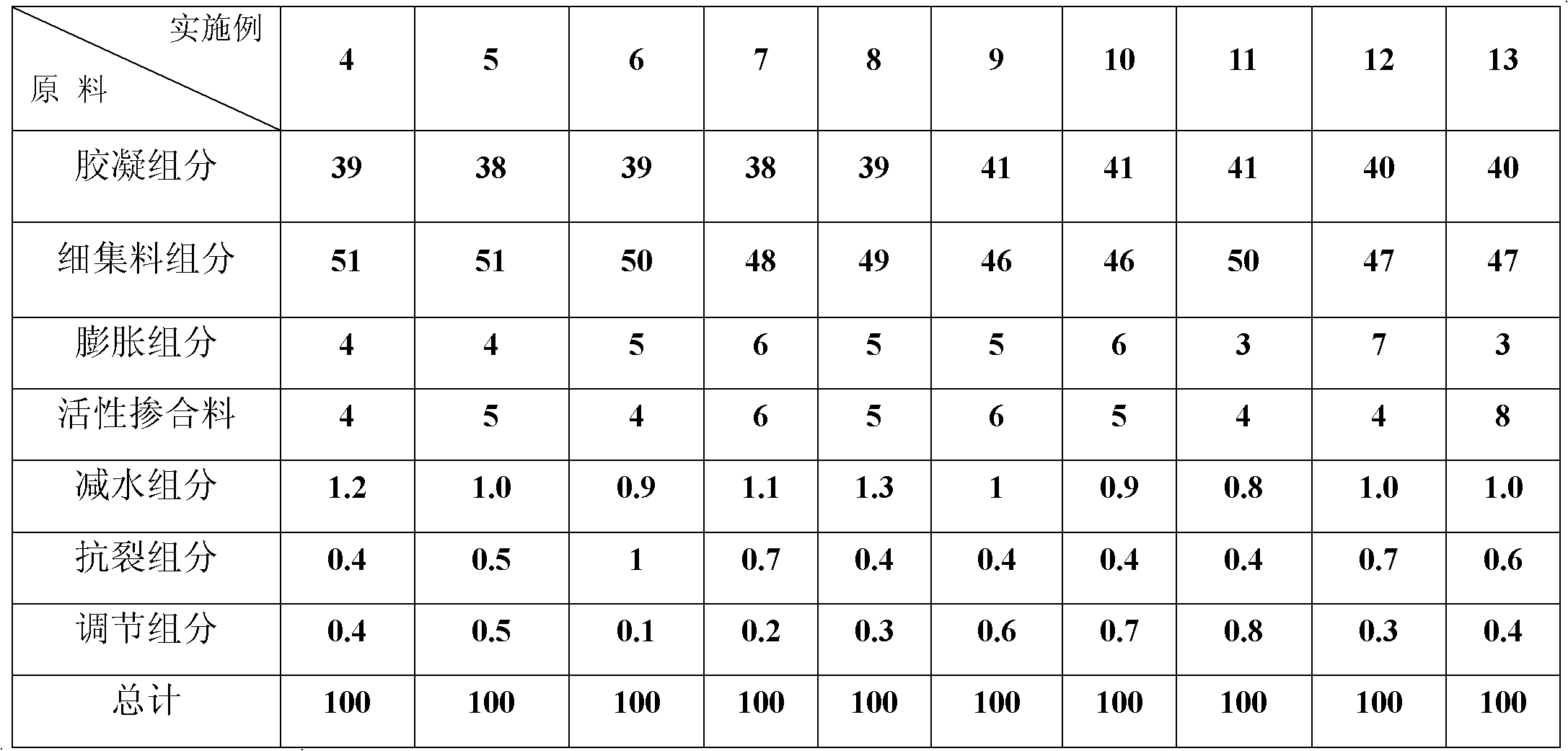

Examples

Embodiment 1

[0060] A high-strength micro-expansion prestressed anchor grouting material is composed of a gelling component, a fine aggregate component, an expansion component, an active admixture, an anti-cracking component, a water-reducing component and an adjusting component in a certain weight ratio A uniform powder material mixed and ground together, a high-strength micro-expansion prestressed anchor grouting material, which is made of the following raw materials in weight percentage:

[0061] Raw material % by weight Raw material % by weight

[0062] Gelling component 38% Fine aggregate component 50%

[0063] Intumescent component 5% Active admixture 5%

[0064] Water reducing component 0.9% Anti-cracking component 0.7%

[0065] Adjustment component 0.4%.

[0066] The gelling component is ordinary Portland cement.

[0067] The fine aggregate component is natural quartz sand, which is formed by mixing quartz sand with a particle size range of 20-40 mesh and 40-70 mesh at a ratio ...

Embodiment 2

[0080] A high-strength micro-expansion prestressed anchor grouting material is composed of a gelling component, a fine aggregate component, an expansion component, an active admixture, an anti-cracking component, a water-reducing component and an adjusting component in a certain weight ratio A uniform powder material mixed and ground together, a high-strength micro-expansion prestressed anchor grouting material, which is made of the following raw materials in weight percentage:

[0081] Raw material % by weight Raw material % by weight

[0082] Gel component 40% Fine aggregate component 48%

[0083] Intumescent component 4% Active admixture 6%

[0084] Water reducing component 1.2% Anti-cracking component 0.5%

[0085] Adjustment component 0.3%.

[0086] The gelling component is ordinary Portland cement.

[0087] The fine aggregate component is natural quartz sand, which is formed by mixing quartz sand with a particle size range of 20-40 mesh and 40-70 mesh at a ratio of 1...

Embodiment 3

[0097] A high-strength micro-expansion prestressed anchor grouting material is composed of a gelling component, a fine aggregate component, an expansion component, an active admixture, an anti-cracking component, a water-reducing component and an adjusting component in a certain weight ratio A uniform powder material mixed and ground together, a high-strength micro-expansion prestressed anchor grouting material, which is made of the following raw materials in weight percentage:

[0098] Raw material % by weight Raw material % by weight

[0099] Gel component 37% Fine aggregate component 51%

[0100] Intumescent component 5% Active admixture 5%

[0101] Water reducing component 1.2% Anti-cracking component 0.6%

[0102] Adjustment component 0.2%.

[0103] The gelling component is ordinary Portland cement.

[0104]The fine aggregate component is natural quartz sand, which is formed by mixing quartz sand with a particle size range of 20-40 mesh and 40-70 mesh at a ratio of 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com