High-performance cement and concrete and their production

A high-performance concrete, high-performance technology, used in cement production and other directions to achieve the effects of good fluidity, small loss over time and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

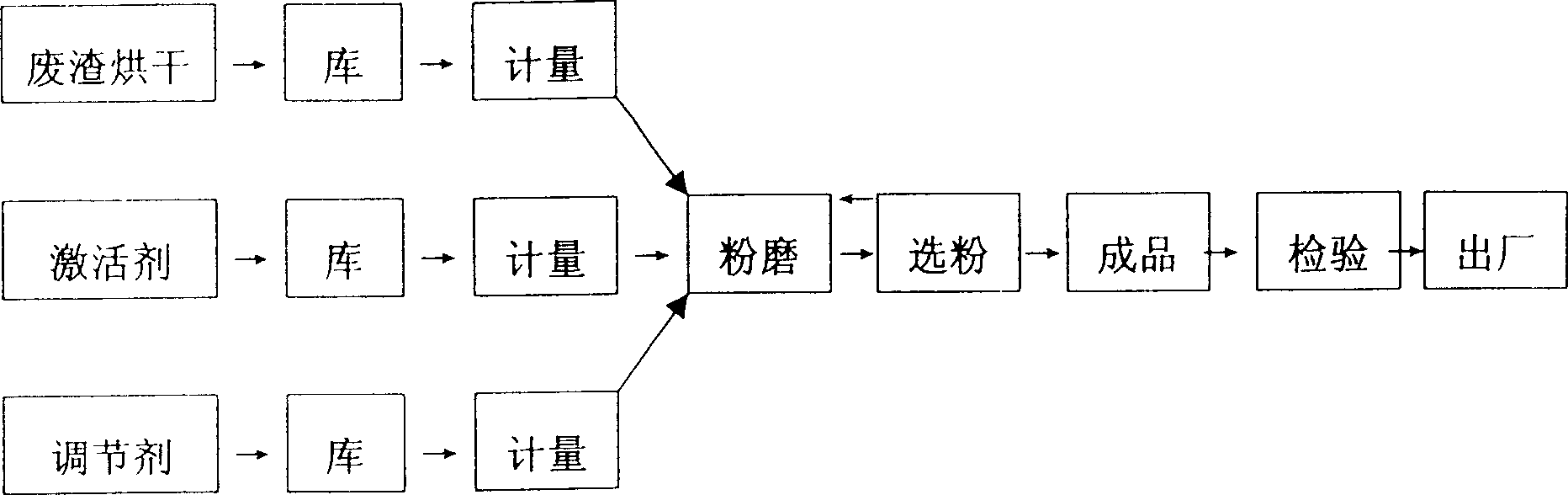

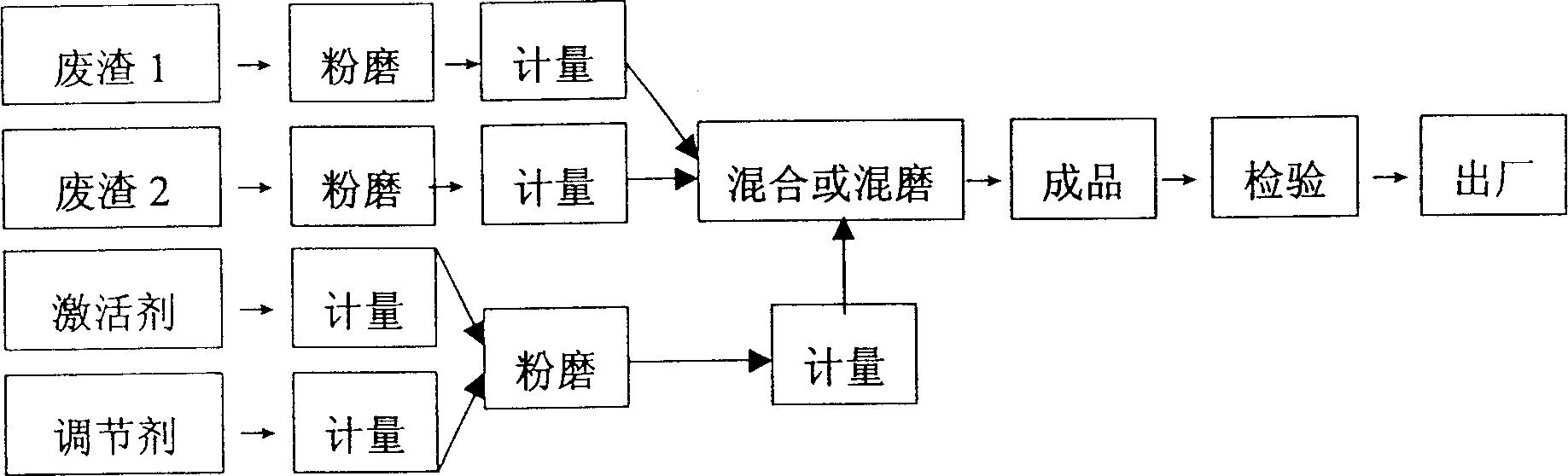

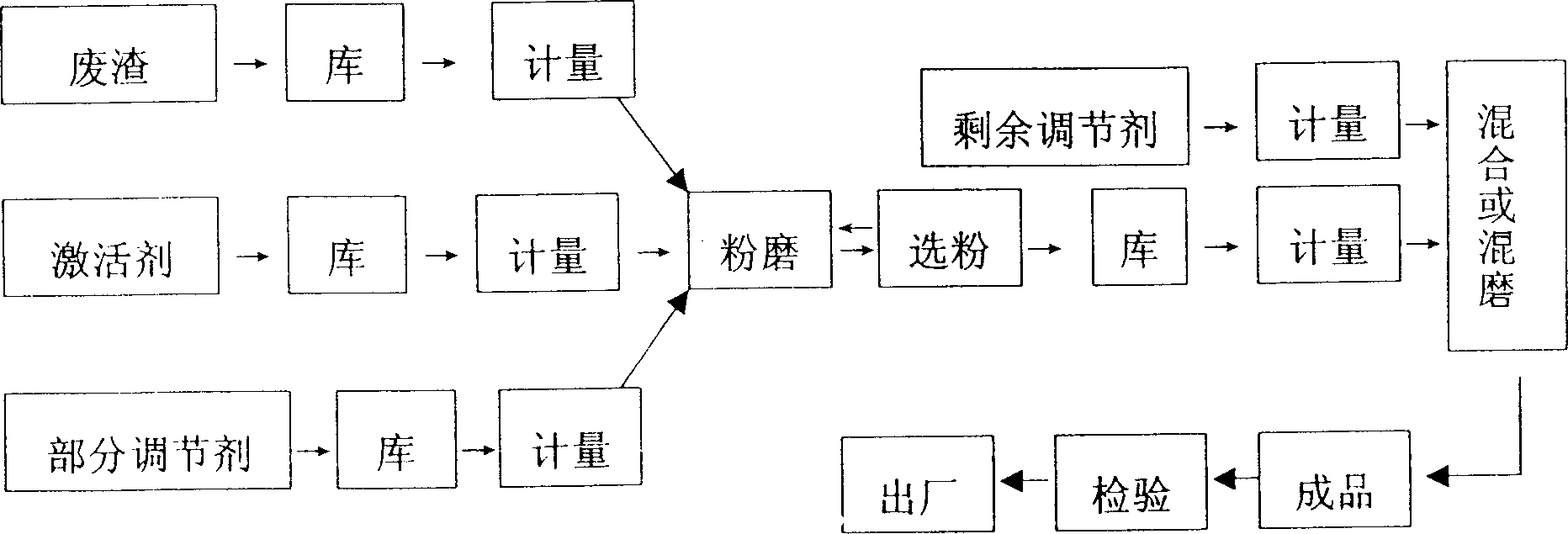

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Waste slag is furnace slag, manganese slag, slag, consumption 70%, activator is Portland cement clinker, unslaked lime, anhydrite, consumption 26%, a small amount of performance regulator is limestone 3%, trace performance regulator 1 %, large-scale production adopts process I, and its cement performance test results are shown in Table 1, and the cement's real strength label reaches 52.5 grades.

[0027] Compare table

[0028] It only needs to use 300kg / m2 to mix C30 and C45 anti-seepage pumping concrete with this cement 3 and 400kg / m 3 For cement, it is enough to control the initial slump of concrete to 170±10mm. The concrete proportion and properties are shown in Table 2.

[0029]

[0030] At the same time, the concrete has good economy, and the cost of the C30 concrete of the present invention is 10 yuan / m lower than that of the same C30 concrete prepared with other materials such as cement. 3 About, while C45 is about 20 yuan low...

Embodiment 2

[0031] Embodiment 2: waste residue is fly ash, slag, silicon slag, consumption 73%, and activator is portland cement clinker, natural dihydrate gypsum, consumption 25%, trace performance regulator 2%, and wherein 0.5% is in grinding The remaining 1.5% is added after grinding, and the production is carried out according to process III. The properties of the finished product are shown in Table 3, and the actual strength of the cement reaches 72.5 grades.

[0032] Compare table

area

m 2 / kg

SO 3

(%)

standard

consistency

(%)

install

Complete

sex

initial setting

time

h:m

final set

time

h:m

Pure pulp

Liquidity

mm

Liquidity

three days strength

MPa

twenty eight days strong

degree MPa

heat of hydration

KJ / kg

432

2.6

20

combine

grid

5:00

6:30

rise

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com