Ultrahigh-property cement-based material with low shrinkage and high toughness and preparation method thereof

A cement-based material, ultra-high performance technology, applied in the field of building materials, can solve the problems of structural safety and durability threats, affecting concrete work performance, large early plastic shrinkage value, etc., achieving good work performance, small early shrinkage, The effect of a small amount of cementitious material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

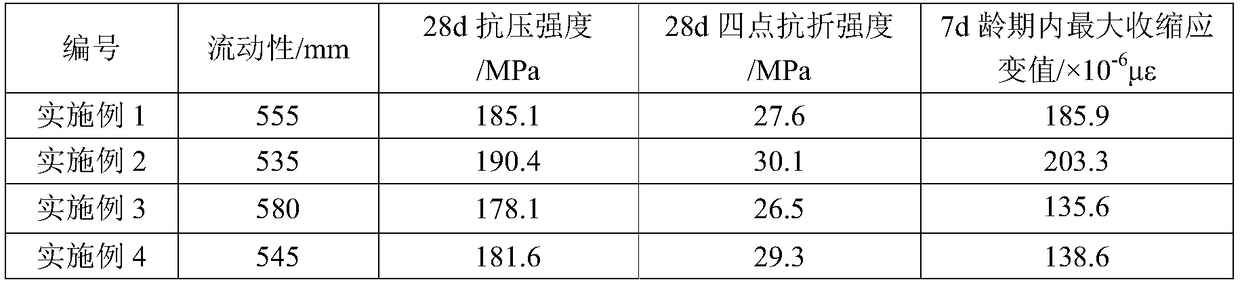

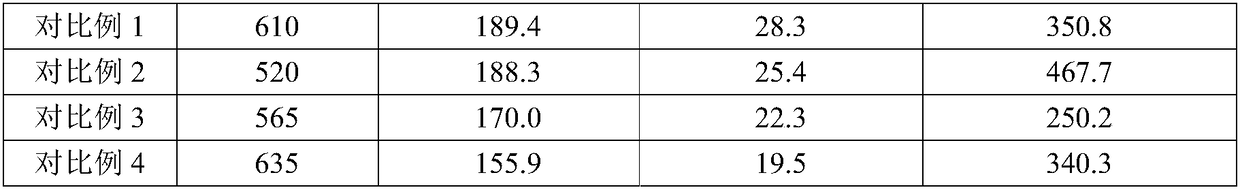

Examples

Embodiment 1

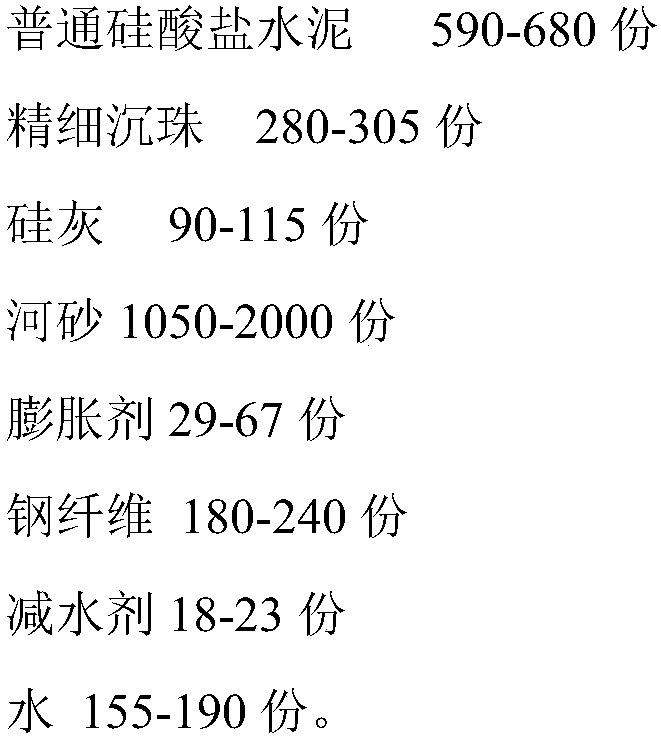

[0054] A low-shrinkage, high-toughness, ultra-high-performance cement-based material, comprising the following components in parts by weight:

[0055] Ordinary Portland cement 596 parts, fine beads 298 parts, silica fume 99 parts, river sand 1092 parts, expansion agent 30 parts, steel fiber 195 parts, polycarboxylate superplasticizer 20 parts, water 159 parts.

[0056] Preparation:

[0057] (1) Weigh the required materials, including: ordinary portland cement, fine beads, silica fume, river sand, expansion agent, microwire steel fiber, polycarboxylate superplasticizer and tap water;

[0058] (2) Wetting the mixer and the tools and molds used;

[0059] (3) Add the weighed ordinary Portland cement, fine beads, silica fume and expansion agent into a standard cement planetary mixer in turn for dry mixing, stir at a slow speed for 2 minutes, and mix evenly to obtain a mixed cementitious material;

[0060] (4) Add the weighed river sand into the mixed cementitious material in step...

Embodiment 2

[0064] A low-shrinkage, high-toughness, ultra-high-performance cement-based material, comprising the following components in parts by weight:

[0065] Ordinary Portland cement 596 parts, fine beads 298 parts, silica fume 99 parts, river sand 1092 parts, expansion agent 30 parts, steel fiber 234 parts, polycarboxylate superplasticizer 20 parts, water 159 parts.

[0066] Preparation:

[0067] (1) Weigh the required materials, including: ordinary portland cement, fine beads, silica fume, river sand, expansion agent, microwire steel fiber, polycarboxylate superplasticizer and tap water;

[0068] (2) Wetting the mixer and the tools and molds used;

[0069] (3) Add the weighed ordinary Portland cement, fine beads, silica fume and expansion agent into a standard cement planetary mixer in turn for dry mixing, stir at a slow speed for 2 minutes, and mix evenly to obtain a mixed cementitious material;

[0070] (4) Add the weighed river sand into the mixed cementitious material in step...

Embodiment 3

[0074] A low-shrinkage, high-toughness, ultra-high-performance cement-based material, comprising the following components in parts by weight:

[0075] 590 parts of ordinary Portland cement, 295 parts of fine beads, 98 parts of silica fume, 1082 parts of river sand, 59 parts of expansion agent, 195 parts of steel fiber, 20 parts of polycarboxylate superplasticizer, and 157 parts of water.

[0076] Preparation:

[0077] (1) Weigh the required materials, including: ordinary portland cement, fine beads, silica fume, river sand, expansion agent, microwire steel fiber, polycarboxylate superplasticizer and tap water;

[0078] (2) Wetting the mixer and the tools and molds used;

[0079] (3) Add the weighed ordinary Portland cement, fine beads, silica fume and expansion agent into a standard cement planetary mixer in turn for dry mixing, stir at a slow speed for 2 minutes, and mix evenly to obtain a mixed cementitious material;

[0080] (4) Add the weighed river sand into the mixed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com