High-early-strength, freeze-proofing and high-performance polycarboxylate water reducer

A technology of polycarboxylate and water reducer, which is applied in the preparation of early strength antifreeze polycarboxylate water reducer, early strength antifreeze polycarboxylate water reducer, concrete and ready-mixed mortar, and can solve the problem of Reduce the problems of antifreeze performance, unstable bubbles, and failure to meet the air content requirements, so as to achieve the effects of improving antifreeze performance, improving durability, and reducing loss over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

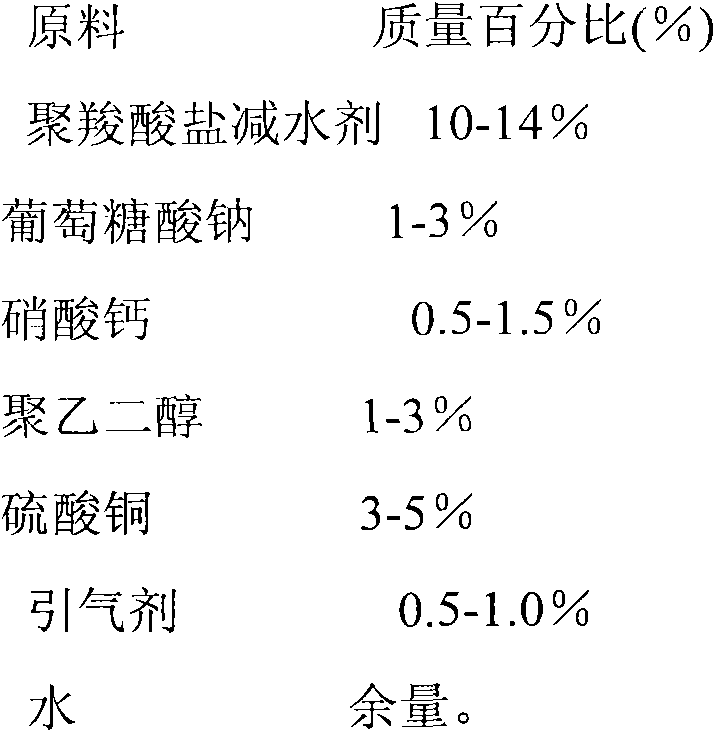

[0019] An early-strength antifreeze polycarboxylate superplasticizer, the components in the priority range are formulated according to the following mass percentages:

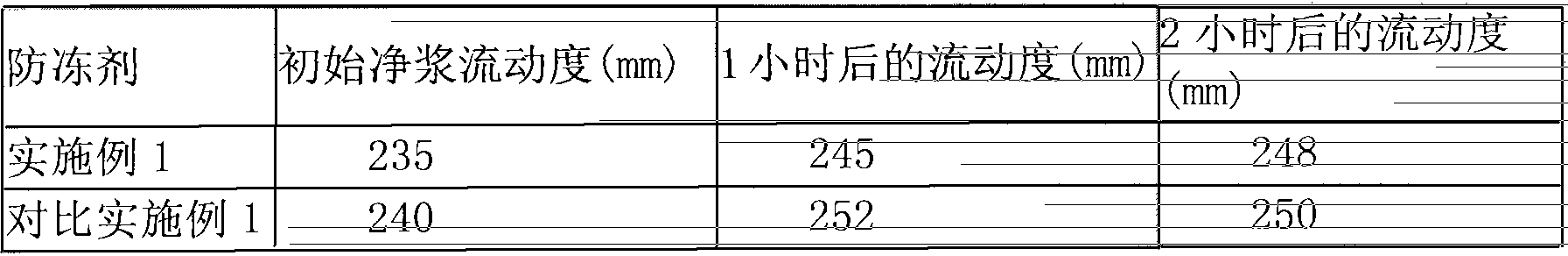

[0020]

[0021]

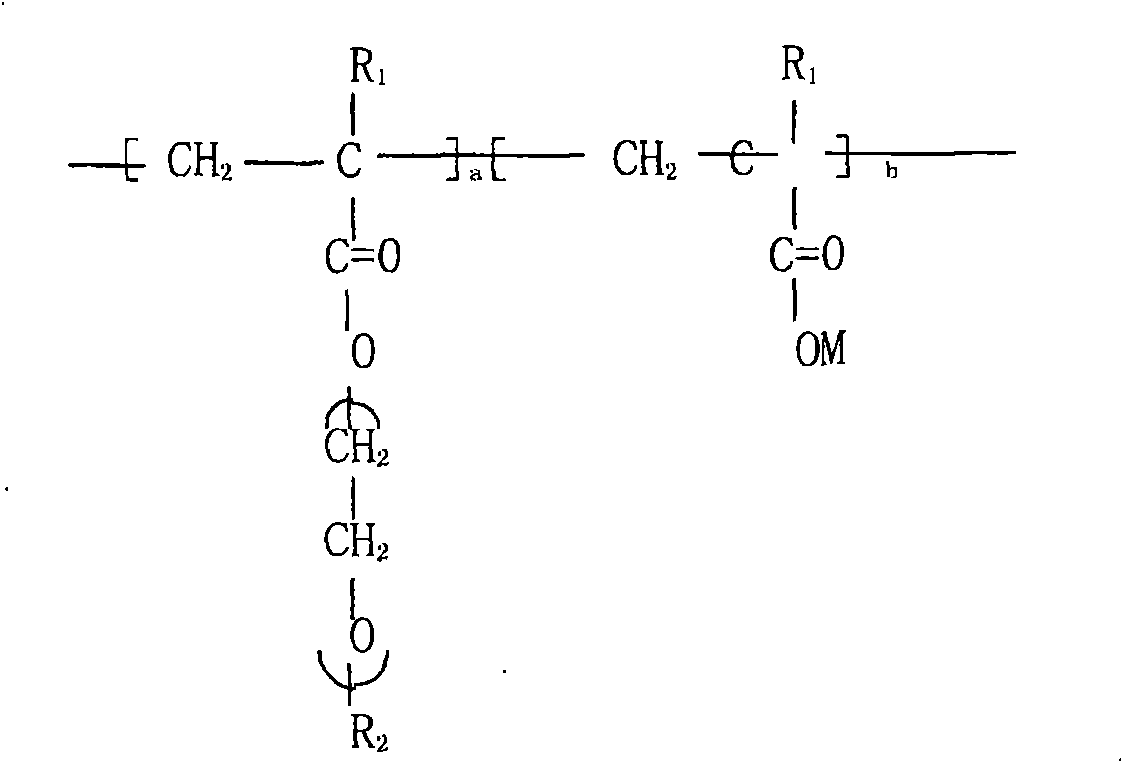

[0022] An early-strength antifreeze polycarboxylate high-performance water reducer, the polycarboxylate high-performance water reducer is a graft copolymer of the following general formula, and its structural formula is:

[0023]

[0024] where: R 1 for -CH 3 or H; R 2 is H or an alkyl group with 1-4 carbon atoms; M is H, a monovalent metal ion, a divalent metal ion, an ammonium group or an amine group; The molecular weight of the product is determined; n is the average molar number of ethylene oxide addition 90-200.

[0025] A kind of preparation method of early-strength antifreeze type polycarboxylate superplasticizer, its steps are:

[0026] (1) Esterification reaction: Add 80Kg of dissolved methoxy polyethylene glycol (molecular weight is 1500) to the reactor, heat up and star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com