Light aggregate concrete pumping agent

A light aggregate concrete and pumping agent technology, applied in the field of pumping agent, can solve the problems of low success rate, short pumping distance, unsatisfactory effect of light aggregate concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

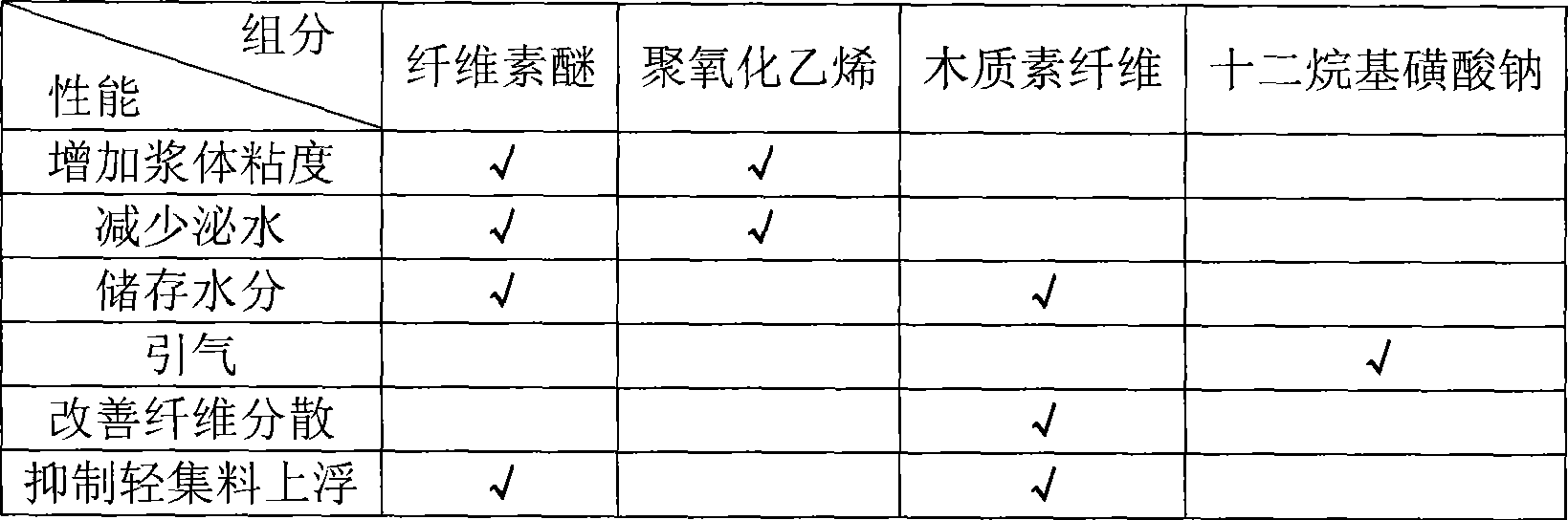

Method used

Image

Examples

Embodiment 1

[0046] A light aggregate concrete pumping agent, prepared by putting 0.8kg of cellulose ether, 0.1kg of polyethylene oxide, 1kg of sodium dodecylsulfonate, 5kg of lignin fiber, and 13kg of silica fume into a mixer for 240 seconds . The cellulose ether is methyl hydroxyethyl cellulose ether with a viscosity of 30,000-50,000mPa·S; the molecular weight of the polyethylene oxide is 500,000-1,000,000, and the lignin fibers are flocculent lignin fibers. Described sodium dodecylsulfonate is commercially available technical pure sodium dodecylsulfonate, and the specific surface area of described silica fume is 10000-25000m 2 / kg.

[0047] When in use, first weigh 1.12kg of the pumping agent, and when stirring, first put all the raw materials (Table 9) into the mixer in any order, and then stir for more than 3 minutes to obtain light aggregate concrete. The concrete mix ratio and properties are shown in the table. 9. Table 10. Table 11 is the lightweight aggregate concrete without...

Embodiment 2

[0055] Embodiment 2: A kind of light aggregate concrete pumping agent, by cellulose ether 1kg, polyoxyethylene 0.2kg, lignin fiber 10kg, sodium lauryl sulfonate 1.5kg, silica fume 14kg, drop into single horizontal axis to force Prepared by blending in a blender for 240 seconds. The cellulose ether is methyl hydroxypropyl cellulose ether with a viscosity of 30,000-50,000mPa·S; the molecular weight of the polyethylene oxide is 500,000-1,000,000, and the lignin fibers are flocculent lignin fibers. Described sodium dodecylsulfonate is commercially available technical pure sodium dodecylsulfonate, and the specific surface area of described silica fume is 10000-25000m 2 / kg.

[0056] When in use, first weigh 2kg of the pumping agent, and when stirring, first put all the raw materials (Table 12) into the mixer in any order, and then stir for more than 3 minutes to obtain light aggregate concrete. The concrete mix ratio and properties are shown in Table 12 respectively. , Table 13...

Embodiment 3

[0064] Embodiment 3: A kind of light aggregate concrete pumping agent, by cellulose ether 1.1kg, polyoxyethylene 0.4kg, lignin fiber 3kg, upper dialkyl sodium sulfonate 0.5kg, silica fume 15kg, drop into single horizontal shaft Prepared by blending in a forced blender for 240 seconds. The cellulose ether is methyl hydroxyethyl cellulose ether with a viscosity of 30,000-50,000mPa·S; the molecular weight of the polyethylene oxide is 500,000-1,000,000, and the lignin fibers are flocculent lignin fibers. Described sodium dodecylsulfonate is commercially available technical pure sodium dodecylsulfonate, and the specific surface area of described silica fume is 10000-25000m 2 / kg.

[0065] When in use, first weigh 2kg of the pumping agent, and when stirring, first put all the raw materials (Table 15) into the mixer in any order, and then stir for more than 3 minutes to obtain light aggregate concrete. The concrete mix ratio and properties are shown in Table 15 respectively. , Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Dry apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com