Polyethers ultra early and strong type concrete superplasticizer

A super-early-strength type and superplasticizer technology, applied in the field of concrete admixtures, can solve problems such as poor storage stability, affecting application, and reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

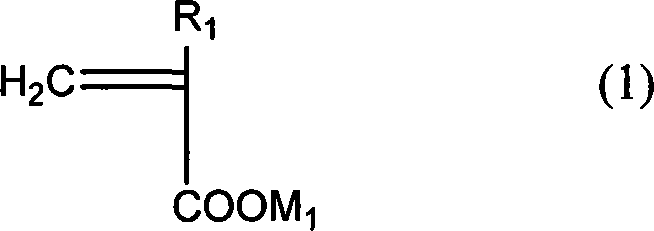

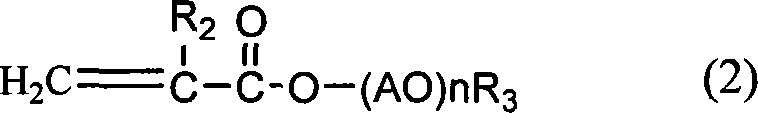

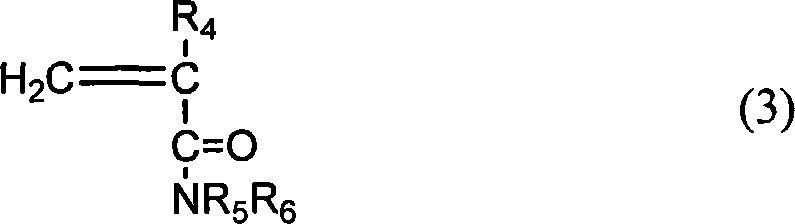

Method used

Image

Examples

application Embodiment 1

[0074] Onoda 525R.P.II cement is used, the sand is standard sand, the mix ratio is 450g of cement, 1350g of standard sand, and 170g of water. Listed in table 3 is the impact of copolymer on the setting time of cement slurry and mortar strength, as seen from table 3, polyether concrete superplasticizer of the present invention has promoted cement early hydration, has improved cement-based material Early mechanical properties. In contrast, short-chain polymers such as Comparative Example 3 have low early strength, and the strength without adding functional defoaming components is even lower.

[0075] table 3

[0076]

application Embodiment 2

[0078] Cement is Onoda 525R.P.II, sand is fineness modulus M x = 2.6 medium sand, the stones are crushed stones with a particle size of 5-20mm and continuous gradation. Concrete water reducing rate, air content, setting time test methods refer to the relevant provisions of GB8076-97 "Concrete Admixtures". Concrete compressive strength and flexural strength refer to the relevant provisions of GB / T50081-2002 "Standards for Test Methods of Mechanical Properties of Ordinary Concrete". Concrete drying shrinkage is carried out with reference to the relevant provisions of GBJ82-85 "Ordinary Concrete Long-Term Performance and Durability Test Method", the test results are shown in Table 4, the polyether concrete superplasticizer of the present invention has excellent dispersion performance, and can significantly Improve the early strength of concrete. According to the test results, the 3d compressive strength can be increased by 140-200% relative to the benchmark, and the 28d compress...

application Embodiment 3

[0082] According to the "Medium and Long-term Railway Network Plan" approved by the State Council, my country will build more than 12,000 kilometers of passenger dedicated lines. Due to the needs of construction, passenger dedicated lines have proposed a concrete prefabricated component with super early strength, which requires 16h concrete under normal temperature curing conditions. The strength reaches 48MPa (using special cement). . The proportion of concrete is cement: water: fine aggregate: coarse aggregate = 427: 135: 691: 1127. The test results are shown in Table 5. It can be seen from the data in the table that the polyether concrete superplasticizer of the present invention can significantly improve the early strength of concrete, the 16h compressive strength has reached about 40% of the 28d strength, and the 1d compressive strength can reach more than 60% of the 28d. Since the cement on the project site is specially supplied ultra-fine cement (the specific surface are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com