Composite high-efficient environment-friendly powdery cement grinding aid

A cement grinding aid and environment-friendly technology, which is applied in the field of compound high-efficiency and environment-friendly powder cement grinding aid, can solve the problems of poor reinforcement effect, poor grinding aid effect, and damage to concrete performance, and achieve the effect of low alkali content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Firstly, take 1000Kg of citric acid slag, and after ultrasonic treatment for 2 hours, crush it to about 40 mesh with a pulverizer to obtain the treated citric acid slag; the ultrasonic frequency is 40KHz, and the power is 50KW.

[0030] Add 60Kg of molasses, 10Kg of triethanolamine and 30Kg of triisopropanolamine into a stirring tank, add water to make a 60% aqueous solution; add 100Kg of calcium lignosulfonate to a stirring tank, add water to make a 30% aqueous solution.

[0031] Weigh 450Kg of the citric acid slag after the above treatment, add 150Kg of fly ash into the conical mixer, add the above solution while stirring, and then stir for 10 minutes; weigh 80Kg of anhydrous sodium sulfate, 70Kg of sodium silicate, and 60Kg of slaked lime in turn Add to the conical mixer while stirring; finally stir for 15 minutes, and the finished product is discharged.

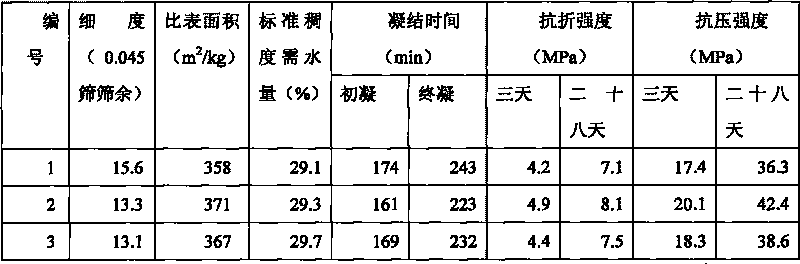

[0032] The above-mentioned composite high-efficiency and environment-friendly powder cement grinding aid is used...

example 2

[0038] First, take 1000Kg of citric acid slag, and after ultrasonic treatment for 4 hours, crush it to about 40 mesh with a pulverizer to obtain the treated citric acid slag; the ultrasonic frequency is 30KHz, and the power is 40KW.

[0039] Add 80Kg of molasses, 20Kg of triethanolamine and 10Kg of triisopropanolamine into a stirring tank, add water to make a 60% aqueous solution; add 160Kg of calcium lignosulfonate to a stirring tank, add water to make a 30% aqueous solution.

[0040] Weigh 420Kg of the citric acid slag after the above treatment, add 100Kg of fly ash into the conical mixer, add the above solution while stirring, and then stir for 10 minutes; weigh 50Kg of anhydrous sodium sulfate, 100Kg of sodium silicate, and 60Kg of slaked lime in turn Add to the conical mixer while stirring; finally stir for 15 minutes, and the finished product is discharged.

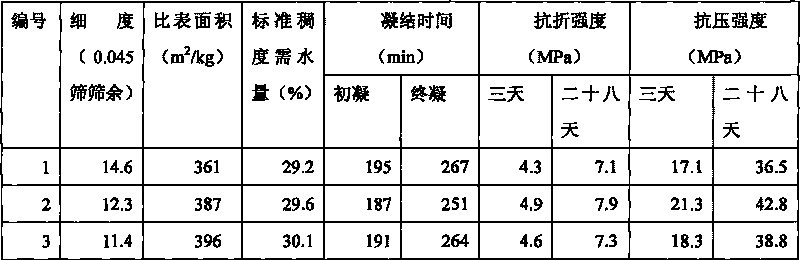

[0041] The above-mentioned composite high-efficiency and environment-friendly powder cement grinding aid is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com