Sludge treatment equipment

A sludge treatment and equipment technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc., can solve the problem of damage, freezing of sewage, and inability to store water-containing sludge evenly and other problems, to prevent damage and reduce the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

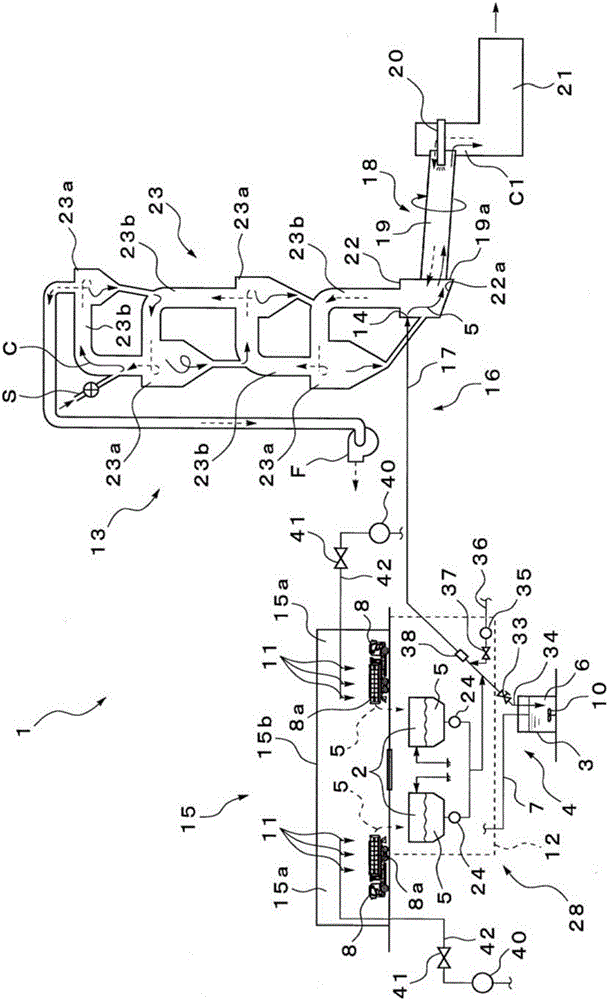

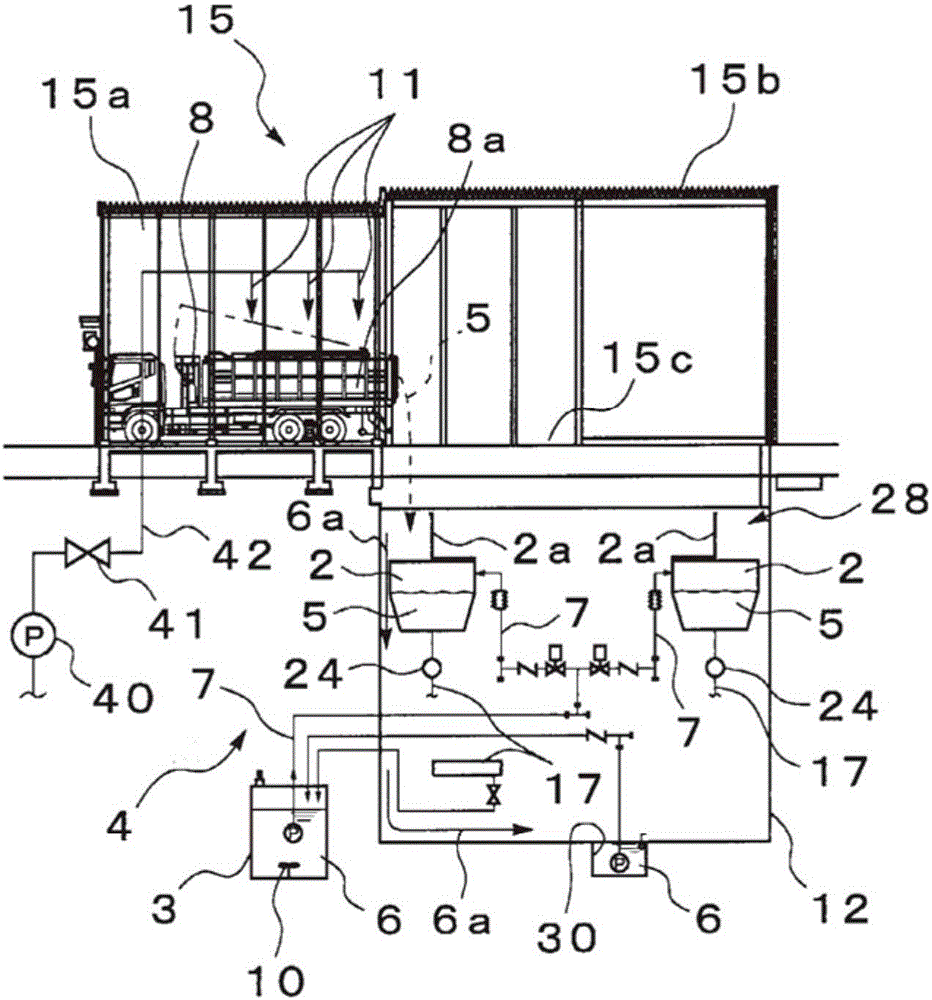

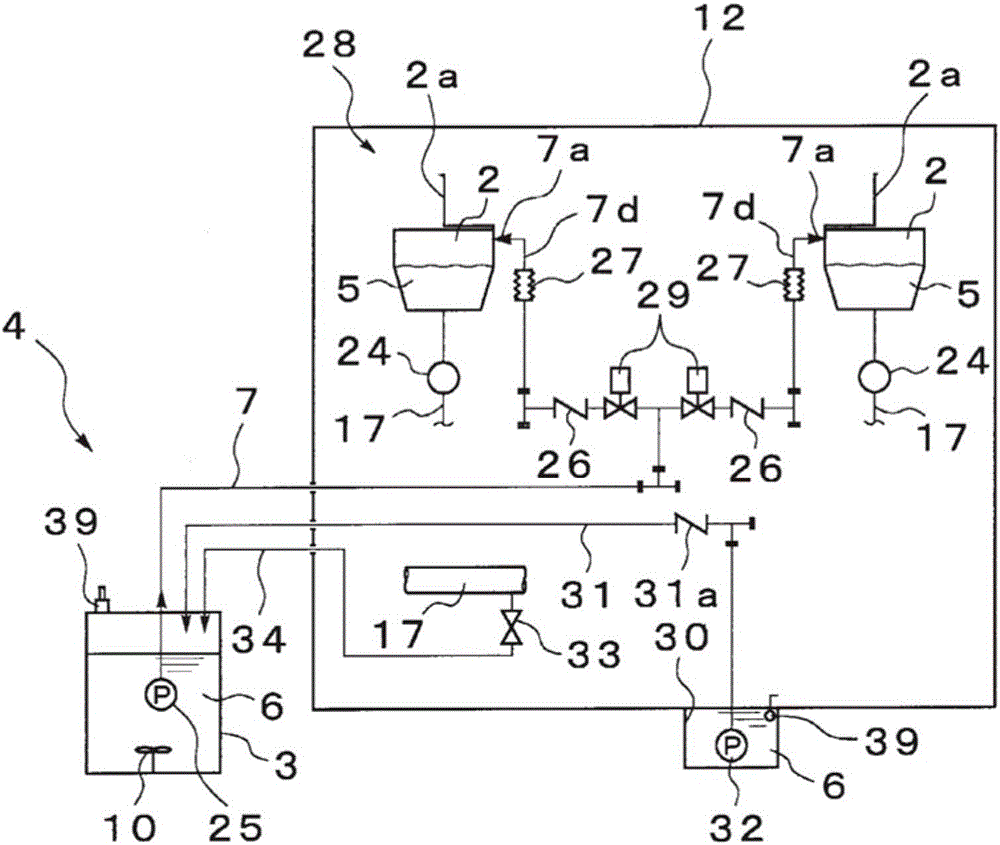

[0030] Such as figure 1 As shown, a sludge treatment facility 1 according to an embodiment of the present invention is schematically configured to include a cement manufacturing facility (cement manufacturing process) 13 having a dry-process rotary kiln 18 and a preheater for preheating cement raw material C 23; sludge receiving equipment 15, which receives the truck 8 that carries the water-containing sludge 5 from the sewage treatment plant; spraying device 11, which is equipped in the sludge receiving equipment 15; sludge bin accommodation equipment 28, which has sludge silo 2 and sewage recovery tank 3, storing water-containing sludge 5 in the sludge silo 2, and the sewage recovery tank 3 recovers and stores the sludge when cleaning the sludge silo 2 or the piping connected to the sludge silo 2 Sewage 6 ; and a sludge input mechanism 16 that injects the hydrous sludge 5 from the kiln tail 19 a side of the dry rotary kiln 18 through the sludge introduction pipe 17 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com