Method for preparing ordinary portland cement by taking gold mine tailings as raw materials

A technology for ordinary Portland cement and gold mine tailings, applied in the field of building materials, can solve the problems of poor activity, restricting industrial application, reducing cement strength, etc., and achieve the effects of compact structure, low price and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

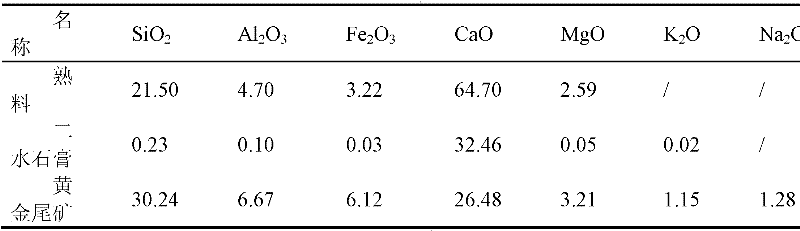

Image

Examples

Embodiment 1

[0015] The mass ratio of raw material powder is w (cement clinker): w (gypsum): w (gold tailings): w (activator) = 55: 4: 34: 7; Mix evenly and grind finely, and mix cement clinker and gypsum according to a certain proportion, mix uniformly and grind finely, the fineness is less than 5% after passing through the 80μm sieve, and then mix the four kinds of materials evenly after grinding. The prepared Portland cement has an initial setting time of 2 hours and 25 minutes, a final setting time of 4 hours and 10 minutes, a three-day flexural strength of 5.4MPa, a compressive strength of 28.7MPa, and a 28-day flexural strength The strength is 7.8MPa, the compressive strength is 45.8MPa, the stability is qualified, and it can meet the national standard of No. 42.5 cement. The activator used in the present invention is prepared from liquid A and liquid B, which are prepared separately; liquid A is uniformly prepared by mixing deionized water sodium salt solution, complexing agent, pH ...

Embodiment 2

[0020] The mass ratio of raw material powder is w (cement clinker): w (gypsum): w (gold tailings): w (activator) = 40: 10: 40: 10; Mix evenly and grind finely, and mix cement clinker and gypsum according to a certain proportion, mix uniformly and grind finely, the fineness is less than 5% after passing through the 80μm sieve, and then mix the four kinds of materials evenly after grinding. The prepared Portland cement has an initial setting time of 1 hour and 50 minutes, a final setting time of 3 hours and 50 minutes, a three-day flexural strength of 4.8MPa, a compressive strength of 24.7MPa, and a 28-day flexural strength The strength is 7.2MPa, the compressive strength is 42.8MPa, the stability is qualified, and it can meet the national standard of No. 42.5 cement. The activator used in the present invention is prepared from liquid A and liquid B, which are prepared separately; liquid A is uniformly prepared by mixing deionized water sodium salt solution, complexing agent, pH...

Embodiment 3

[0022] The mass ratio of raw material powder is w (cement clinker): w (gypsum): w (gold tailings): w (activator) = 50: 5: 35: 10; Mix evenly and grind finely, and mix cement clinker and gypsum according to a certain proportion, mix uniformly and grind finely, the fineness is less than 5% after passing through the 80μm sieve, and then mix the four kinds of materials evenly after grinding. The prepared Portland cement has an initial setting time of 2 hours and 10 minutes, a final setting time of 4 hours and 05 minutes, a three-day flexural strength of 5.8MPa, a compressive strength of 27.5MPa, and a 28-day flexural strength The strength is 7.2MPa, the compressive strength is 43.8MPa, the stability is qualified, and it can meet the national standard of No. 42.5 cement. The activator used in the present invention is prepared from liquid A and liquid B, which are prepared separately; liquid A is uniformly prepared by mixing deionized water sodium salt solution, complexing agent, pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com