Production method of nickel slag composite portland cement

A composite silicate and production method technology, which is applied in the field of inorganic non-metallic materials, can solve the problems of large land occupation and environmental pollution, and achieve the effects of improving strength, considerable economic benefits, and reducing liquid phase viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

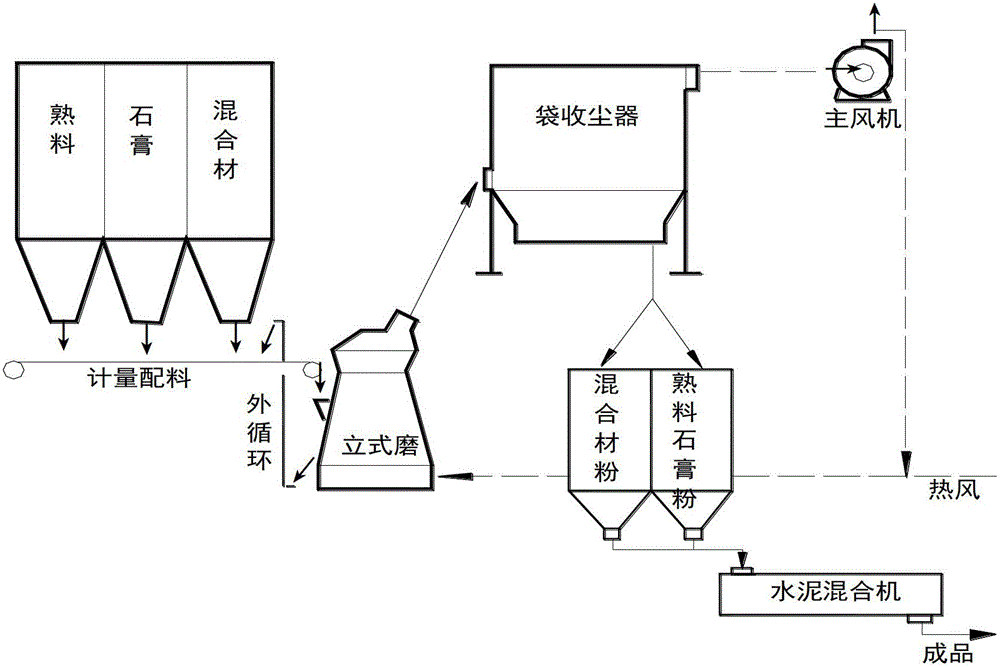

Method used

Image

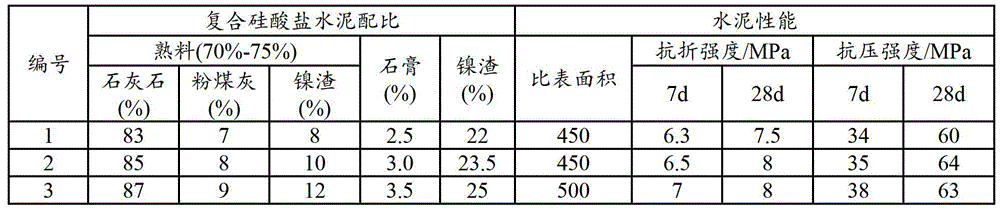

Examples

Embodiment Construction

[0019] According to the actual background and composite silicate production technology, the present invention proposes a novel method for preparing composite cement, using limestone, coal ash and ferronickel slag to prepare cement clinker, a certain amount of ferronickel slag as admixture, and an appropriate amount of Gypsum is used as a raw material for composite Portland cement.

[0020] According to the research on nickel slag instead of iron powder in cement clinker, it is shown that nickel slag contains a small amount of metal ions, such as Ni, Cu, Co and other elements, which play a positive role in reducing the minimum eutectic point temperature and liquid viscosity of clinker. It can improve the burnability of raw meal, so it is very beneficial to the formation of clinker minerals.

[0021] The nickel slag quenched by water quenching, because its glass phase contains a small amount of CaO, Al 2 o 3 , so in alkaline media (such as the hydration product Ca(OH) of Portl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com