Compound coal ash for concrete

A technology for fly ash and concrete, applied in the field of construction, can solve the problems of air pollution, large dust, difficult water control, etc., and achieve the effects of improving mechanical properties and durability, environmental protection, energy saving and emission reduction, and saving resources and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

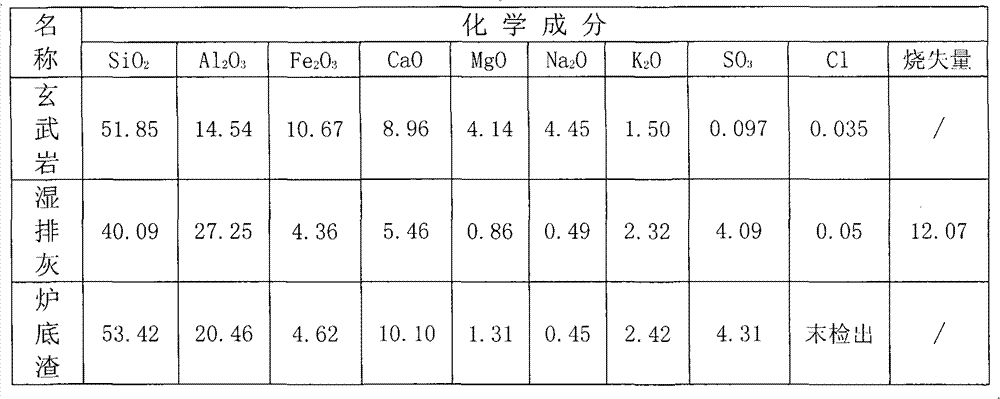

[0013] The chemical compositions of basalt, wet-drained fly ash and bottom slag are shown in Table 1:

[0014] Table 1

[0015]

[0016] Take 65kg of basalt and crush it into crushed stones below 50mm, then add 10kg of furnace bottom slag to the basalt crushed stones and 25kg of wet-discharged fly ash with a moisture content of 18% in proportion, and then enter the ball mill system for grinding processing. The fineness is controlled at a 45 micron square hole sieve and the sieve residue is less than 15%. During the grinding process, the fluidized furnace is used to convey hot air to dry the incoming grinding materials. At the same time, it is necessary to ensure the normal storage and transportation of the outgoing grinding materials. The water content is less than 0.5%, and the composite fly ash for concrete is obtained.

Embodiment 2

[0018] The chemical composition of basalt, wet-discharging fly ash, and furnace bottom slag is the same as in Example 1.

[0019] Take 40kg of basalt and crush it into crushed stones below 50mm, then add 20kg of furnace bottom slag to the basalt crushed stones and 40kg of wet fly ash with a moisture content of 20% in proportion, and then enter the vertical roller mill system for grinding. The fineness of the grinding material is controlled at 45 micron square hole sieve and the sieve is less than 15%. During the grinding process, the boiling furnace is used to convey hot air to dry the grinding material. The moisture content of the ground material is less than 0.5%, and the composite fly ash for concrete is obtained.

Embodiment 3

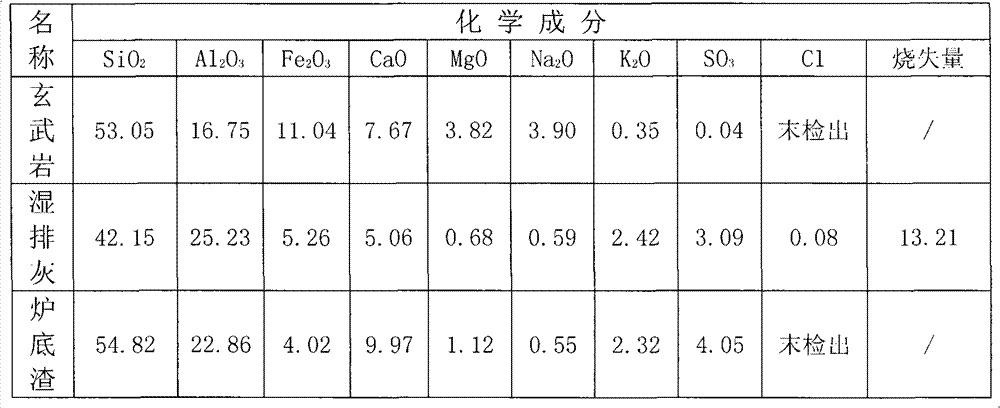

[0021] The chemical compositions of basalt, wet-drained fly ash and bottom slag are shown in Table 2:

[0022] Table 2

[0023]

[0024] Take 40kg of basalt and crush it into crushed stones below 50mm, then add 27kg of furnace bottom slag to the basalt crushed stones and 33kg of wet fly ash with a moisture content of 22% in proportion, and then enter the vertical roller mill system for grinding. The fineness of the grinding material is controlled at 45 micron square hole sieve and the sieve is less than 15%. During the grinding process, the boiling furnace is used to convey hot air to dry the grinding material. The moisture content of the ground material is less than 0.5%, and the composite fly ash for concrete is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com