52.5-grade slag portland cement and preparation method thereof

A technology of portland cement and steel slag, which is applied in the field of comprehensive utilization of solid waste and building materials, to achieve the effects of improving particle gradation, increasing service life, and reducing heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Taking 100g of the prepared sample as 100%:

[0027] A. Take ultra-fine steel slag powder 28%; density 2.90g / m 3 , specific surface area 620m 2 / kg;

[0028] B. Take 2% of high-grade semi-hydrated desulfurized gypsum from a factory in Shanghai, SO 3 Content 52%, hemihydrate gypsum (β-CaSO 4 1 / 2H 2 O) content of 95%;

[0029] C. Take 70% of 52.5 grade Portland cement from a factory in Jiangsu, the 3-day strength is 33.9, and the 28-day strength is 58.7;

[0030] After the above three components are uniformly mixed, it becomes 52.5 grade steel slag portland cement. According to GB175-2007 General Portland Cement National Standard, the strength of 52.5-grade steel slag Portland cement samples was tested, and the test results are shown in Table 1.

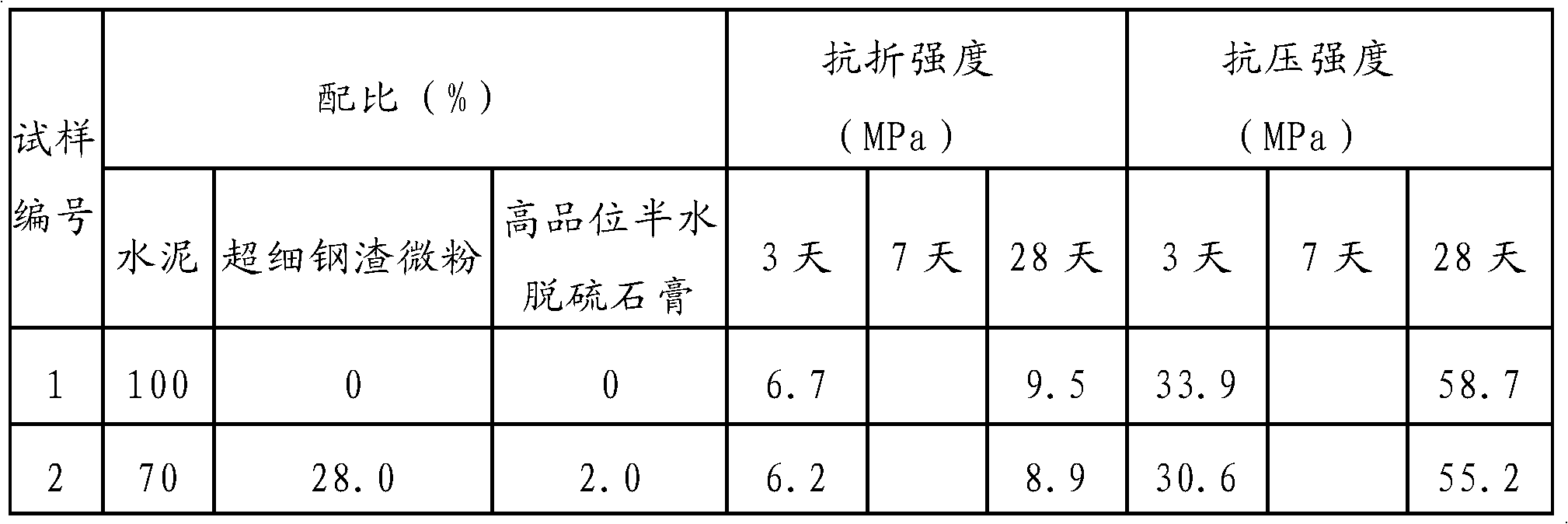

[0031] Table 1: Test results of 52.5 grade steel slag portland cement samples

[0032]

Embodiment 2

[0034] Taking 100g of the prepared sample as 100%:

[0035] A. Take 35% ultra-fine steel slag powder; density 2.92g / m 3 , specific surface area 695m 2 / kg;

[0036] B. Take 5% of high-grade semi-hydrated desulfurized gypsum from a factory in Shanghai, SO 3 Content 50%, hemihydrate gypsum (β-CaSO 4 1 / 2H 2 O) content 89%;

[0037] C. Take 60% of 52.5 grade Portland cement from a factory in Jiangsu, the 3-day strength is 35.1, and the 28-day strength is 60.2;

[0038] After the above three components are uniformly mixed, it becomes 52.5 grade steel slag portland cement. According to GB175-2007 General Portland Cement National Standard, the strength of 52.5-grade steel slag Portland cement samples was tested, and the test results are shown in Table 2.

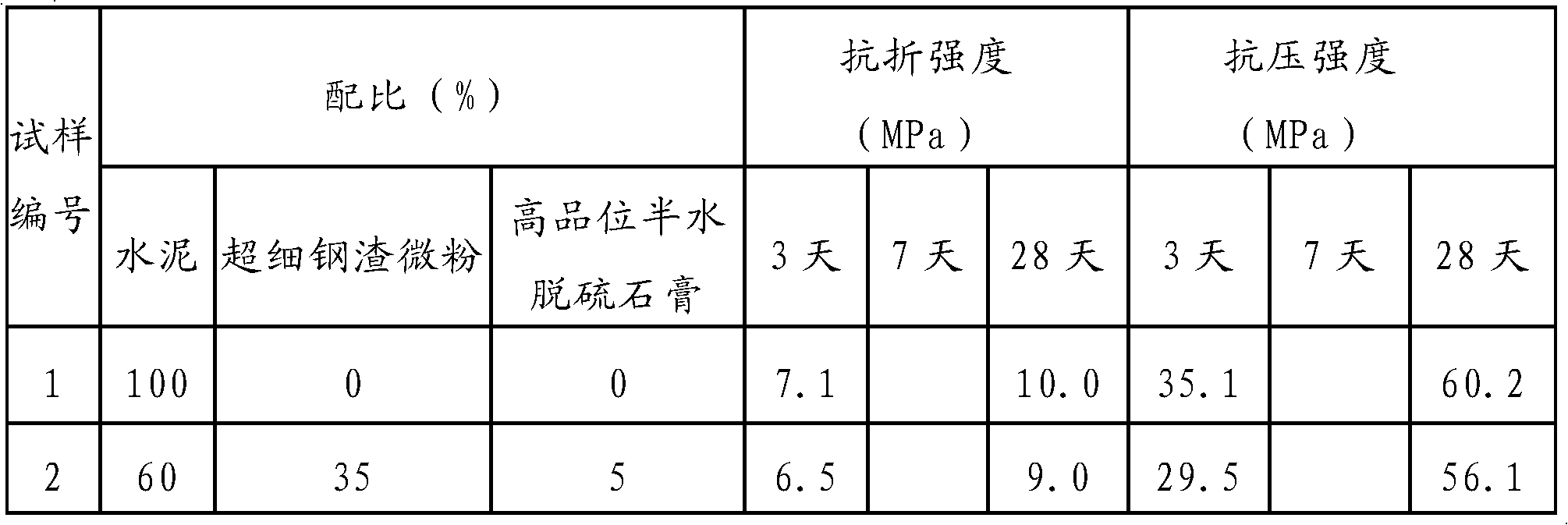

[0039] Table 2: Test results of 52.5 grade steel slag portland cement samples

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com