Preparation method of sulfoaluminate Belite cement

The technology of Belite sulfoaluminate and special sulfoaluminate is applied in the field of preparation of Belite sulfoaluminate cement, which can solve the problems of high energy consumption, environment and the like, achieve low energy consumption, low calcination temperature, The effect of solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

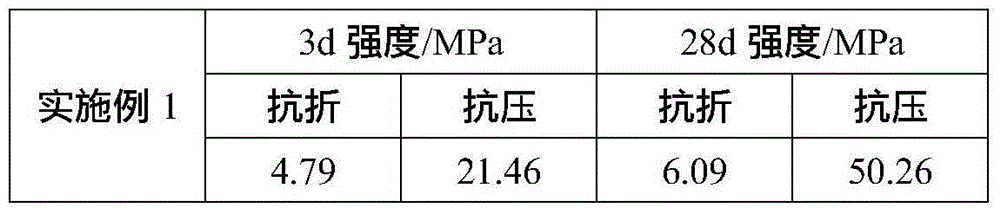

[0019] The ratio of raw materials and water consumption designed in this embodiment are as shown in Table 2.

[0020] Table 2 Embodiment 1 raw material ratio and water consumption

[0021] Example 1

Calcium-enriched liquid slag

Desulfurization gypsum

water

Mass / g

235

394

341

30

373

[0022] The specific implementation steps are as follows:

[0023] 1) Mixing: Weigh the raw materials according to the proportion and put them in the planetary mill, add water, grind for 2 hours, take out and pour the slurry into the mold, demould after molding, and obtain a block sample;

[0024] 2) Hydrothermal synthesis: put the above sample in a digital display constant temperature stirring circulation curing box that has been heated to a set temperature of 60°C, take it out and cool it after constant temperature curing for 10 hours;

[0025] 3) Calcination: After the cooled block sample is crushed, it is pla...

Embodiment 2

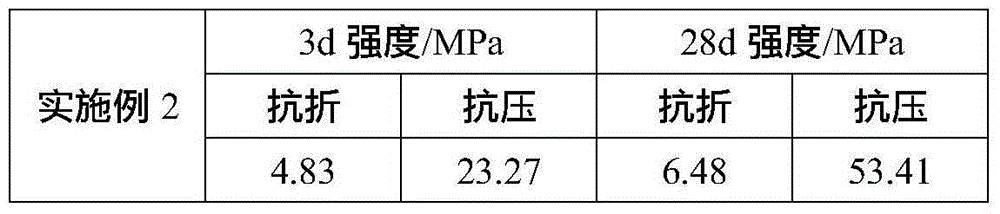

[0030] The ratio of raw materials and water consumption designed in this embodiment are as shown in Table 4.

[0031] Table 4 embodiment 2 raw material ratio and water consumption

[0032] Example 2

Calcium-enriched liquid slag

water

Mass / g

161

364

416

59

363

[0033] The specific implementation steps are as follows:

[0034] 1) Mixing: Weigh the raw materials according to the proportion and place them in a planetary mill, add water, grind for 5 hours, take out and pour the slurry into the mold, demould after molding, and obtain a block sample;

[0035] 2) Hydrothermal synthesis: put the above sample in a digital display constant temperature stirring circulation curing box that has been heated to a set temperature of 90°C, take it out and cool it after constant temperature curing for 6 hours;

[0036] 3) Calcination: After the cooled block sample is crushed, it is placed in a h...

Embodiment 3

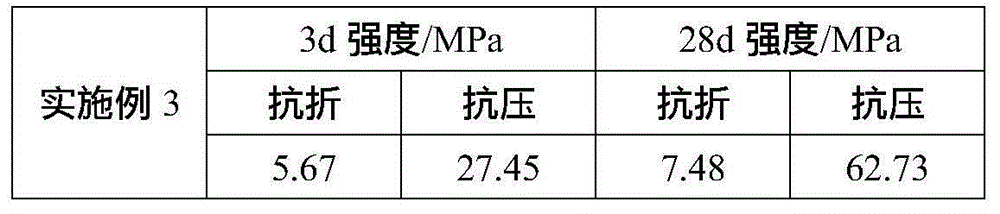

[0041] The ratio of raw materials and water consumption designed in this embodiment are as shown in Table 6.

[0042] Table 6 embodiment 3 raw material ratio and water consumption

[0043] Example 3

Carbide slag

Desulfurization gypsum

water

Mass / g

95

392

376

137

329

[0044] The specific implementation steps are as follows:

[0045] 1) Mixing: Weigh the raw materials according to the proportion and put them in the planetary mill, add water, grind for 7 hours, take out and pour the slurry into the mold, demould after molding, and obtain a block sample;

[0046] 2) Hydrothermal synthesis: Place the above sample in an autoclave that has been heated to a set temperature of 115°C, and take it out to cool after constant temperature curing for 4.5 hours;

[0047] 3) Calcination: After the cooled block sample is crushed, it is placed in a high-temperature furnace, calcined at 960°C for 70 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com