Belite-sulphoaluminate-ferrous aluminate cement and preparation method thereof

A ferroaluminate cement and sulfoaluminate technology, which is applied in cement production and other fields, can solve problems such as high energy consumption, achieve low energy consumption, solve environmental problems, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

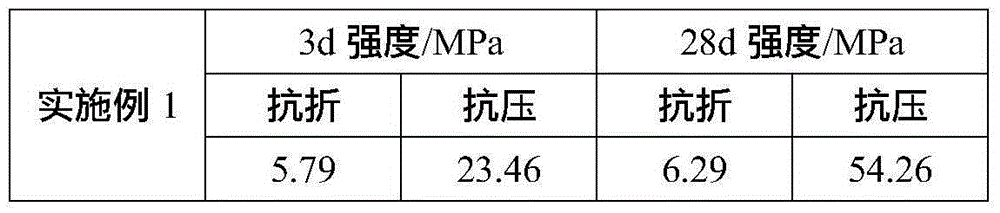

[0022] The ratio of raw materials and water consumption designed in this embodiment are as shown in Table 2.

[0023] Table 2: Raw material ratio and water consumption of embodiment 1

[0024] Example 1

Calcium-enriched liquid slag

Desulfurization gypsum

water

Mass / g

281

406

10

12

291

350

[0025] The specific implementation steps are as follows:

[0026] 1) Mixing: Weigh the raw materials according to the proportion and put them in the planetary mill, add water, grind for 2 hours, take out and pour the slurry into the mold, demould after molding, and obtain a block sample;

[0027] 2) Hydrothermal synthesis: put the above sample in a digital display constant temperature stirring circulation curing box that has been heated to a set temperature of 60°C, take it out and cool it after constant temperature curing for 9 hours;

[0028] 3) Calcination: After the cooled blo...

Embodiment 2

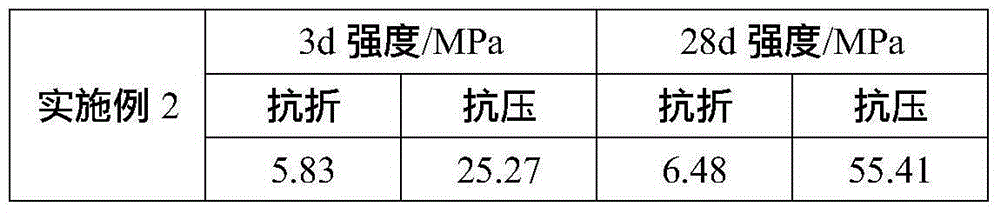

[0033] The ratio of raw materials and water consumption designed in this embodiment are as shown in Table 4.

[0034] Table 4: Raw material ratio and water consumption of embodiment 2

[0035] Example 2

Calcium-enriched liquid slag

sugar filter mud

Tailings bauxite

Desulfurization gypsum

water

Mass / g

241

490

9

10

250

338

[0036] The specific implementation steps are as follows:

[0037] 1) Mixing: Weigh the raw materials according to the proportion and put them in the planetary mill, add water, grind for 7 hours, take out and pour the slurry into the mold, demould after molding, and obtain a block sample;

[0038] 2) Hydrothermal synthesis: put the above sample in a digital display constant temperature stirring circulation curing box that has been heated to a set temperature of 90°C, take it out and cool it after constant temperature curing for 8 hours;

[0039] 3) Calcination: After the cooled ...

Embodiment 3

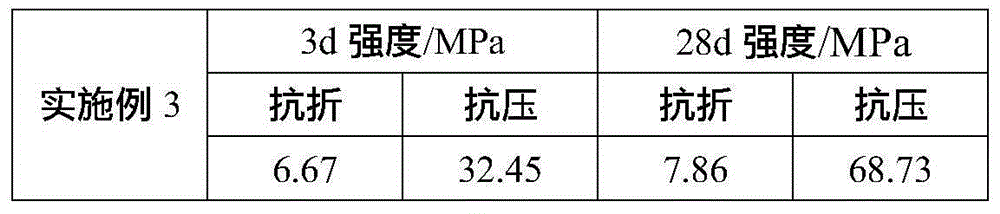

[0044] The ratio of raw materials and water consumption designed in this embodiment are as shown in Table 6.

[0045] Table 6: Raw material ratio and water consumption of embodiment 3

[0046] Example 3

sugar filter mud

Tailings bauxite

water

Mass / g

139

541

8

53

259

346

[0047] The specific implementation steps are as follows:

[0048] 1) Mixing: Weigh the raw materials according to the proportion and place them in a planetary mill, add water, grind for 10 hours, take out and pour the slurry into the mold, demould after molding, and obtain a block sample;

[0049] 2) Hydrothermal synthesis: Place the above sample in an autoclave that has been heated to a set temperature of 120°C, and take it out to cool after constant temperature curing for 3.5 hours;

[0050]3) Calcination: After the cooled block sample is crushed, it is placed in a high-temperature furnace, calcined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com