Low-energy-consumption and low-emission cement and preparation method and application thereof

A low-emission, low-energy-consumption technology, applied in cement production, clinker production, etc., can solve the problems of high energy consumption, large consumption of high-calcium raw materials, etc., and achieve the effects of reducing heat consumption, reducing energy, and saving coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, preparation of low energy consumption, low emission cement raw meal

[0045] The raw materials used to prepare the cement product of the present invention include: limestone, bauxite, gypsum and clay (or sandstone), all provided by Tangshan Polar Bear Building Materials Co., Ltd.

[0046] 1. Selection of raw materials

[0047] The above raw materials were pretreated respectively, including drying (105°C), crushing by a crusher, grinding and homogenizing by a ball mill, and samples were taken for full analysis of chemical components. The results are shown in Table 1:

[0048] The chemical composition (weight percent) of table 1 raw material

[0049] sample

L.O.I.

SiO 2

al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

SO 3

K 2 o

Na 2 o

limestone

42.72

0.78

0.31

0.08

/

54.77

0.67

/

0.04

0.05

14.68

4.78

74.91

...

Embodiment 2

[0061] Embodiment 2, low energy consumption, low discharge cement clinker calcining and the preparation of cement

[0062] According to the composition design of eight different clinker minerals in Table 2, eight groups of corresponding raw meals were prefabricated. For the raw materials used, refer to Table 1 in Example 1.

[0063] Table 2 mineral composition design (wt%)

[0064]

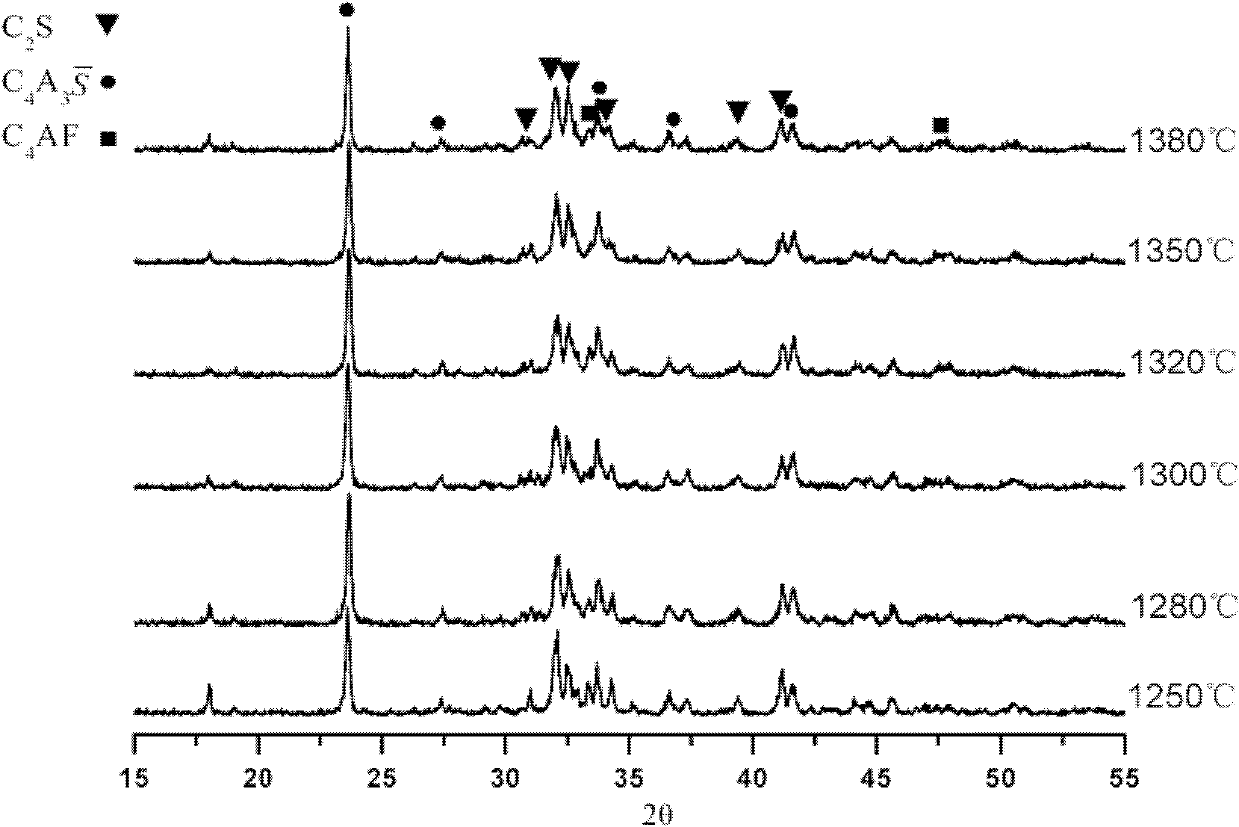

[0065] 1. Raw meal flammability test: the eight groups of samples in Table 2 are made into small samples with a diameter of 34mm, placed in a muffle furnace at 950°C (850-950°C is acceptable) and pre-fired at a constant temperature for 30min. Put it into silicon-molybdenum rod electric furnace at 6 temperatures: 1250°C, 1280°C, 1300°C, 1320°C, 1350°C and 1380°C for 30 minutes at constant temperature, then take out the clinker quickly and cool it to room temperature with a fan, and grind it to pass through an 80μm test sieve According to GB / T 176-2008 "Methods for Chemical Analysis of Cement", ...

Embodiment 3

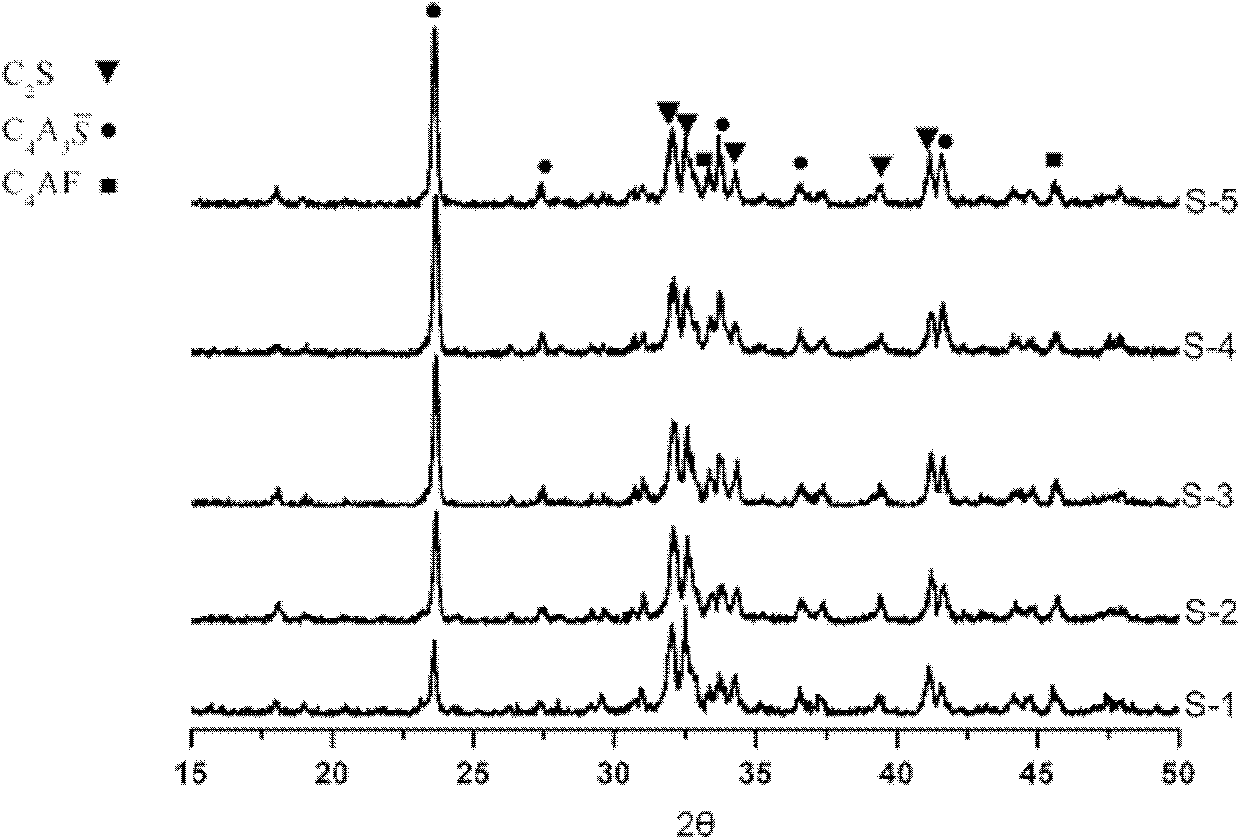

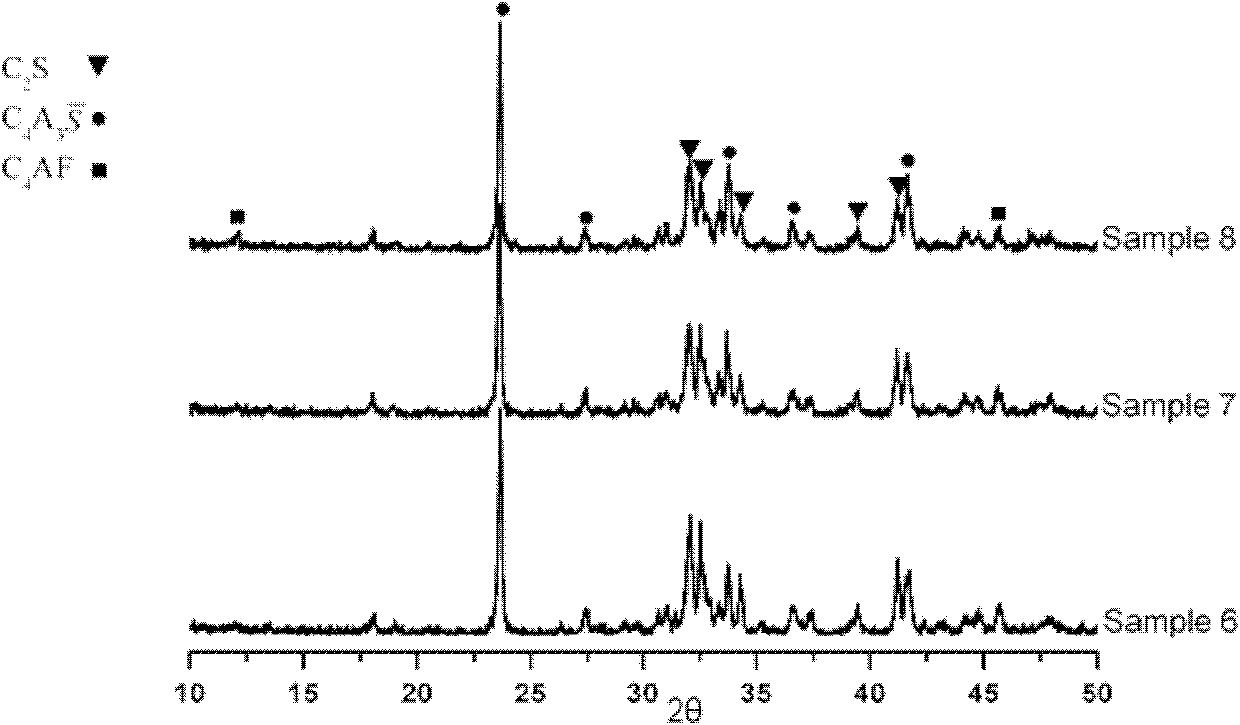

[0074] Embodiment 3, the optimization of low energy consumption, low emission cement clinker mineral components

[0075] The optimization experiments all adopt the following method to prepare cement samples: place the dried raw material test cake (the large sample in Example 1, φ118mm × 118mm) on a platinum sheet, and put it into a muffle furnace with a temperature of 950°C Pre-fire at a constant temperature for 45-70 minutes, then immediately transfer the pre-fired test cake together with the platinum sheet into a high-temperature furnace with a constant temperature of 1280°C-1300°C, and calcine at a constant temperature for 45-70 minutes to obtain cement clinker, which is mixed with 5% cement by weight Anhydrite becomes a cement sample.

[0076] 1. In clinker Determination of weight percentage

[0077] Ingredients according to the following design scheme: fixed C 4 AF content of 9%, C 2 S content varies in the range of 35-65%, Mineral contents are 22%, 27%, 32%, 37%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com