Refractory castable of nanocomposite oxide ceramic combining alumina-spinelle and preparation method thereof

A technology for refractory castables and oxide ceramics, applied in the field of refractory castables, can solve the problems of thermal shock resistance cracks and spalling damage, affecting the service life of the refining ladle, structural spalling and damage, etc. The effect of improving mechanical properties, slag corrosion resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

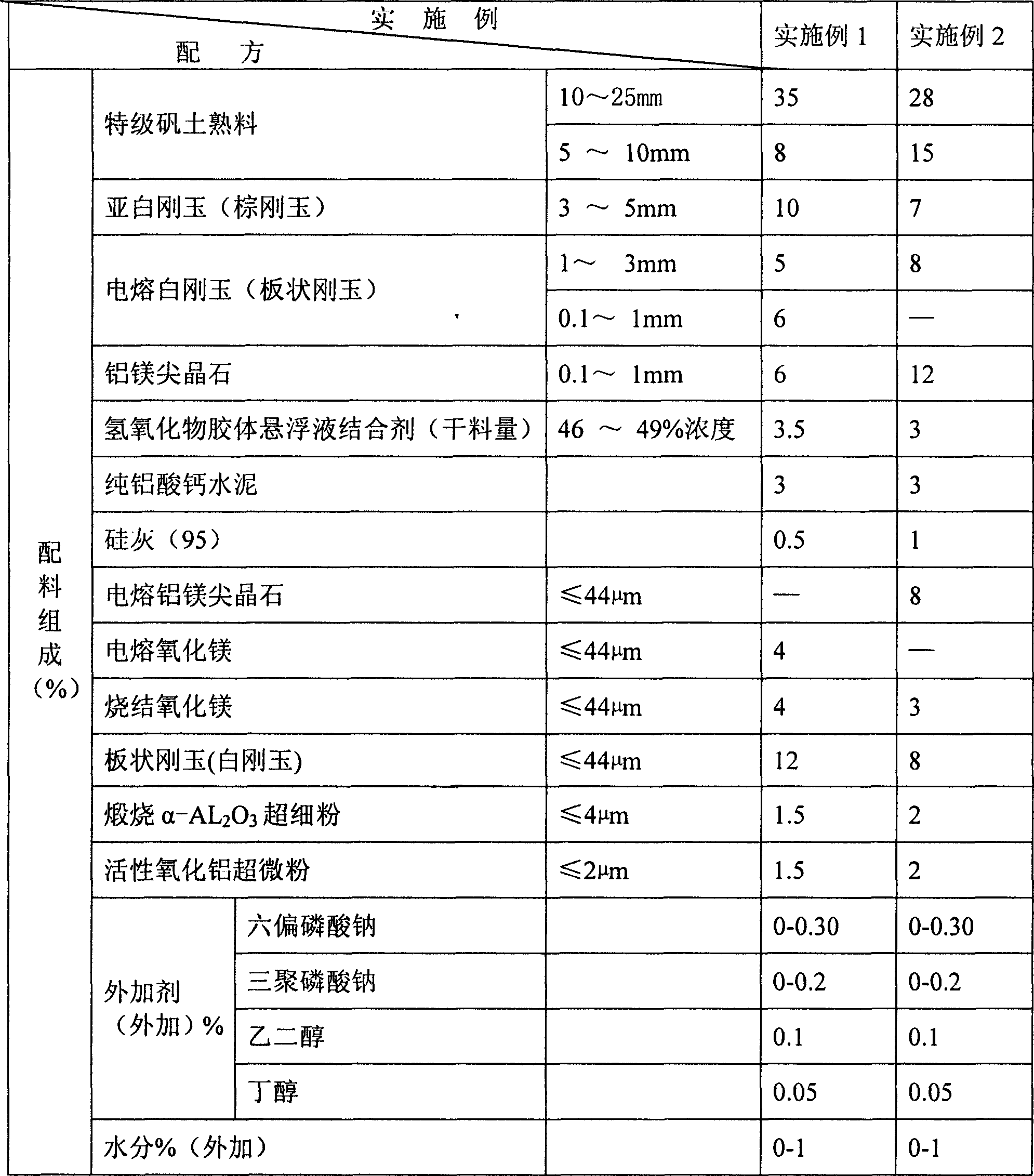

[0039] According to the reaction of the present invention listed in Example 1 of Table 1, the aluminum-spinel refractory castable formula is formed, the compound is added to the forced mixer and dry mixed for 1-2 minutes, and then the diluted and dispersed concentration is Add 46-49% nano hydroxide colloidal suspension binder directly into the mixture, then wet mix for 5 minutes, add 0-1% water according to the actual water demand of the mixture during the mixing process, and make the present invention Reaction to form nanocomposite oxide ceramics bonded to aluminum-spinel castables. The main properties of the castable in this example are shown in Table 2. Its biggest feature is its excellent resistance to slag erosion and slag penetration, and it is suitable for use in the cladding wall and impact zone of the refining furnace.

Embodiment 2

[0041] According to the embodiment 2 pre-synthesized aluminum-spinel refractory castable formula listed in Table 1 according to the present invention, the compound is added in a forced mixer for dry mixing for 1-2 minutes, and then the diluted and dispersed concentration is 46 -49% nano-hydroxide colloidal suspension binder is directly added to the mixture, and then wet mixed for 5 minutes. During the mixing process, 0-1% of water is added according to the actual moisture content of the mixture to make the pre-synthesis of the present invention Nanocomposite oxide ceramics bonded to aluminum-spinel refractory castables. The main properties of the castable in this example are listed in Table 2. Its biggest feature is that it has a stable structure, is not prone to cracks and peeling, and is suitable for use at the bottom of the LF refining furnace.

[0042] Table 1, the formula of embodiment 1 of the present invention and embodiment 2 refractory castable

[0043]

[0044] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com