Titanium-containing calcium aluminate-high alumina bauxite modified refractory material, as well as preparation method and application thereof

A technology of calcium aluminate titanate and high-alumina bauxite, which is applied in the field of refractory materials, can solve problems such as low cost, decreased strength, brittle fracture of drain bricks, etc., to reduce manufacturing costs, improve heat insulation performance, and enhance fire resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

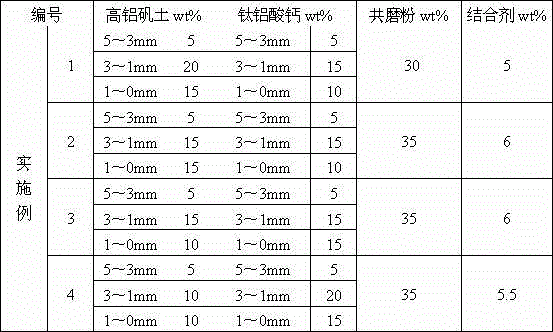

[0027] Example 1 The raw materials were weighed according to the formula in Table 1.

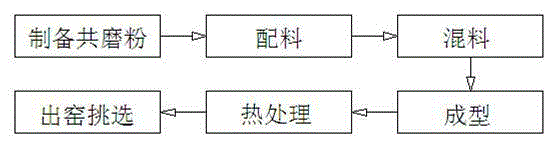

[0028] Such as figure 1 As shown, the preparation method of the calcium aluminate titanate-high alumina modified refractory material is specifically carried out according to the following steps:

[0029] 1) Preparation of co-grinding powder: According to 15 wt% calcium aluminate titanate fine powder, 8 wt% α-Al 2 o 3 Fine powder, 5 wt% graphite powder, 4 wt% silicon carbide fine powder, 2 wt% metal aluminum powder and 1 wt% high-temperature asphalt powder are uniformly mixed to make co-milled powder;

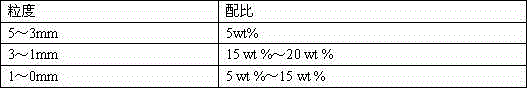

[0030] 2) Ingredients: 5-3mm high-bauxite 5wt%, 3-1mm high-bauxite 20wt%, 1-0mm high-bauxite 15wt%, 5-3mm calcium titanate 5wt%, 3-1mm titanium Calcium aluminate 15wt%, 1~0mm calcium aluminate titanate 10wt% ingredients;

[0031] 3) Mixing: Dry mix 40wt% calcium aluminate titanate and 30wt% high alumina bauxite particles with a wet mill for 2-3 minutes, then slowly add 3-6% phenolic resin...

Embodiment 2

[0035] Example 2 The preparation method is the same as in Example 1, and calcium aluminate titanate-high alumina modified refractory materials are prepared according to the formula shown in Table 1.

Embodiment 3

[0036] Example 3 The preparation method is the same as in Example 1, and calcium aluminate titanate-high alumina modified refractory materials are prepared according to the formula shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com