Cationic waterborne polyurethane resin and preparation method thereof

A water-based polyurethane and cationic technology, applied in the field of polyurethane, can solve the problems that water-based polyurethane emulsion cannot get rid of the dependence on petrochemical resources, complex process polyester diol, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

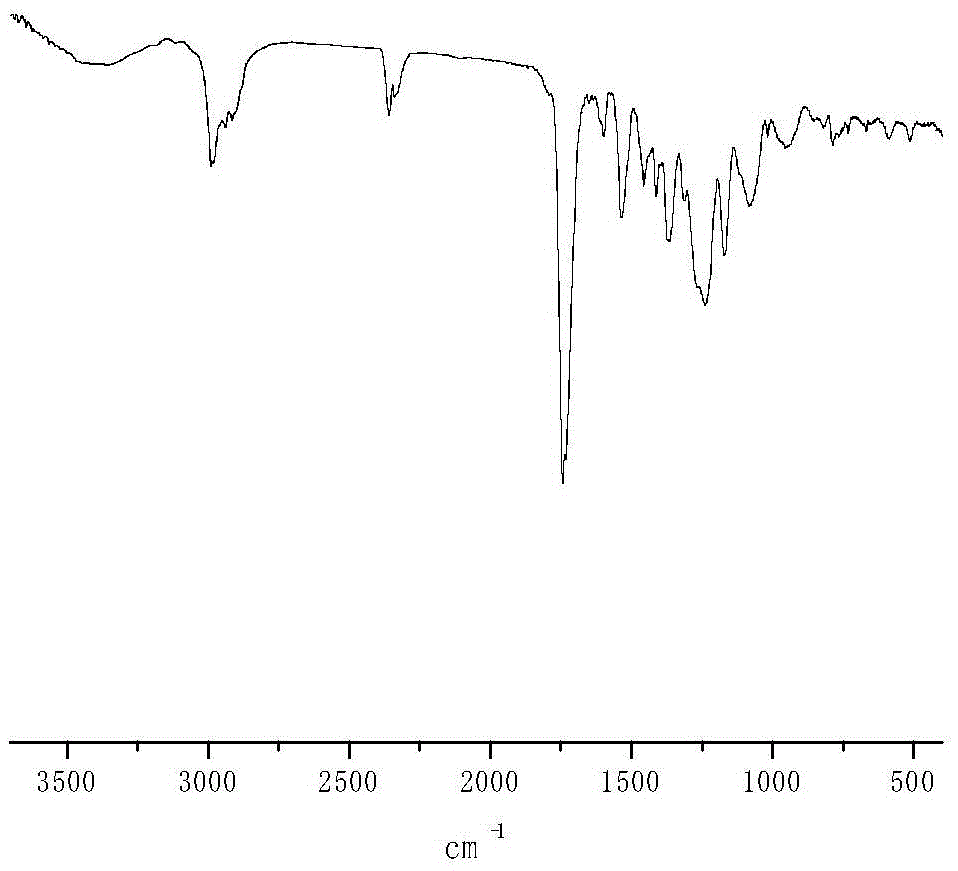

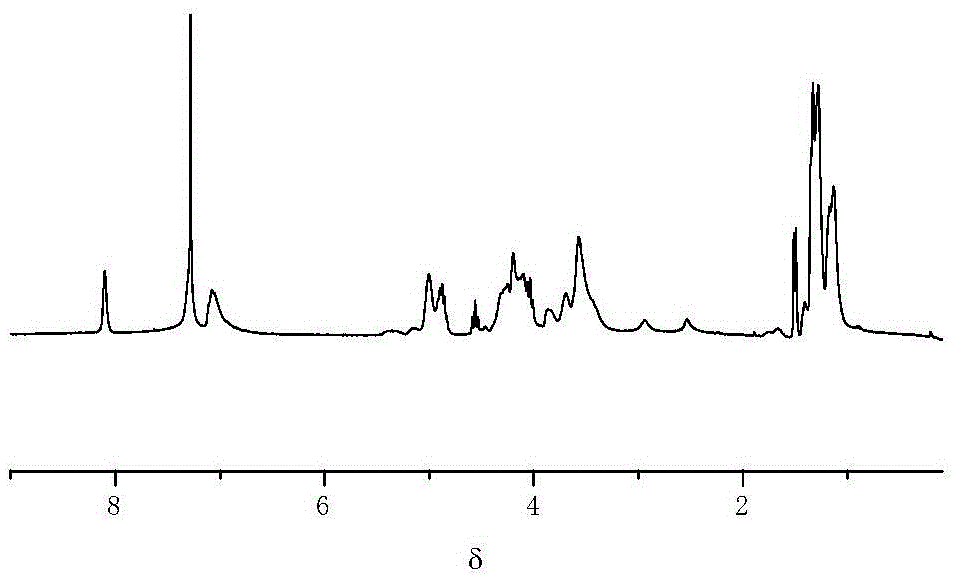

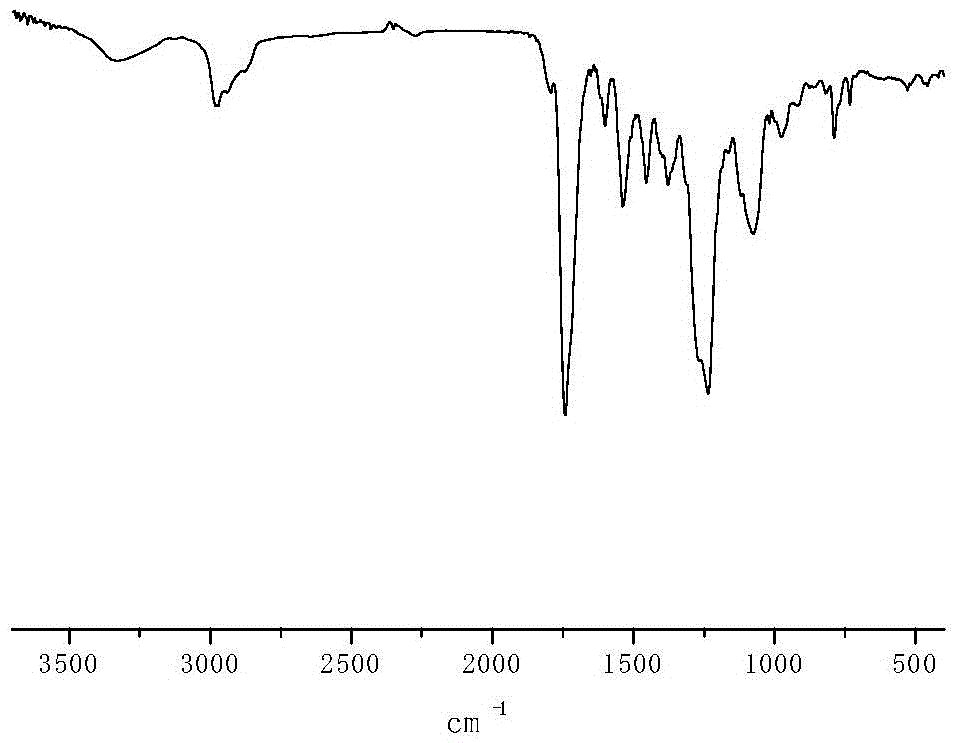

Image

Examples

preparation example Construction

[0046] Correspondingly, the present invention also provides a kind of preparation method of cationic waterborne polyurethane resin, comprises the following steps:

[0047] Step 1: under the protection of an inert gas, poly(carbonate-ether) glycol and diisocyanate are reacted in an organic solvent to obtain a first intermediate;

[0048] Step 2: reacting the first intermediate obtained in step 1 with the hydrophilic chain extender under the action of a catalyst to obtain the second intermediate;

[0049] Step 3: react the second intermediate obtained in Step 2 with butanediol, add acid for neutralization, add deionized water to emulsify and evaporate the solvent to obtain a cationic water-based polyurethane resin.

[0050] According to the present invention, under the protection of an inert gas, poly(carbonate-ether) glycol and diisocyanate are reacted in an organic solvent to obtain the first intermediate; the present invention has no special restrictions on the inert gas, pre...

Embodiment 1

[0063] According to the method disclosed in Example 11 of patent 201210086834.X, a poly(carbonate-ether) glycol with a number average molecular weight of 1500 Daltons was prepared.

[0064] Add 100 grams of prepared poly(carbonate-ether) glycol with a molecular weight of 1500 Daltons into the three-necked flask, heat to 110°C, dehydrate at -0.98MPa for 1 hour, cool down to 75°C, and protect it under nitrogen , add 170 grams of methyl ethyl ketone and 57 grams of xylene methane diisocyanate, react for 2 hours, then cool down to 30 degrees, dropwise add 0.0015 grams of dibutyltin dilaurate catalyst, add 8 grams of N-methyldiethanolamine in three batches, add After completion, react for 1 hour, then heat up to 70°C, add 3.8 grams of butanediol, react for 2 hours, add glacial acetic acid to neutralize the pH to 7, then add 140 grams of deionized water, stir at 1200 rpm for 1 hour, and remove butanone under reduced pressure , to obtain a cationic waterborne polyurethane resin. The...

Embodiment 2

[0069] According to the method disclosed in Example 8 of the patent 201210086834.X, a poly(carbonate-ether) glycol with a number average molecular weight of 2800 Daltons was prepared.

[0070] Add 180 grams of prepared poly(carbonate-ether) glycol with a molecular weight of 2800 Daltons into the three-necked flask, heat to 100°C, dehydrate at -0.98MPa for 2 hours, cool down to 72°C, and protect it under nitrogen , add 250 grams of butanone and 40 grams of toluene diisocyanate, react for 1.5 hours, then cool down to 30 degrees, add 0.0016 grams of dibutyltin dilaurate catalyst dropwise, add 8.5 grams of N-methyldiethanolamine in three batches, after the addition is complete React for 1 hour, then heat up to 65°C, add 4.3 grams of butanediol, react for 2 hours, add concentrated hydrochloric acid to neutralize the pH to 7, then add 250 grams of deionized water, stir at 1500 rpm for 2 hours, and remove butanone under reduced pressure, that is A cationic waterborne polyurethane res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com