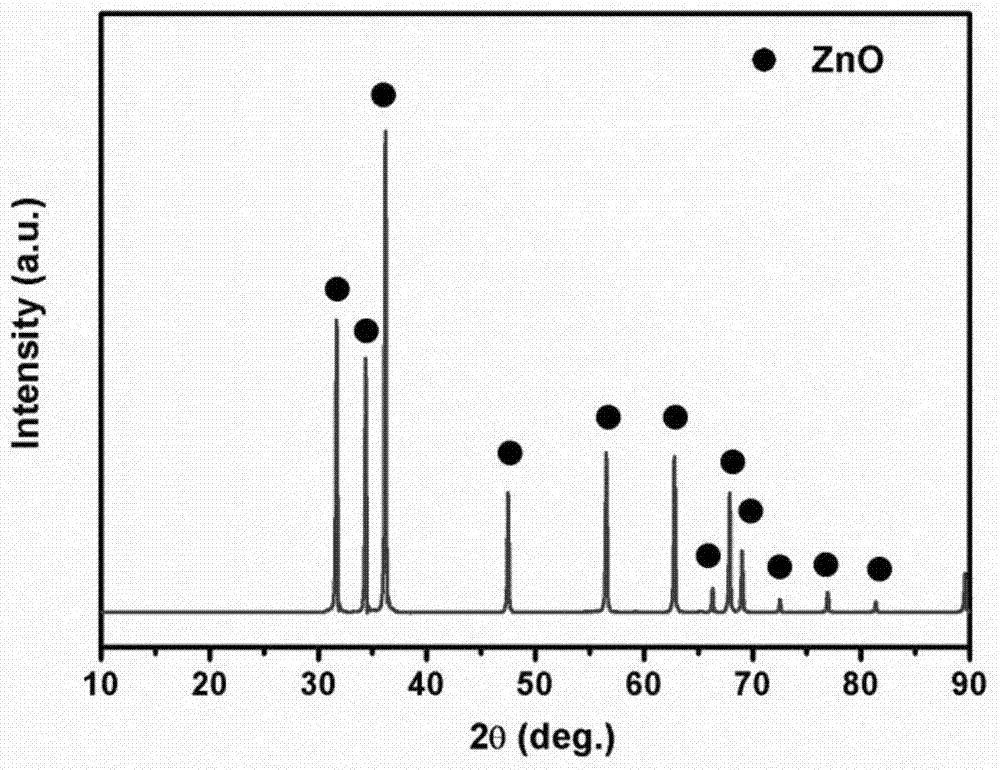

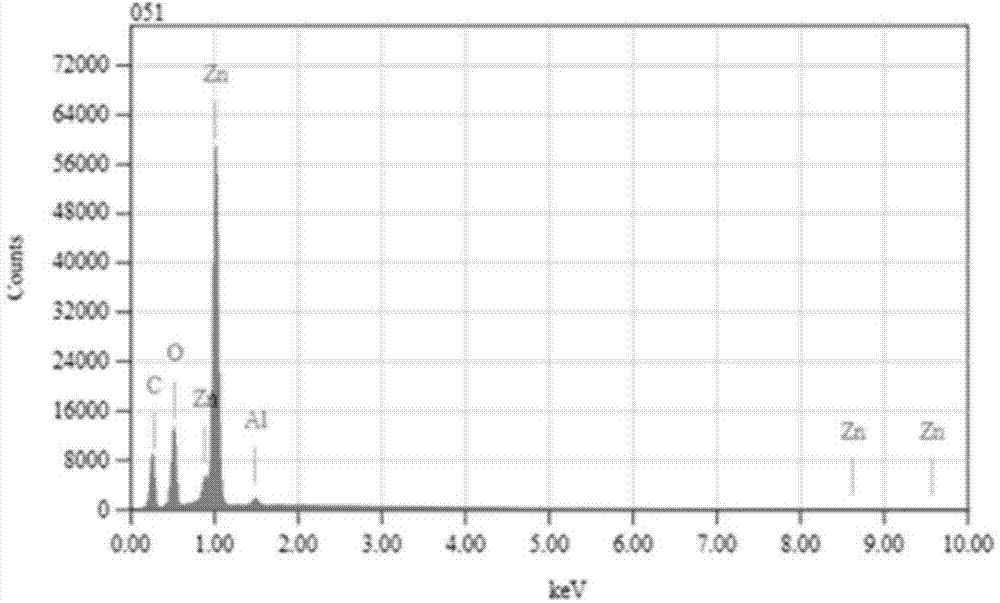

Preparation method of aluminum-doped zinc oxide nano powder

A technology of aluminum-doped zinc oxide and nano-powders, which is applied in chemical instruments and methods, zinc oxide/zinc hydroxide, and other chemical processes, and can solve the problems of high cost, complex process of aluminum-doped zinc oxide nano-powders, Problems such as particle size and dispersibility are not easy to control, so as to achieve the effect of low cost, preventing powder agglomeration and growth, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

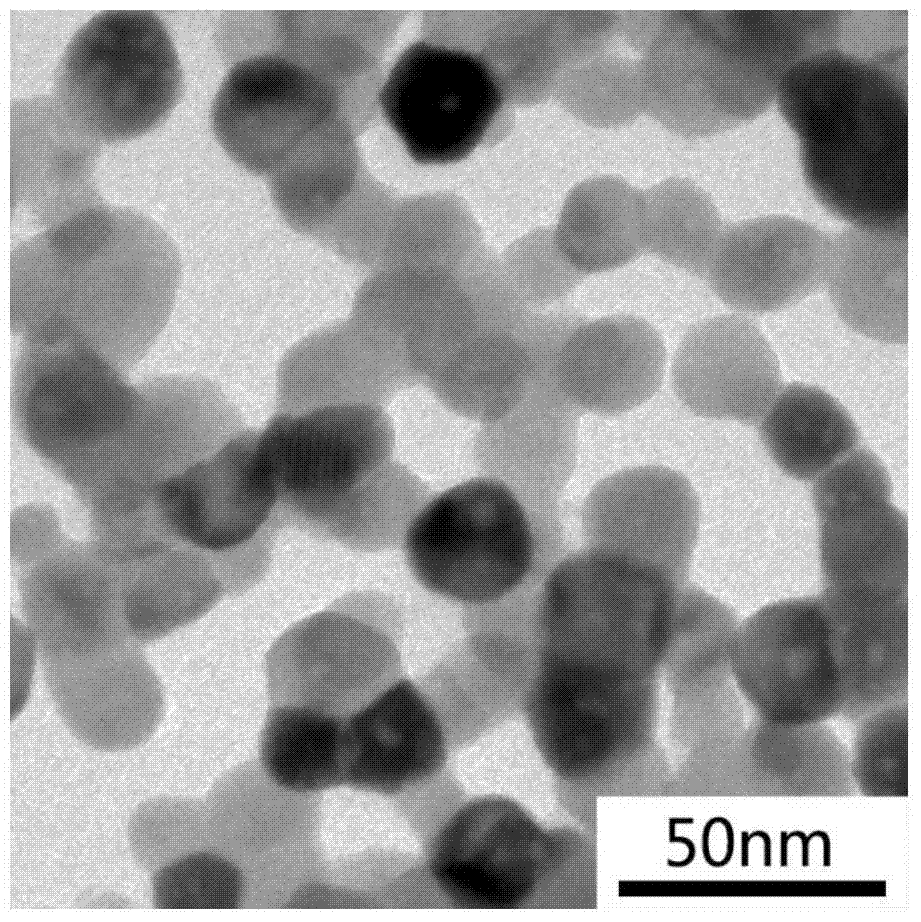

[0025] Weigh 0.1 mole of zinc nitrate, 0.002 mole of aluminum nitrate, 0.4 mole of urea, and 0.03 mole of glucose and dissolve them in distilled water to prepare a solution, and place the solution on a temperature-controllable electric furnace for heating. The solution decomposes after volatilization and concentration to obtain precursor powder. The precursor powder was reacted in a furnace at 700° C. and air atmosphere for 1 hour to obtain aluminum-doped zinc oxide nanopowder with mesoporous structure. The particle size of the obtained powder is 30-60 nm, and it takes 15 minutes for the adsorbent with a concentration of 1 g / L to degrade 20 ppm of methyl orange pollutants.

Embodiment 2

[0027] Weigh 0.1 mol of zinc nitrate, 0.004 mol of aluminum nitrate, 0.42 mol of urea, and 0.025 mol of glucose and dissolve them in distilled water to prepare a solution, and heat the solution on a temperature-controllable electric furnace. The solution decomposes after volatilization and concentration to obtain precursor powder. The precursor powder was reacted in a furnace at 700° C. and air atmosphere for 1 hour to obtain aluminum-doped zinc oxide nanopowder with mesoporous structure. The particle size of the obtained powder is 20-50 nm, and it takes 5 minutes for the adsorbent with a concentration of 1 g / L to degrade 20 ppm of methyl orange pollutants.

Embodiment 3

[0029] Weigh 0.1 mol of zinc nitrate, 0.008 mol of aluminum nitrate, 0.43 mol of urea, and 0.03 mol of glucose and dissolve them in distilled water to prepare a solution, and heat the solution on a temperature-controllable electric furnace. The solution decomposes after volatilization and concentration to obtain precursor powder. The precursor powder was reacted in a furnace at 500° C. and air atmosphere for 1 hour to obtain aluminum-doped zinc oxide nanopowder with mesoporous structure. The particle size of the obtained powder is 15-35 nm, and it takes 3 minutes for the adsorbent with a concentration of 1 g / L to degrade 20 ppm of methyl orange pollutants.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com