Comprehensive utilization method of solvent and by-product in preparation of HFPO by oxygen oxidation method

A technology for oxygen oxidation and by-products, applied in chemical instruments and methods, amino compound preparation, organic compound preparation, etc., can solve the problems of unavailable systems, equipment corrosion, and inability to obtain high-purity solvents, etc., to reduce equipment costs and The cost of waste liquid treatment, avoiding the accumulation of by-products, and the effect of simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Oxygen oxidation method prepares the comprehensive utilization method of solvent and by-product in HFPO, and the steps are as follows:

[0050] (1) Separation: Oxygen is used as oxidant, hexafluoropropylene is used as raw material, HFPO is prepared by oxygen oxidation method, DY-01 is used as solvent, and after 50 kettles of intermittent reaction, the fluorocarbon to be purified containing acyl fluoride by-products is taken out Solvent, the by-product was found to be mainly CF 3 O(CF(CF 3 ) CF 2 O) 2 CF 2 COF and CF 3 CF 2 O(CF 2 CF 2 O) 2 CF(CF 3 ) COF, the total content is 26wt%.

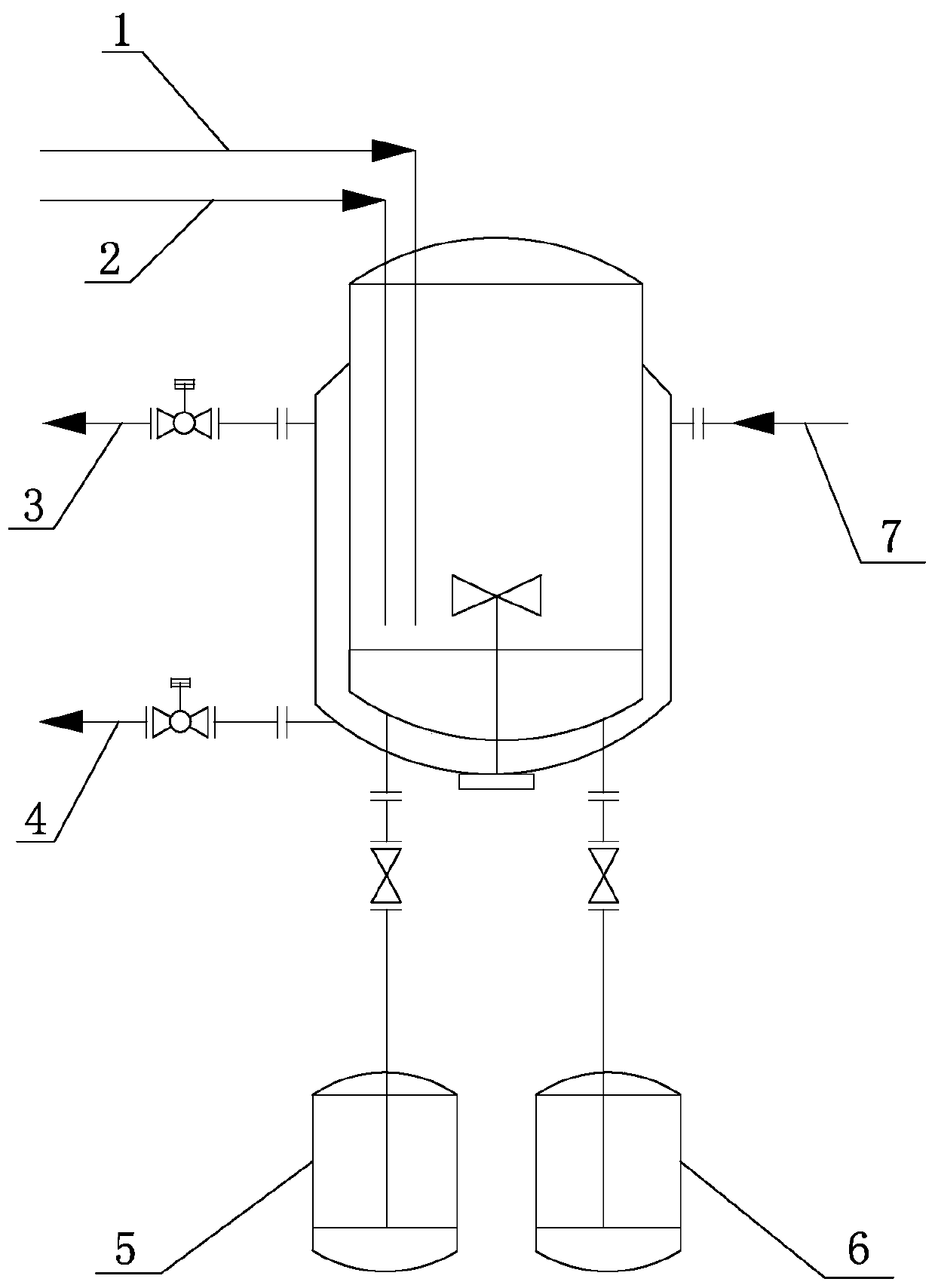

[0051] (2) Alcohol washing: mix the fluorocarbon solvent to be purified with absolute ethanol in a volume ratio of 1:1, figure 1 Mix in the washing device shown, turn on the stirring, and pass in circulating water to control the temperature of the washing tank below 40°C. After stirring for 6 hours, start to stand still. After standing for 2 hours, the liquid separation is comple...

Embodiment 2

[0060] (1) Separation: Oxygen is used as oxidant, hexafluoropropylene is used as raw material, and HFPO is prepared by oxygen oxidation method, and DY-02 is used as solvent. After 30 kettles of intermittent reaction, the fluorocarbon to be purified containing acyl fluoride by-products is taken out Solvent, the by-product was found to be mainly CF 3 CF 2 CF 2 O(CF 2 CF 2 O) 2 CF(CF 3 ) COF, the total content is 19wt%.

[0061] (2) Alcohol washing: the fluorocarbon solvent to be purified and absolute ethanol in a volume ratio of 2:1, in figure 1 Mix in the washing device shown, turn on the stirring, and pass in circulating water to control the temperature of the washing tank below 40°C. After stirring for 6 hours, start to stand still. After standing for 2 hours, the liquid separation is completed, and the fluorocarbon solvent after alcohol washing and Hydrogen fluoride ethanol solution;

[0062] The hydrogen fluoride content in the hydrogen fluoride ethanol solution is ...

Embodiment 3

[0070] (1) Separation: Oxygen is used as oxidant, hexafluoropropylene is used as raw material, HFPO is prepared by oxygen oxidation method, DY-03 is used as solvent, and after 30 kettles of intermittent reaction, the fluorocarbon to be purified containing acyl fluoride by-products is taken out Solvent, the by-product was found to be mainly CF 3 OCF 2 CF 2 OCF (CF 3 ) CF 2 OCF (CF 3 ) COF, the total content is 20wt%.

[0071] (2) Alcohol washing: mix the fluorocarbon solvent to be purified with anhydrous propanol at a volume ratio of 0.5:1, in figure 1 Mix in the washing device shown, turn on the stirring, and pass in circulating water to control the temperature of the washing tank below 40°C. After stirring for 5 hours, start to stand still. After standing for 2 hours, the liquid separation is completed, and the fluorocarbon solvent after alcohol washing and Hydrogen fluoride propanol solution;

[0072] The hydrogen fluoride content in the hydrogen fluoride-propanol sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com