Wet treatment method of copper smelting acid-making acid mud

A technology for wet processing and copper smelting, applied in the fields of non-ferrous smelting and environmental treatment, can solve the problems of incomplete separation of acid sludge-related elements, and achieve the effects of simple operation, easy control of process parameters and good operating environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

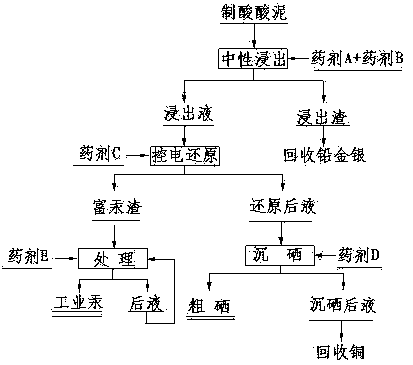

[0021] A kind of wet treatment method of copper smelting acid mud, such as figure 1 As shown, the specific processing steps are as follows:

[0022] Take 1000g of acid mud and analyze its main chemical composition: Au: 28.5g / t, Ag: 510.6g / t, Pb: 56.53%, Cu: 2.79%, Se: 3.99%, Hg: 0.921%. Add the acid mud to 1000mL of water, the pH of the solution after mixing is about 4.5, heat up to 75°C, add 73.6g of sodium chlorate and 88.0g of sodium nitrate, react for 3 hours, filter to obtain leaching residue and leaching liquid, and recover gold from the leaching residue Silver lead; add 18.0g of copper powder to the leaching solution, react at 20°C for 3 hours, and the end point potential is 415mv to obtain 11.0g of mercury-rich slag and reduced liquid. The mercury-rich slag contains 84.2% mercury, 0.51% copper, 0.12% selenium, rich Mercury slag is mixed with water according to the liquid-solid mass ratio of 1:2 to obtain mercury-rich slag slurry. Add 15 g of hydrazine hydrate to the m...

Embodiment 2

[0024] A kind of wet processing method of copper smelting acid mud, its specific processing steps are as follows:

[0025] Take 1000g of acid mud and analyze its main chemical composition as follows: Au: 7g / t, Ag: 588g / t, Pb: 58.76%, Cu: 0.66%, Se: 1.85%, Hg: 0.453%. Add the acid mud to 1000mL of water, the pH of the solution after mixing is about 4.0, raise the temperature to 85°C, add 36.8g of sodium chlorate and 34.5g of sodium chloride, react for 2 hours, filter to obtain leaching residue and leaching liquid, and recover the leaching residue Gold, silver and lead; 6.5g of copper powder was added to the leaching solution, reacted at 30°C for 2 hours, and the terminal potential was 385mv to obtain 5.2g of mercury-rich slag and reduced liquid. The mercury-rich slag contained 83.9% of mercury, 0.45% of copper, and 0.26% of selenium. Mercury-rich slag is mixed with water according to the liquid-solid mass ratio of 1:2 to obtain mercury-rich slag slurry. Add 10 g of hydrazine hy...

Embodiment 3

[0027] A kind of wet processing method of copper smelting acid mud, its specific processing steps are as follows:

[0028] Take 1000g of acid mud and analyze its main chemical composition as follows: Au: 14.6g / t, Ag: 495.6g / t, Pb: 60.74%, Cu: 0.25%, Se: 2.87%, Hg: 0.676%. Add the acid mud to 1000mL of water, the pH of the solution after mixing is about 4.5, raise the temperature to 80°C, add 42.6g of sodium peroxide and 53.2g of sodium chloride, react for 2 hours, filter to obtain leaching residue and leaching liquid, and recover the leaching residue Gold, silver and lead; add 10.0g of copper powder to the leaching solution, react at 30°C for 2 hours, and the terminal potential is 385mv to obtain 7.9g of mercury-rich slag and reduced liquid. The mercury-rich slag contains 84.3% of mercury, 0.38% of copper, and 0.13% of selenium. Mercury-rich slag is mixed with water according to the liquid-solid mass ratio of 1:2 to obtain mercury-rich slag slurry. Add 12 g of hydrazine hydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com