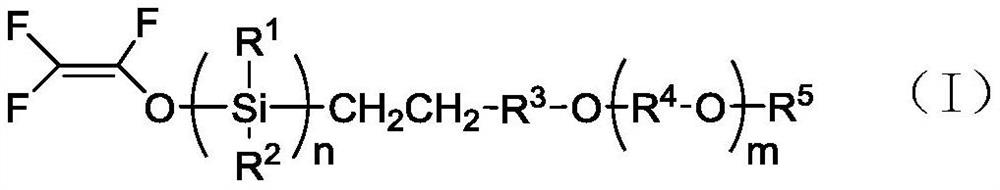

Modified polytrifluorochloroethylene and preparation method thereof

A technology of polychlorotrifluoroethylene and chlorotrifluoroethylene, which is applied in the field of modified polychlorotrifluoroethylene, can solve the problems of small melt index, high melt viscosity, and low elongation at break, and meet the processing and application requirements , the effect of large melt index and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

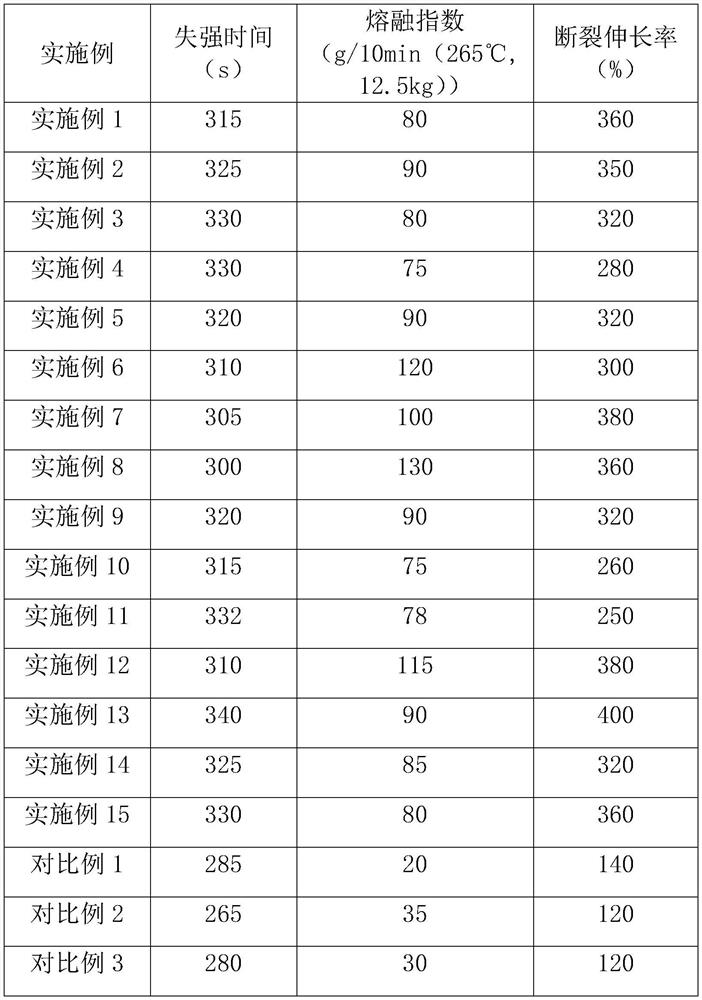

Embodiment 1

[0051] Add 56.4g of chlorotrifluoroethylene, 3.6g of modified monomer fluorosiloxane compound in 5L reactor 3L deionized water, 4.5g sodium perfluorooctanoate and 3.0g NH 4 HCO 3 . The temperature of the reactor was raised to 40° C., the pressure of the reactor was 0.5 MPa, and 3.0 g of bis(trichloroacetyl) peroxide was added to initiate the reaction. Subsequently, the above-mentioned modified monomer was continuously added at a rate of 3.4 g / h, and chlorotrifluoroethylene was continuously added at a rate of 53.6 g / h to maintain the pressure of the reactor at 0.5 MPa. During the reaction process, a total of 1200 g of polymerization monomers were added to the reactor, and the total reaction time was 20 h. The polymerized emulsion was demulsified, washed and dried to obtain 1050 g of modified polychlorotrifluoroethylene.

[0052] After testing: the modified polychlorotrifluoroethylene contains 6wt% modified monomers, the strength loss time is 315s, the melt index is 80g / 10m...

Embodiment 2

[0054] Add 115.8g of chlorotrifluoroethylene, 4.2g of modified monomer fluorosiloxane compound in 5L reactor 3L of deionized water, 4.5g of ammonium perfluorooctanoate and 3.0g of sodium dihydrogen phosphate. The temperature of the reaction kettle was raised to 35° C., and the pressure of the reaction kettle was 0.8 MPa, and 3.0 g of tert-butyl peroxybenzoate was added to initiate the reaction. Subsequently, the above-mentioned modified monomer was continuously added at a rate of 3.2 g / h, and chlorotrifluoroethylene was continuously added at a rate of 86.8 g / h to maintain the pressure of the reactor at 0.8 MPa. During the reaction process, a total of 1200 g of polymerization monomers were added to the reactor, and the total reaction time was 12 hours. The polymerized emulsion was demulsified, washed and dried to obtain 1100 g of modified polychlorotrifluoroethylene.

[0055] After testing: the modified polychlorotrifluoroethylene contains 6wt% modified monomers, the strengt...

Embodiment 3

[0057] Add 117.1g of chlorotrifluoroethylene, 2.9g of modified monomer fluorosiloxane compound in 5L reactor 3L of deionized water, 4.5g of potassium perfluorooctanoate and 3.0g of sodium tetraborate. The temperature of the reactor was raised to 50° C., the pressure of the reactor was 1.2 MPa, and 3.0 g of diisopropyl peroxydicarbonate was added to initiate the reaction. Subsequently, the above-mentioned modified monomer was continuously added at a rate of 3.2 g / h, and chlorotrifluoroethylene was continuously added at a rate of 131.8 g / h to maintain the pressure of the reactor at 1.2 MPa. During the reaction, a total of 1200 g of polymerization monomers were added to the reactor, and the total reaction time was 8 hours. The polymerized emulsion was demulsified, washed and dried to obtain 1090 g of modified polychlorotrifluoroethylene.

[0058] After testing: the modified polychlorotrifluoroethylene contains 6wt% modified monomers, the strength loss time is 330s, the melt in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com