High-strength PVC blow molding die head

A blow molding die, high-strength technology, applied in the field of blow molding equipment, can solve the problems of poor fluidity, poor thermal stability, low strength of PVC film, etc., and achieve the effect of improving its own strength, uniform thickness and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

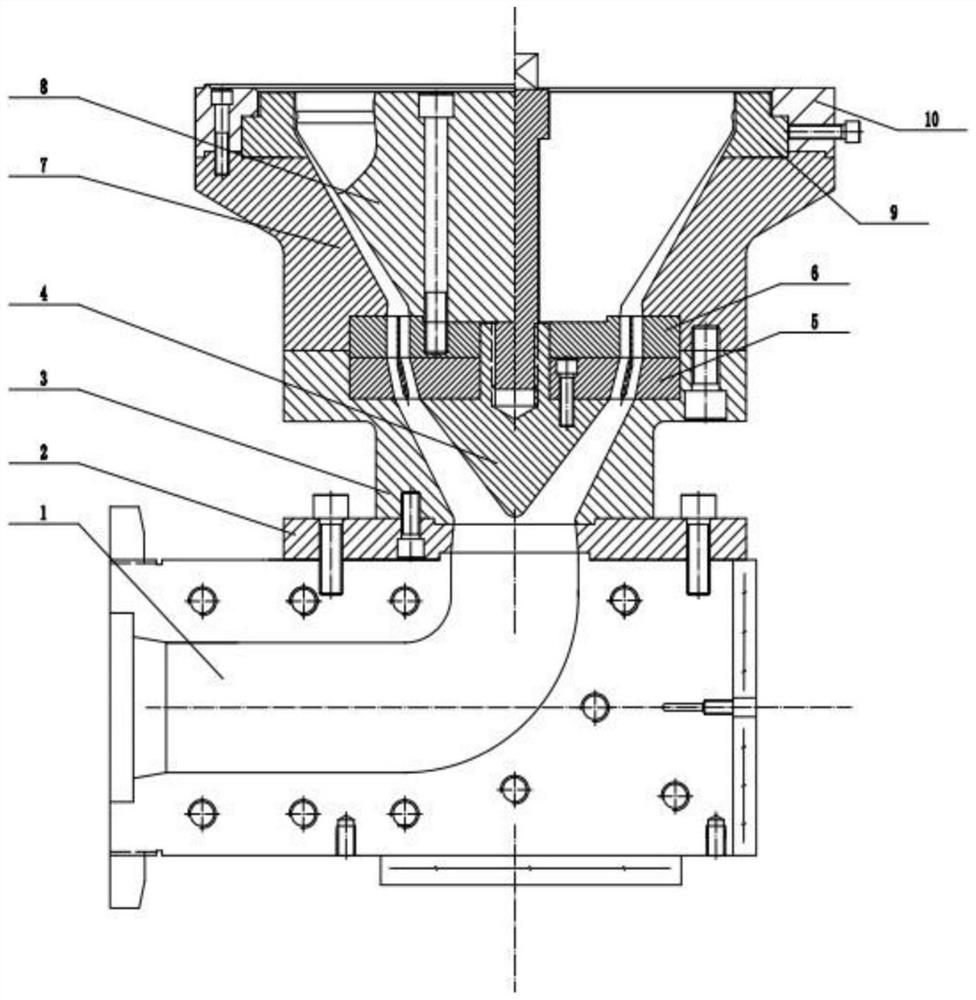

[0012] A high-strength PVC blow molding die head of the present invention, the overall structure schematic diagram is as follows figure 1 As shown, it includes feeding device 1, runner flange 2, outer mold lower body 3, splitter cone 4, splitter comb 5, weaving splitter 6, outer mold upper body 7, mold core 8, adjustment ring 9 and pressure ring 10 and other parts, each part shall be fastened and connected by bolts in sequence.

[0013] The molten and plasticized PVC melt enters the main channel between the lower body of the outer mold 3 and the splitter cone 4 through the feeding device 1. The lower body of the outer mold and the feeding device are connected by a bolt flange 2, and the function of the splitter cone 4 is to connect the feeding device The conveyed cylindrical melt is transformed into annular fluid, and the diverter cone 4 is connected with the diverter comb 5, and a plurality of bolt bayonets are arranged between the diverter comb 5 and the diverter cone 4 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com