Preparation method of polyamide 6 elastomer, and polyamide 6 elastomer prepared by preparation method

A polyamide and elastomer technology, which is applied in the field of new polymer material preparation, can solve the problems of industrialization difficulties, does not involve lactam type and aminocarboxylic acid type polyamide elastomer resins, etc., and achieves high melt strength and wide processing. range, and the effect of improving responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

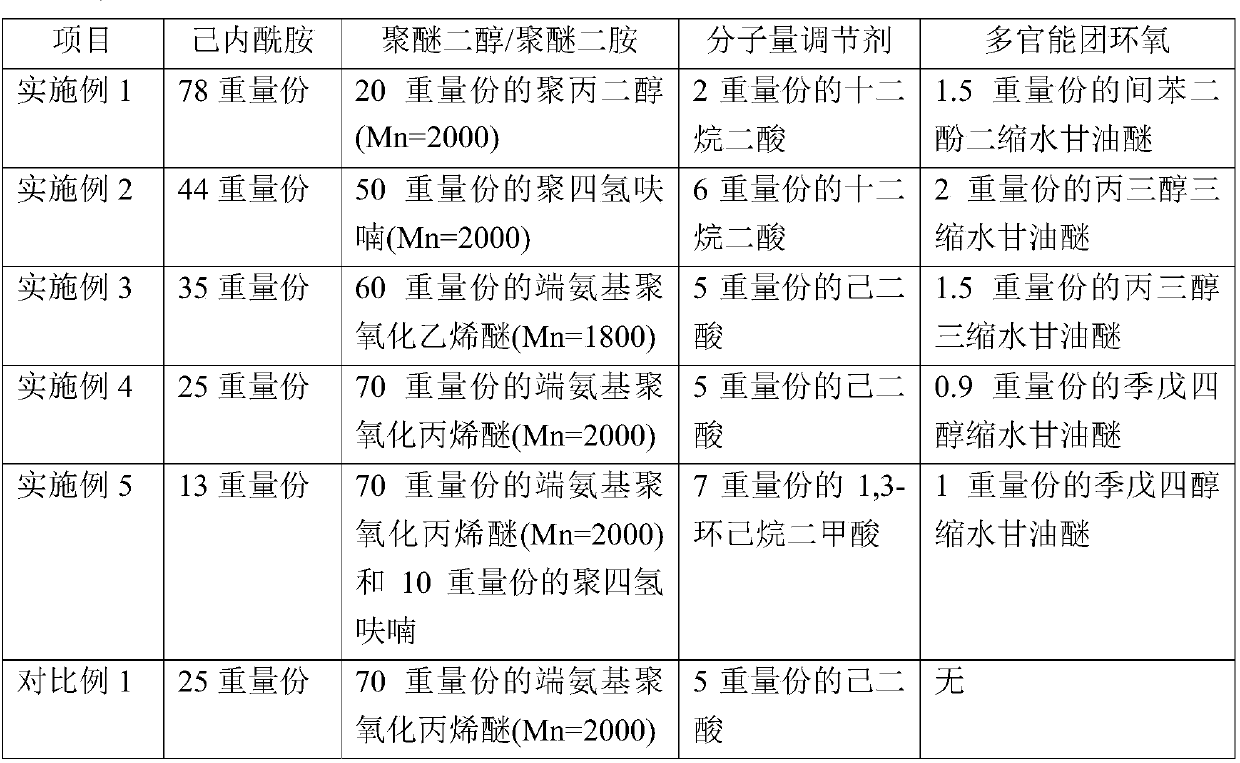

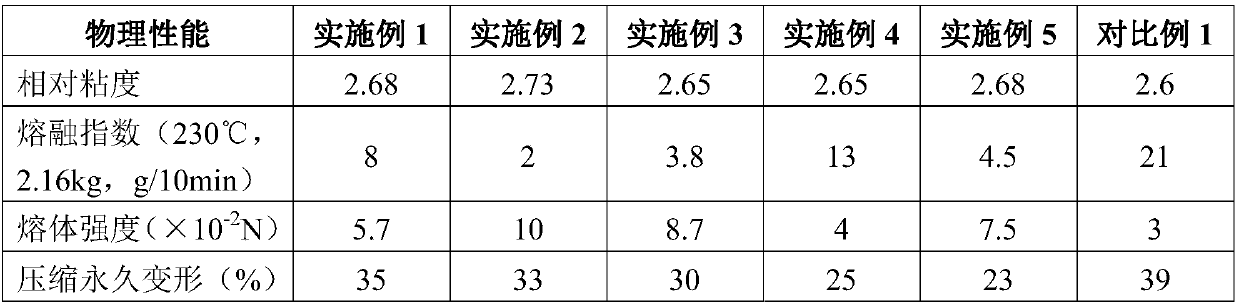

Examples

Embodiment 1

[0044] Add 3110g of caprolactam, 110g of distilled water, 800g of polypropylene glycol (Mn=2000), 92g of dodecanedioic acid, and 60g of phosphoric acid in a 10L polymerization kettle, heat up to 200°C under nitrogen protection, and react for 3 hours under mechanical stirring at 300rpm; then At 260°C, react with 300rpm mechanical stirring for 5 hours; add 60g of resorcinol diglycidyl ether at 270°C, vacuum to 100Pa and continue to react with 100rpm mechanical stirring for 3 hours, then cast, pull Stripping, granulation, and finally putting the granulated elastomer resin into an extraction kettle, stirring and extracting with distilled water at 90-100°C for 8 hours, centrifugal dehydration, and drying to obtain the polyamide 6 elastomer.

Embodiment 2

[0046] Add 1770g caprolactam, 70g distilled water, 2000g polytetrahydrofuran (Mn=2000), 230g dodecanedioic acid, 53g phosphoric acid into a 10L polymerization kettle, heat up to 190°C under nitrogen protection, and react for 3 hours under mechanical stirring at 300rpm; then React at 250°C for 6 hours with mechanical stirring at 300rpm; add 80g of glycerol triglycidyl ether at 260°C, vacuum to 100Pa and continue to react with mechanical stirring at 100rpm for 3 hours, then cast belts and pull bars , granulation, and finally put the granulated elastomer resin into the extraction kettle, stir and extract with distilled water at 90-100° C. for 8 hours, centrifugally dehydrate, and dry to obtain the polyamide 6 elastomer.

Embodiment 3

[0048] Add 1410g of caprolactam, 55g of distilled water, 2400g of amino-terminated polyoxyethylene ether (Mn=1800), 195g of adipic acid, and 30g of phosphoric acid into a 10L polymerization kettle, raise the temperature to 180°C under nitrogen protection, and react for 2 hours under mechanical stirring at 300rpm Then, at 240°C, react with 300rpm mechanical stirring for 5 hours; after adding 60g of glycerol triglycidyl ether at 260°C, vacuumize to 100Pa and continue to react with 200rpm mechanical stirring for 2 hours, then cast belt, Stranding, granulation, and finally putting the granulated elastomer resin into an extraction kettle, stirring and extracting with distilled water at 90-100°C for 8 hours, centrifugal dehydration, and drying to obtain the polyamide 6 elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com