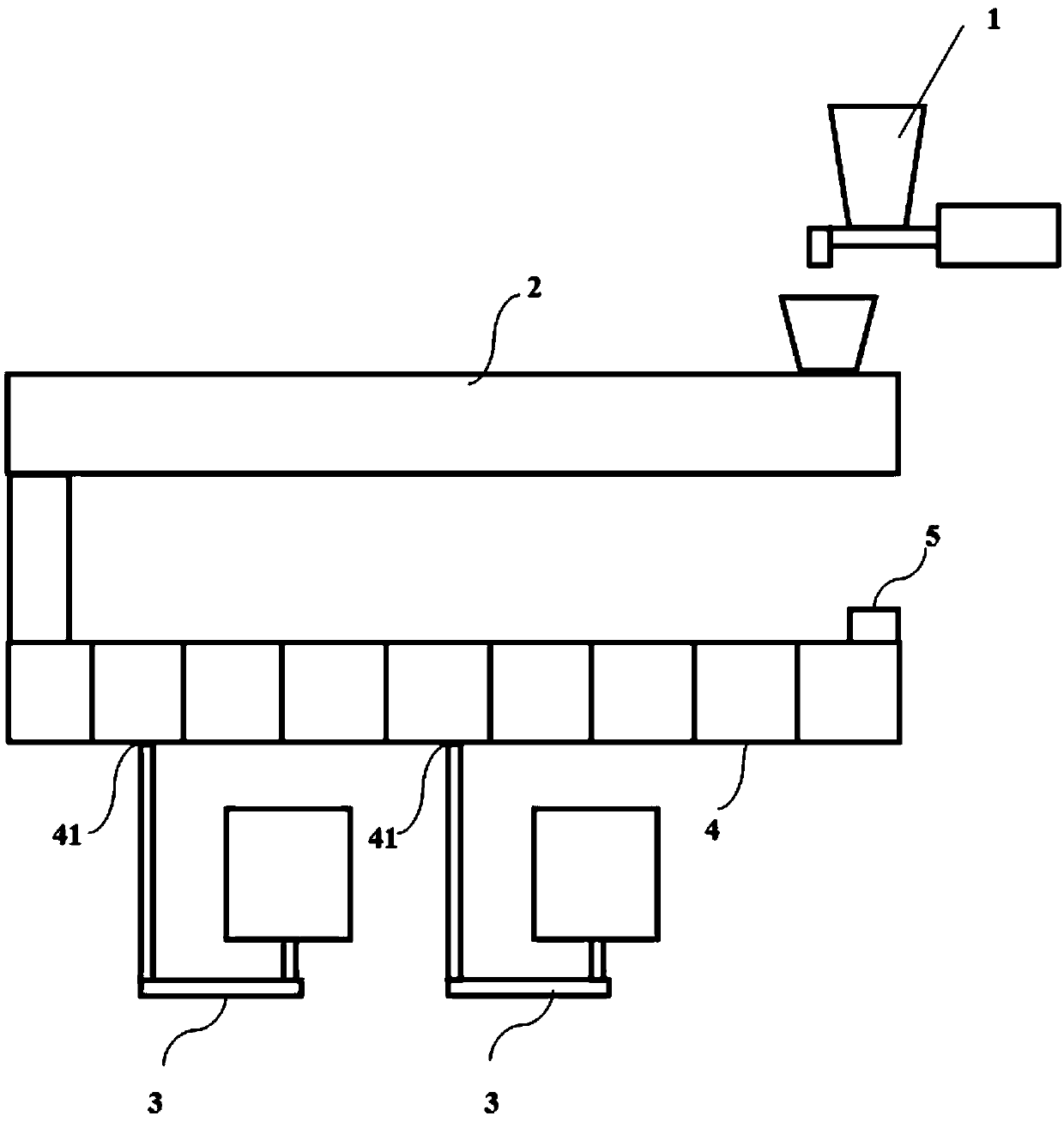

A kind of grafting reaction device and using method thereof

A technology of grafting reaction and melting device, which is applied in the field of grafting reaction device, to achieve the effect of less crystal point, side reaction suppression and small side reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

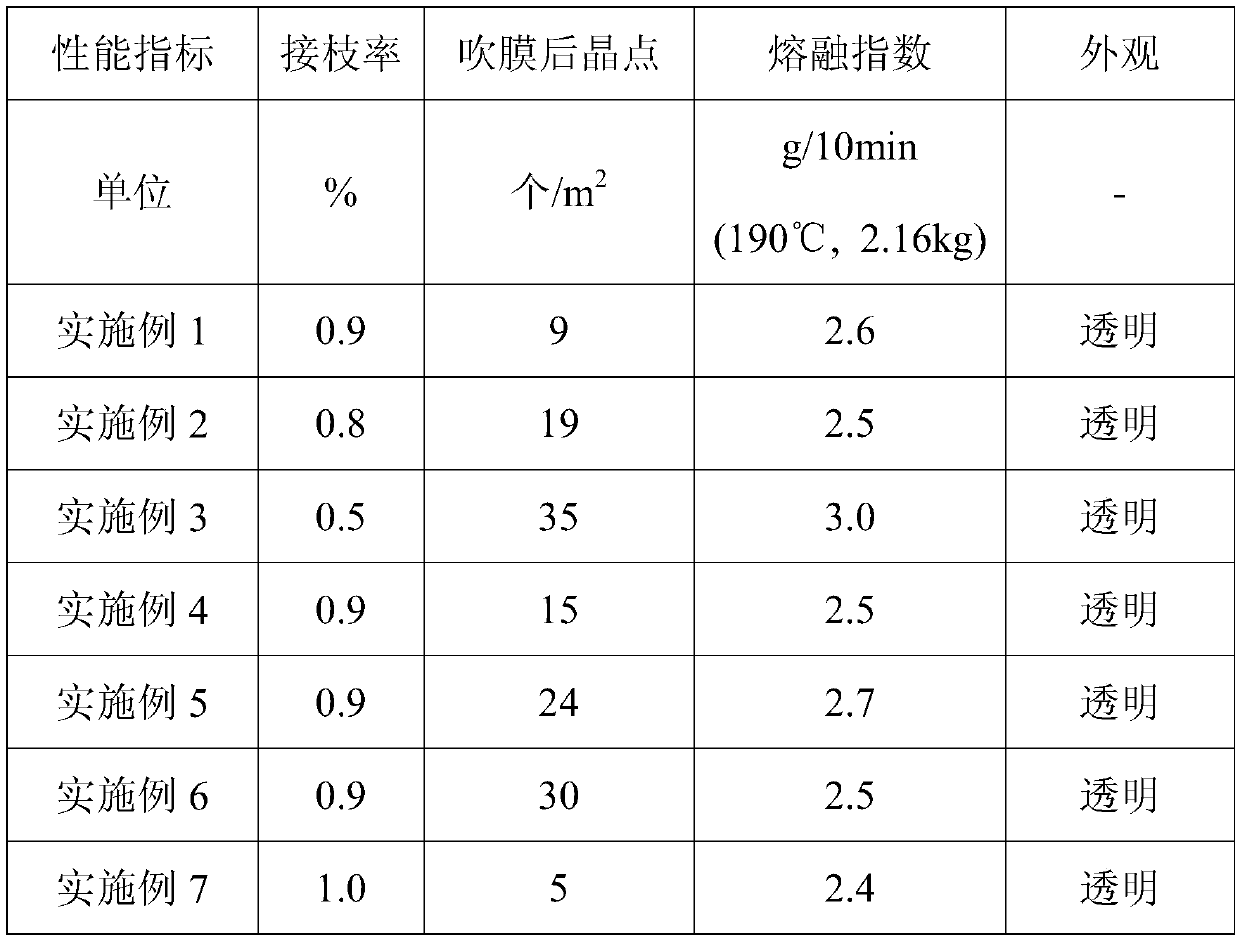

Embodiment 1

[0044] During use, the temperature of the single-screw melting device is set at 190°C, and the screw speed is 300rpm; the temperature of the twin-screw grafting reaction device is set at 140°C, and the screw speed is 300rpm; the auxiliary agent adding device adds the auxiliary agent to the twin-screw grafting reaction device. In the second section and the fifth section, the discharge rate is 1.5kg / h, and the remaining steps and parameters are the same as those in the specific embodiment to obtain the finished product.

Embodiment 2

[0046] During use, the temperature of the single-screw melting device is set at 190°C, and the screw speed is 300rpm; the temperature of the twin-screw grafting reaction device is set at 140°C, and the screw speed is 300rpm; the auxiliary agent adding device adds the auxiliary agent to the twin-screw grafting reaction device. In the second section, the discharge rate is 3kg / h, and all the other steps and parameters are the same as those in the specific embodiment to obtain the finished product.

Embodiment 3

[0048] During use, the temperature of the single-screw melting device is set at 190°C, and the screw speed is 300rpm; the temperature of the twin-screw grafting reaction device is set at 140°C, and the screw speed is 300rpm; the auxiliary agent adding device adds the auxiliary agent to the twin-screw grafting reaction device. In the fifth section, the discharge rate is 3kg / h, and the remaining steps and parameters are the same as those in the specific embodiment to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com