Preparation method of graphene oxide

A graphene and graphite powder technology, applied in the field of graphene oxide preparation, can solve the problems of low oxidation degree of graphene oxide, increased difficulty in waste liquid treatment, high equipment cost, etc. Good spacing and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

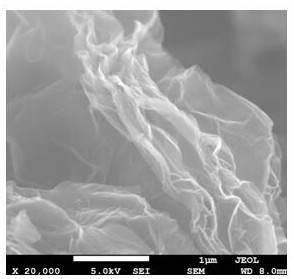

Image

Examples

Embodiment 1

[0048] A preparation method of graphene oxide, comprising the steps of:

[0049] Step 1, low-temperature reaction: Mix concentrated sulfuric acid and phosphoric acid with a mass ratio of 5:1 to prepare the mixed acid and pre-cool it to keep its temperature at 0-2°C;

[0050] In this step, its mass fraction of the concentrated sulfuric acid used is 90%, and its mass fraction of concentrated phosphoric acid is 85%;

[0051] Step 2, oxidation reaction: take a certain amount of mixed acid prepared in step 1 and place it in a jacketed reaction kettle, add natural flake graphite powder with a mesh number of 100 meshes according to the mass ratio under an ice-water bath, fully stir and disperse and press Potassium permanganate was added proportionally, fully stirred and reacted for 0.5 hours;

[0052]In this step, the mass ratio of graphite powder, mixed acid, potassium permanganate is 1:40:3;

[0053] Step 3, medium temperature reaction: switch the water in the jacket of the react...

Embodiment 2

[0062] Embodiment 2: a kind of preparation method of graphene oxide comprises the steps:

[0063] Step 1, low-temperature reaction: mix concentrated sulfuric acid and phosphoric acid with a mass ratio of 15:1 to prepare the mixed acid and pre-cool it to keep its temperature at 8-10°C;

[0064] In this step, its mass fraction of the concentrated sulfuric acid used is 98%, and its mass fraction of concentrated phosphoric acid is 95%;

[0065] Step 2, oxidation reaction: take a certain amount of mixed acid prepared in step 1 and place it in a jacketed reactor, add natural flake graphite powder with a mesh number of 5000 meshes according to the mass ratio under the ice-water bath, fully stir and disperse and press Potassium permanganate was added proportionally, fully stirred and reacted for 5 hours;

[0066] In this step, the mass ratio of graphite powder, mixed acid, potassium permanganate is 1:70:5;

[0067] Step 3, medium temperature reaction: switch the water in the jacket ...

Embodiment 3

[0077] A preparation method of graphene oxide, comprising the steps of:

[0078] Step 1, low-temperature reaction: Mix concentrated sulfuric acid and phosphoric acid with a mass ratio of 5:1 to prepare the mixed acid and pre-cool it to keep its temperature at 0-2°C;

[0079] In this step, its mass fraction of the concentrated sulfuric acid used is 90%, and its mass fraction of the concentrated phosphoric acid is 85~95%;

[0080] Step 2, oxidation reaction: take a certain amount of mixed acid prepared in step 1 and place it in a jacketed reactor, add natural flake graphite powder with a mesh number of 325 mesh under an ice-water bath according to the mass ratio, fully stir and disperse and press Potassium permanganate was added proportionally, fully stirred and reacted for 0.8 hours;

[0081] In this step, the mass ratio of graphite powder, mixed acid, potassium permanganate is 1:40:3;

[0082] Step 3, medium temperature reaction: switch the water in the jacket of the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com