Method for continuously manufacturing potassium diformate

A technology of potassium diformate and formic acid, applied in chemical instruments and methods, carboxylate preparation, carboxylate preparation and other directions, can solve the problem that potassium oxide cannot be directly stored in the air, the source of potassium oxide is small, and it is difficult to industrialize application, etc. It is suitable for large-scale industrial production, the production process is continuous and uninterrupted, and the reaction is mild and controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

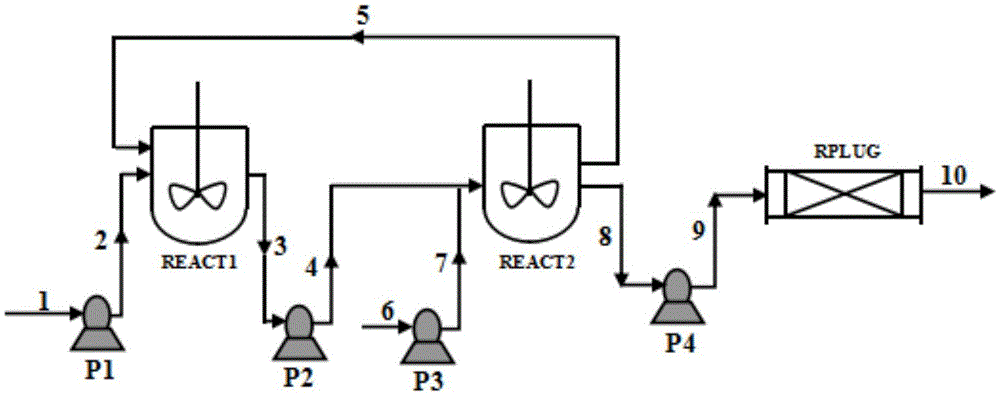

Image

Examples

Embodiment 1

[0029] Embodiment 1: take by weighing potassium hydroxide solid 15.73g (82%), add distilled water and be prepared into potassium hydroxide solution, get half of former potassium hydroxide solution and put into the first reactor, pass into potassium hydroxide solution 0.04mol carbon dioxide gas forms a mixed solution, and the mol ratio of potassium hydroxide and potassium carbonate in the controlled mixed solution is 1.5. Add 30ml of formic acid (the molar ratio of formic acid to potassium ions is 2.6:1) and the mixed solution into the second reactor and stir the reaction with a transfer pump. The reaction temperature is 60°C. While reacting, the remaining potassium hydroxide solution Continue to pass into the first reactor, and continuously extract the product in the second reactor after about two minutes, and react at a temperature of 60°C for 1 hour. After the reaction is stopped, the product solution is distilled under reduced pressure, and it is left to stand at room temper...

Embodiment 2

[0030] Embodiment 2: adopt the feed ratio of example 1, pass into carbon dioxide gas amount to be 0.05mol, control the molar ratio of potassium hydroxide and potassium carbonate in the mixed solution to be 0.80, the reaction temperature is 55 ℃, and the reaction time is 2.5h. All the other conditions and steps are the same as Example 1, and the product is dried to obtain 25.75 g of potassium diformate, and the product yield is 86.17%.

Embodiment 3

[0031] Embodiment 3: take by weighing potassium hydroxide solid 17.04g, formic acid 30ml (formic acid mol and potassium ion molar ratio is 2.4:1) add distilled water and prepare potassium hydroxide solution, pass into carbon dioxide gas amount and be 0.05mol, hydrogen in the mixed solution The molar ratio of potassium oxide to potassium carbonate was 1, the reaction temperature was 65° C., and the reaction time was 2 hours. The remaining conditions and steps were the same as in Example 1. The product was dried to obtain 27.56 g, with a yield of 86.09%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com