Method of preparing high-activity photocatalyst zinc magnesium composite oxide for degradation of organic dyes

A technology of composite oxides and photocatalysts, applied in chemical instruments and methods, water treatment of special compounds, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

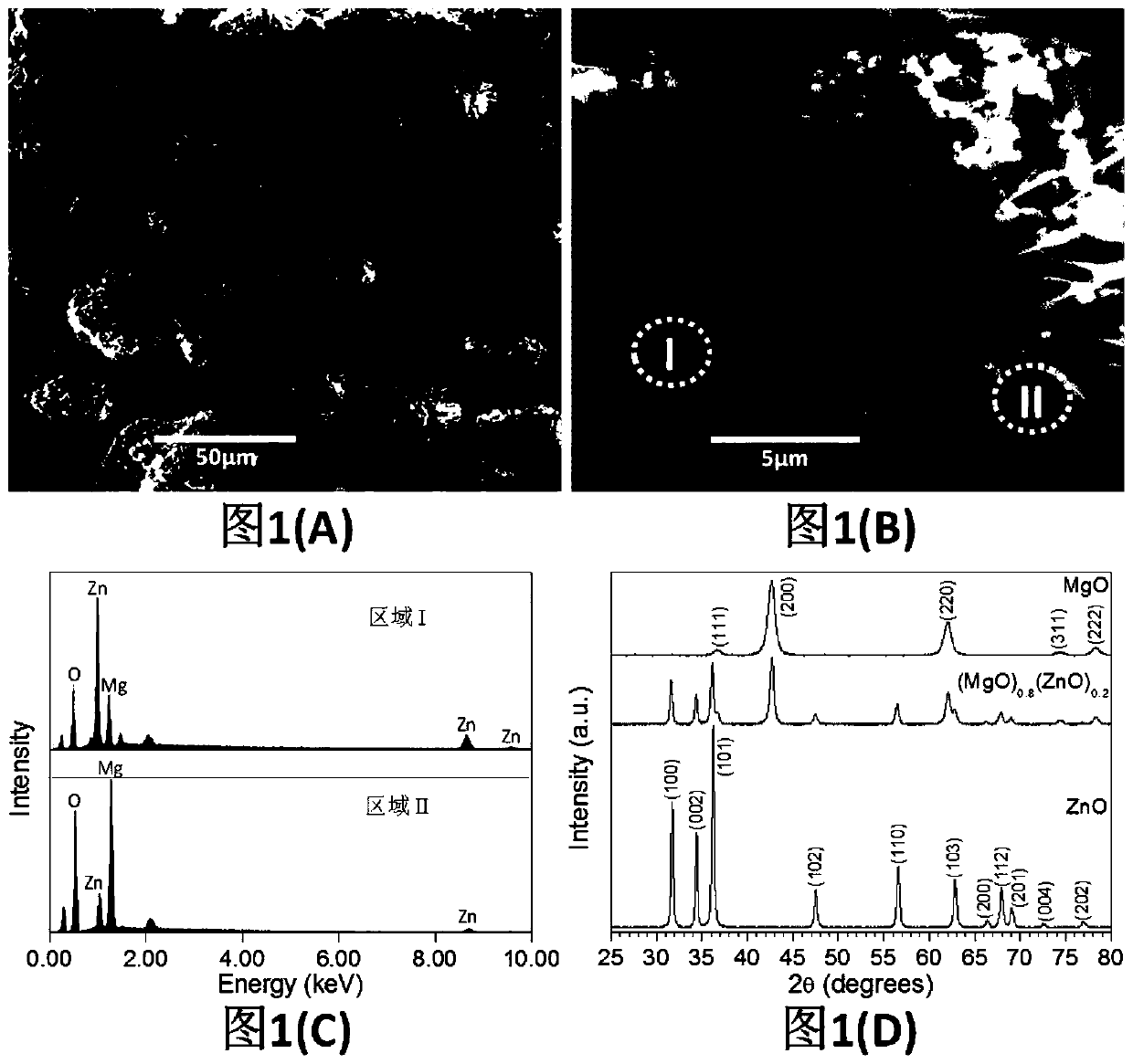

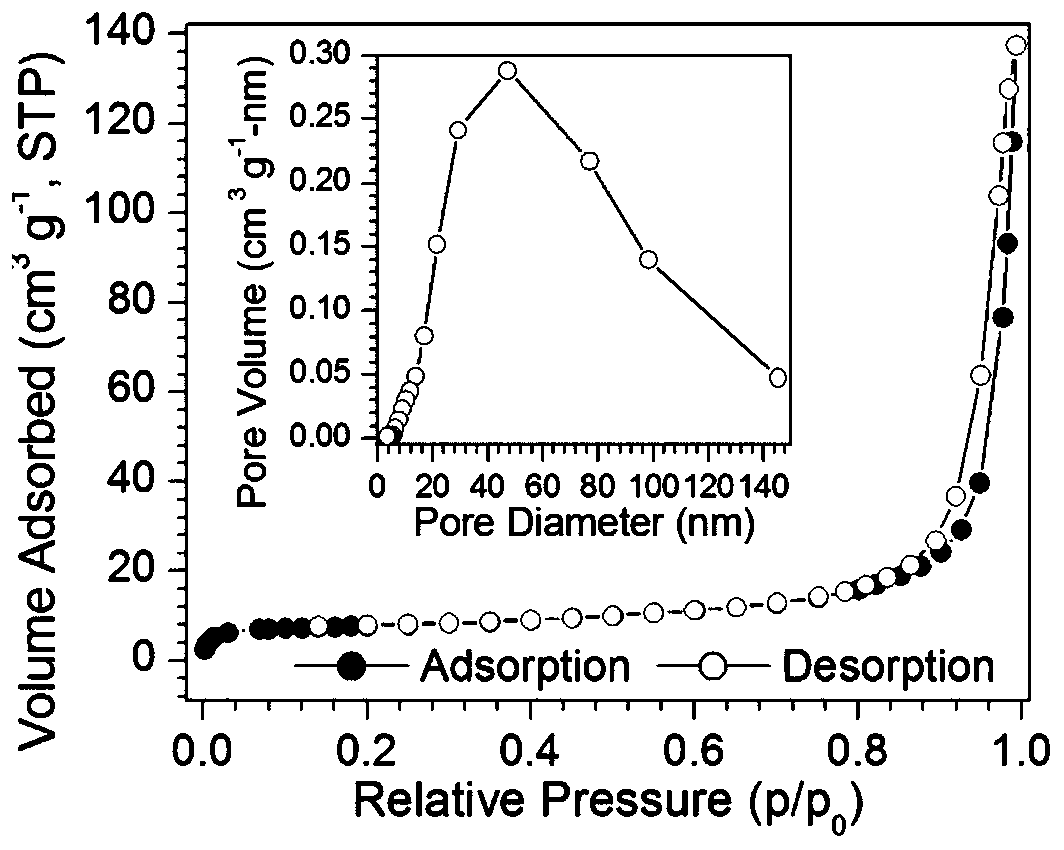

[0022] The preparation method of the present embodiment comprises:

[0023] Accurately weigh 0.04mol of Mg(NO 3 ) 2 ·6H 2 O and 0.01mol of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 50mL deionized water to obtain A solution, and then weighed 0.05mol Na 2 CO 3 Dissolve in 100mL deionized water to obtain solution B, adjust the pH values of the above two solutions to 3.8 and 12.0 respectively; then transfer solution A to a 250mL three-neck round bottom flask and heat to 80°C, under vigorous stirring, Quickly add solution B heated to 80°C into solution A within 4-5s and continue to stir for 3.5 minutes, then leave it to age for 10 hours at a temperature of 80°C, the obtained white precipitate is filtered, washed, After drying at 70°C, spherical Mg with a size of 36 μm was obtained 0.8 Zn 0.2 O particles, put them into a muffle furnace for roasting, the roasting atmosphere is static air, the roasting temperature is 600°C, the heating rate is 5°C / min, and the roasting time is 3...

Embodiment 2

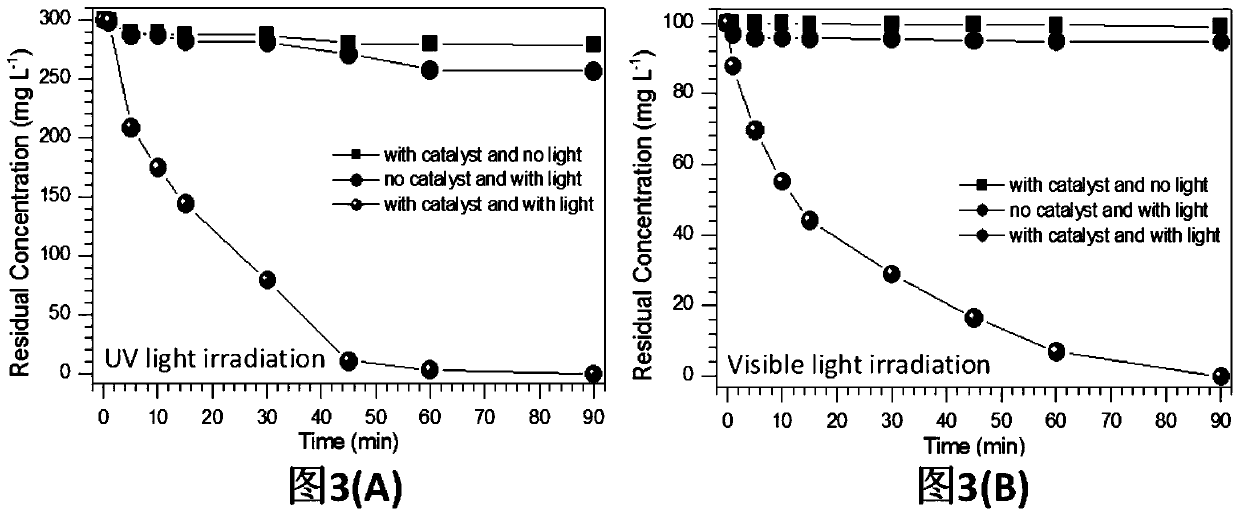

[0026] With the preparation method of Example 1, the difference is to accurately weigh 0.020mol of Mg(NO 3 ) 2 ·6H 2 O, 0.005mol Zn(NO 3 ) 2 ·6H 2 O and 0.025mol Na 2 CO 3 , the zinc-magnesium composite oxide obtained by high-temperature roasting is irradiated with ultraviolet light, and it is effective against 300mg L -1 The photodegradation efficiency of the methylene blue aqueous solution can reach more than 80%.

Embodiment 3

[0028] With the preparation method of Example 1, the difference is to accurately weigh 0.040mol of Mg(NO 3 ) 2 ·6H 2 O, 0.010mol of Zn(NO 3 ) 2 ·6H 2 O and 0.050mol Na 2 CO 3 , the zinc-magnesium composite oxide obtained by 500 ℃ high-temperature roasting is irradiated with ultraviolet light, and it is 300mg L -1 The photodegradation efficiency of the methylene blue aqueous solution can reach more than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com