Method for reducing gelation speed of konjac

A technology of gelation speed and konjac, which is applied in the field of konjac processing, can solve the problems of unusable food, prolong the injection molding time, reduce the gel temperature, etc., and achieve the benefits of injection molding processing, prolong the gelation time, and slow down the gelation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Take 100g of konjac flour, add 400g of alcohol to it, stir and heat to above 40°C and keep it warm for 20 minutes, then add deacetylation agent, the deacetylation agent is 4 parts by weight of sodium tripolyphosphate, 5 parts of disodium hydrogen phosphate, Prepared by adding 1 part of sodium dihydrogen phosphate and 2 parts of trisodium phosphate with water; make the pH 7.5~9 for deacetylation reaction for 60 minutes, after the reaction is completed, adjust the pH to neutral; filter out the alcohol and dry it in vacuum to The moisture content of the powder is 7wt%;

[0033] 2) Add the treated konjac powder into room temperature water 25 times its mass while stirring; then heat to 65~80°C and keep it warm for 30 minutes. After it is fully swollen, add gelling agent and mix evenly. 1 part of raw material D-sodium ascorbate by weight, 6 parts of sodium hexametaphosphate, 3 parts of sodium tripolyphosphate, 7 parts of sodium carbonate, 3 parts of sodium dihydrogen phosp...

Embodiment 2

[0036] 1) Take 100g of konjac flour, add 600g of alcohol to it, stir and heat to above 40°C and keep it warm for 30 minutes, then add a deacetylating agent with a concentration of 3wt%, and the deacetylating agent uses sodium hexametaphosphate and dihydrogen phosphate Prepared by dissolving sodium in water; deacetylating the pH at 7.5-9 for 70 minutes, adjusting the pH to neutral after the reaction; filtering out the alcohol, and drying in vacuum until the moisture content of the powder is 10wt%;

[0037] 2) Add the treated konjac powder into normal temperature water with 40 times its mass while stirring; then heat it to 65~80°C and keep it warm for 60 minutes. After it is fully swollen, add gel agent D with a concentration of 10% - Sodium erythorbate is mixed evenly so that the pH is 8.5~10, and finally poured into the mold, and the konjac gel is formed by using the residual temperature;

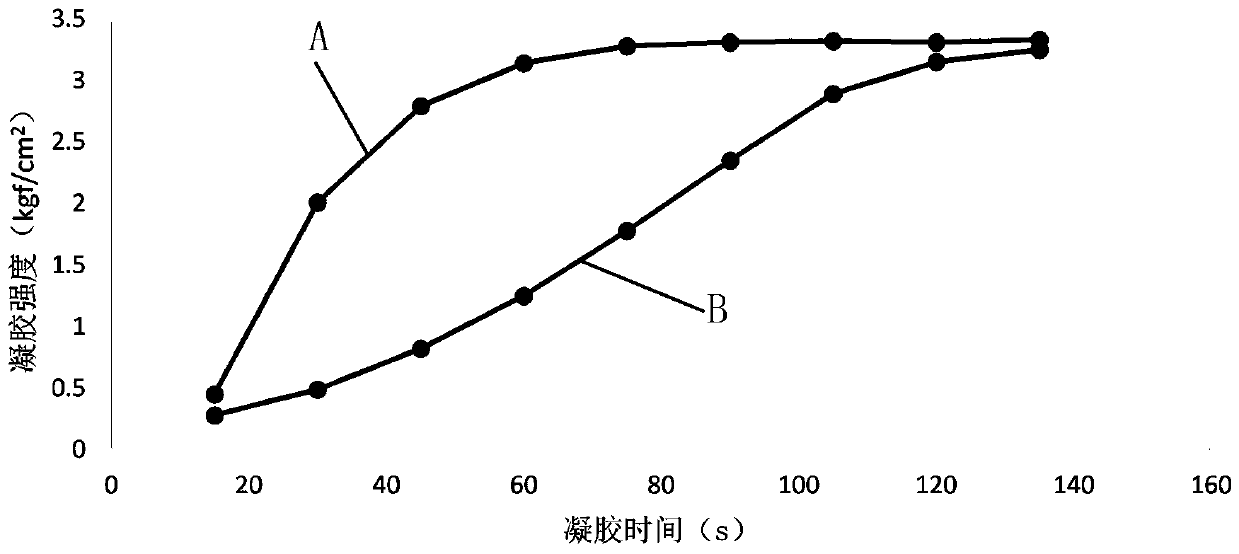

[0038] Through the above operations, the purpose of slowing down the konjac gel speed c...

Embodiment 3

[0040] 1) Take 100g of konjac flour, add 500g of alcohol to it, stir and heat to above 40°C and keep it warm for 30 minutes, then add a deacetylating agent with a concentration of 3wt%, and the deacetylating agent uses sodium tripolyphosphate and dihydrogen phosphate Prepared by dissolving sodium in water; deacetylating the pH at 7.5-9 for 80 minutes, adjusting the pH to neutral after the reaction; filtering out the alcohol, and drying in vacuum until the moisture content of the powder is 8wt%;

[0041] 2) Add the treated konjac powder into normal temperature water with 40 times its mass while stirring; then heat to 65~80°C and keep it warm for 40 minutes. After it is fully swollen, add 10% gelling agent carbonate Mix sodium and D-sodium erythorbate evenly so that the pH is 8.5~10, and finally pour it into the mold, and use the residual temperature to form the konjac gel;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com