Modified poly(lactic acid) and preparation method thereof

A polylactic acid modification technology, applied in the field of modified polylactic acid and its preparation, can solve problems such as degradation of polylactic acid, reduction of mechanical properties, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

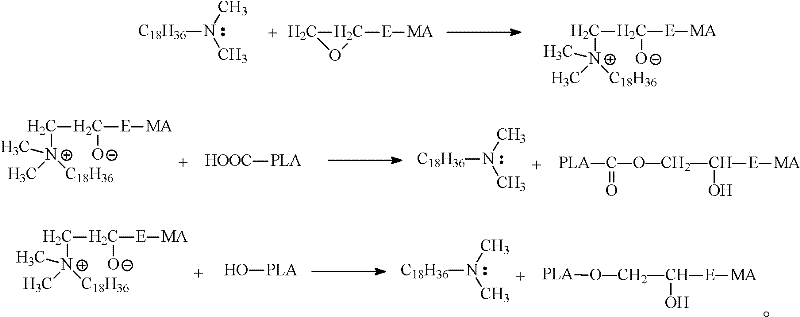

[0028] The present invention also provides a preparation method of modified polylactic acid, comprising: a) premixing polylactic acid, ethylene-acrylate-glycidyl methacrylate copolymer, and a catalyst to obtain a resin composition; It is a tertiary amine or phosphorus catalyst; b) melting and kneading the resin composition at 160-200° C. to undergo a ring-opening reaction to obtain modified polylactic acid.

[0029] According to the present invention, taking N, N-dimethyl octadecylamine as an example, the reaction process of the present invention is as follows:

[0030]

[0031]Pre-mix E-MA-GMA, polylactic acid and catalyst at 150-180°C, the pre-mixing time is preferably 2-3 minutes, the purpose of pre-mixing is to fully mix the raw materials, and pre-plasticize, so that the reaction proceeds more smoothly full. According to the present invention, the equipment used for the premixing is preferably an internal mixer, an open mixer, and a high-speed mixer.

[0032] The prem...

Embodiment 1

[0035] In parts by weight, 15 parts of E-MA-GMA elastomer, 0.3 part of N, N-dimethylisopropanolamine and 85 parts of polylactic acid are taken. Polylactic acid, E-MA-GMA elastomer, N,N-dimethylisopropanolamine are premixed, and then melt blended in an internal mixer. The blending temperature is 180° C., the rotation speed is 80 r / min, and the mixing time is 5 min. And keep the temperature, rotational speed and mixing time constant throughout the experiment.

[0036] The impact resistance test of the modified polylactic acid prepared by the present invention is carried out on the XJU-22J type Izod impact testing machine manufactured by Chengde Testing Machine Factory. The average value of ten determinations was detected. The notched impact strength of the obtained material is 69.4kJ / m 2 .

Embodiment 2

[0038] In parts by weight, 20 parts of E-MA-GMA elastomer, 0.2 part of 4-amino-N, N-dimethylaniline and 80 parts of polylactic acid are taken. Polylactic acid, E-MA-GMA elastomer, 4-amino-N, N-dimethylaniline are premixed, and then melt blended in an internal mixer. The blending temperature is 180° C., the rotation speed is 80 r / min, and the mixing time is 5 min. And keep the temperature, rotational speed and mixing time constant throughout the experiment.

[0039] Detect the notched impact strength of the modified polylactic acid prepared in this embodiment according to the method of Example 1, and the notched impact strength of the obtained material is 80.8kJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com