Denitration catalyst and preparation method thereof

A technology of denitration catalyst and composite catalyst, which is applied in the field of denitration catalyst and its preparation, can solve the problems of high ash content, high ash content of flue gas, catalyst wear, etc., achieve high hardness and wear resistance, huge pore structure, and improve the effect of SO2 resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

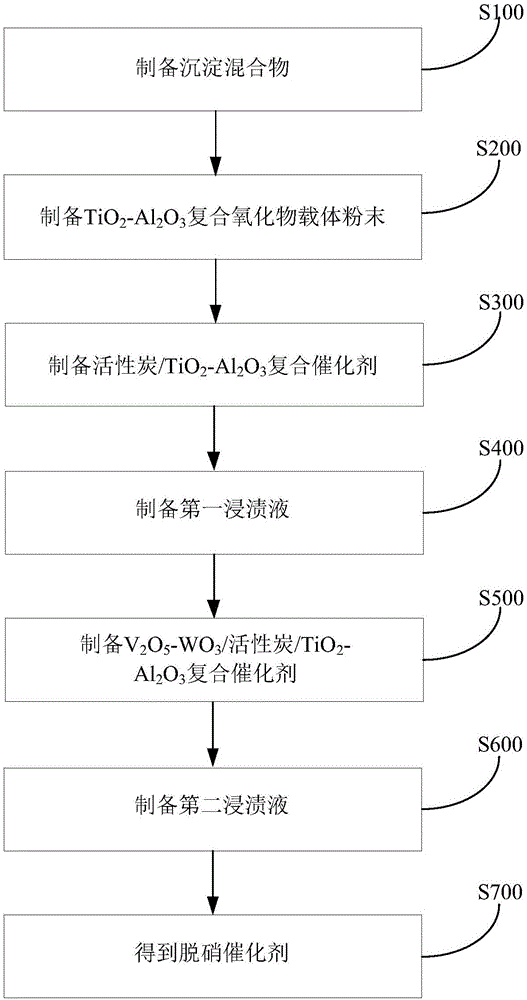

Method used

Image

Examples

Embodiment 1

[0065] 1. Preparation of carrier

[0066] Take 43.96g of titanyl sulfate and 36.64g of aluminum chloride, dissolve them in an appropriate amount of deionized water, and stir them evenly to prepare a titanium source solution and an aluminum source solution respectively, and the concentration ratio of the two is 1:1. The obtained titanium source solution, aluminum source solution, and ammonia water are dripped into a reaction kettle at a certain flow rate in a co-current manner, and a stirring device is installed in the reaction kettle. The dripping speed of the titanium source solution and the aluminum source solution is the same, the dripping speed of ammonia water is controlled, the pH value of the reaction solution is controlled at 10, and a precipitation mixture of titanium hydroxide and aluminum hydroxide is obtained by co-precipitation. Suction filtration and washing of the precipitate were repeated several times until the pH value of the filtrate reached about 7. After ...

Embodiment 2

[0077] 1. Preparation of carrier

[0078] Take 72.77g of titanyl sulfate and 30.33g of aluminum chloride, dissolve them in an appropriate amount of deionized water, and stir them evenly to prepare a titanium source solution and an aluminum source solution respectively, and the concentration ratio of the two is 1:0.5. The obtained titanium source solution, aluminum source solution, and ammonia water are dripped into a reaction kettle at a certain flow rate in a co-current manner, and a stirring device is installed in the reaction kettle. The dripping speed of the titanium source solution and the aluminum source solution is the same, the dripping speed of ammonia water is controlled, the pH value of the reaction solution is controlled at 10, and a precipitation mixture of titanium hydroxide and aluminum hydroxide is obtained by co-precipitation. Suction filtration and washing of the precipitate were repeated several times until the pH value of the filtrate reached about 7. Afte...

Embodiment 3

[0089] 1. Preparation of carrier

[0090]Take 37.79g of titanyl sulfate and 63.01g of aluminum chloride, dissolve them in an appropriate amount of deionized water, and stir them evenly to prepare titanium source solution and aluminum source solution respectively, and the concentration ratio of the two is 1:2. The obtained titanium source solution, aluminum source solution, and ammonia water are dripped into a reaction kettle at a certain flow rate in a co-current manner, and a stirring device is installed in the reaction kettle. The dropping speed of the titanium source solution and the aluminum source solution is the same, the dropping speed of ammonia water is controlled, the pH value of the reaction solution is controlled at 10, and a precipitation mixture of titanium hydroxide and aluminum hydroxide is obtained by co-precipitation. Suction filtration and washing of the precipitate were repeated several times until the pH value of the filtrate reached about 7. After drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com