Preparation method of non-high-temperature resistant base material loaded with controllable-crystal nano titanium dioxide on surface

A nano-titanium dioxide, substrate surface technology, applied in the direction of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problems of affecting effective contact, separation difficulty, substrate burning, etc., to achieve good bonding firmness, preparation The effect of simple process and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 2ml of pure water to 75ml of absolute ethanol system dissolved with 1ml of tetrabutyl titanate, stir for half an hour and let it stand, centrifuge or settle naturally to separate the white precipitate titanium hydroxide, wash it with water and ethanol for 1 Once, dry at 50°C. Weigh 180mg of dry white titanium hydroxide and mix with 18ml of pure water, stir at high speed for 10 minutes, add 20ml of 30% H 2 o 2 The precipitate was completely dissolved to obtain a treatment solution for loading.

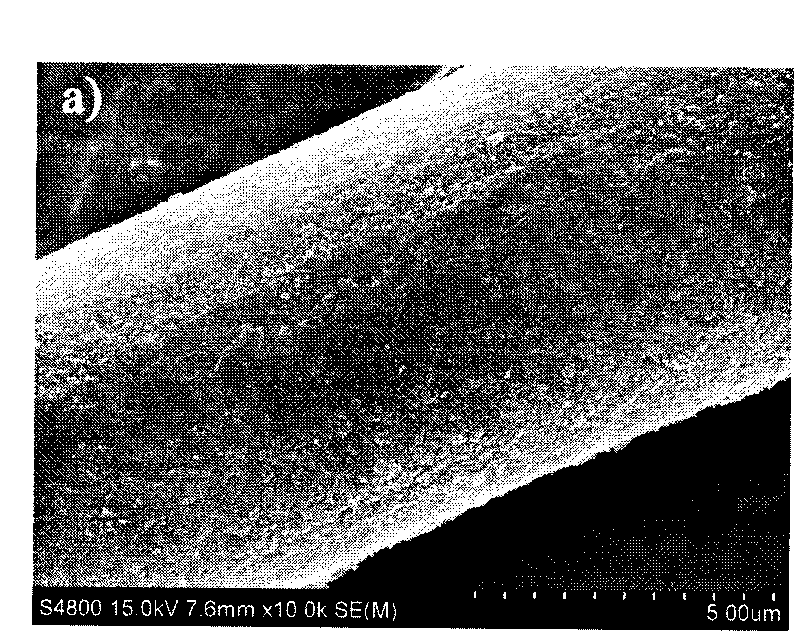

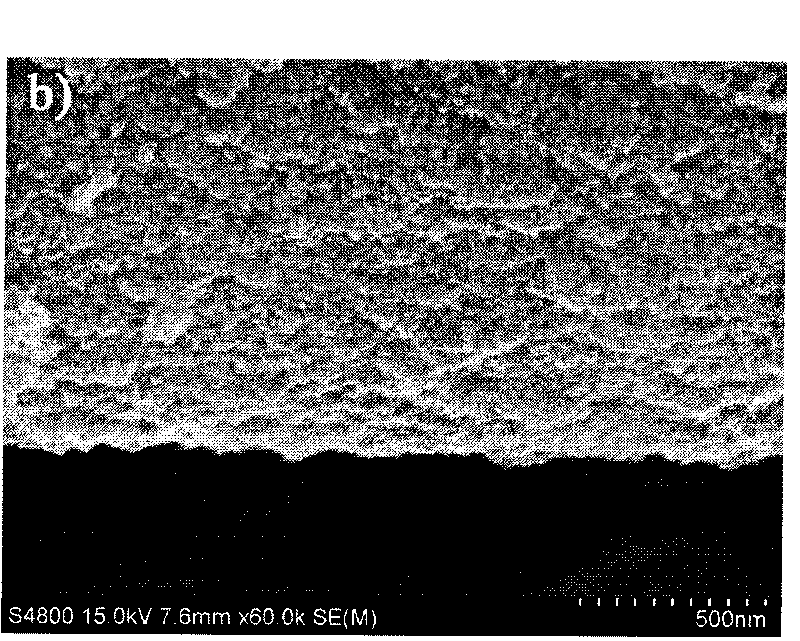

[0032] Weigh 2.0g of carbon fiber, soak and wash with acetone (or acetone organic solvent or ethanol) and pure water for 5 minutes each, and place it in 68% HNO after drying 3 Oxidize at 50°C for 2.5 hours, take it out, wash with pure water to remove residual acid, and dry at 50°C. Immerse the obtained fiber in the above-mentioned treatment solution for loading, keep it warm at 88°C for 40 hours, take it out, wash it with pure water for 3 times, and dry it naturally or at ...

Embodiment 2

[0034] Add 2ml of pure water to 75ml of absolute ethanol system dissolved with 1ml of tetrabutyl titanate, stir for half an hour and let it stand, centrifuge or settle naturally to separate the white precipitate titanium hydroxide, wash it with water and ethanol for 1 Once, dry at 50°C. Weigh 100mg of dry white titanium hydroxide and mix with 10ml of pure water, stir at high speed for 10 minutes, add 12ml of 30% H 2 o 2 The precipitate was completely dissolved to obtain a treatment solution for loading.

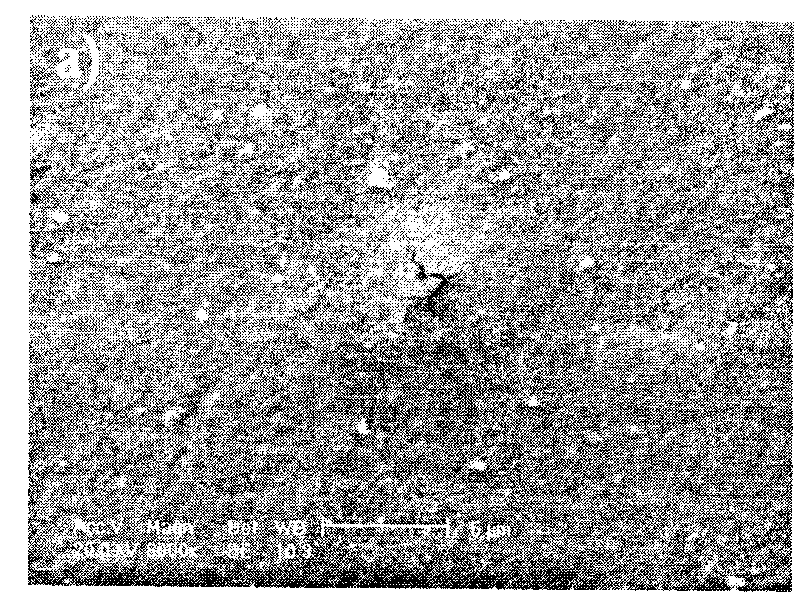

[0035] Weigh 1.0g of carbon fiber, soak and wash it with acetone (or acetone organic solvent or ethanol) and pure water for 15 and 5 minutes respectively, dry it at 50°C and immerse it in the above-mentioned treatment solution for loading, and keep it at 85°C for 50 hours. Take it out, wash it with pure water three times, and dry it naturally or at 60°C. image 3 b is the XRD pattern of anatase and rutile mixed crystal nano-titanium dioxide obtained in Example 2.

Embodiment 3

[0037] Mix 1 mol / L sodium hydroxide solution with 0.8 mol / L titanyl sulfate solution, stir for half an hour and let it stand, centrifuge or settle naturally to separate the white precipitate titanium hydroxide, wash it twice with water, and bake at 50°C Dry. Weigh 50 mg of dry white titanium hydroxide and mix with 8 ml of pure water, stir at high speed for 10 minutes, add 10 ml of 30% H 2 o 2 The precipitate was completely dissolved to obtain a treatment solution for loading.

[0038] Take 20×20×1mm 3 2 pieces of polymethyl methacrylate sheets, soak and wash with acetone (or acetone organic solvent or ethanol) and pure water for 10 minutes in turn, and place them in 3mol / L sodium hydroxide solution at 50°C for 20 minutes after drying. After taking it out, wash it with pure water and dry it at 50°C. Immerse the treated polymethyl methacrylate sheet in the above treatment solution for loading, keep it warm at 80°C for 35 hours, take it out, wash it with pure water for 3 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com