Preparation method of aqueous nano-TiO2 colloid

A nano-titanium dioxide, water colloid technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology and other directions, can solve the problems of complex process, difficult dispersion, complex process, and achieve simple production technology and production equipment, coating good film-forming ability and strong photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

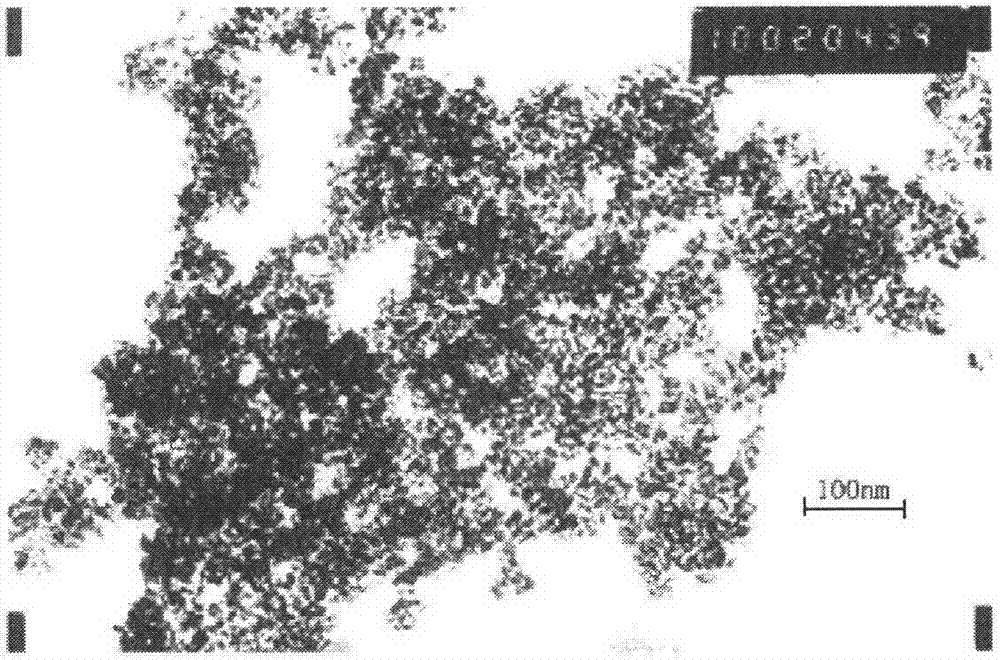

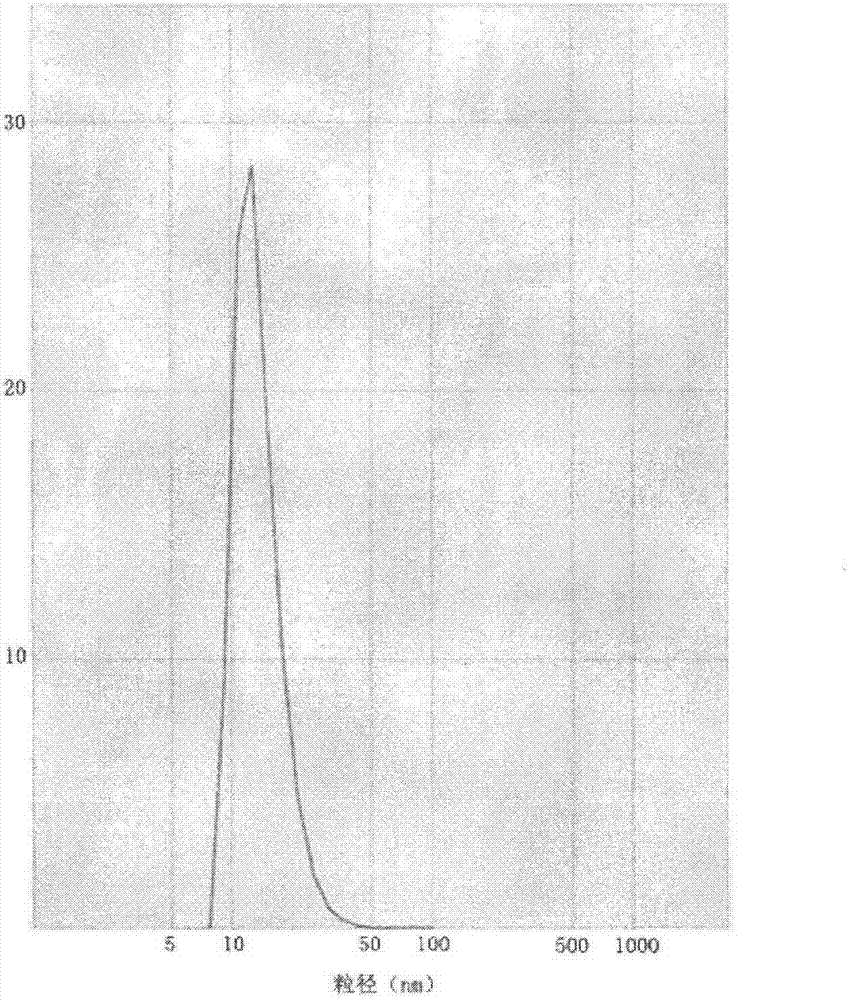

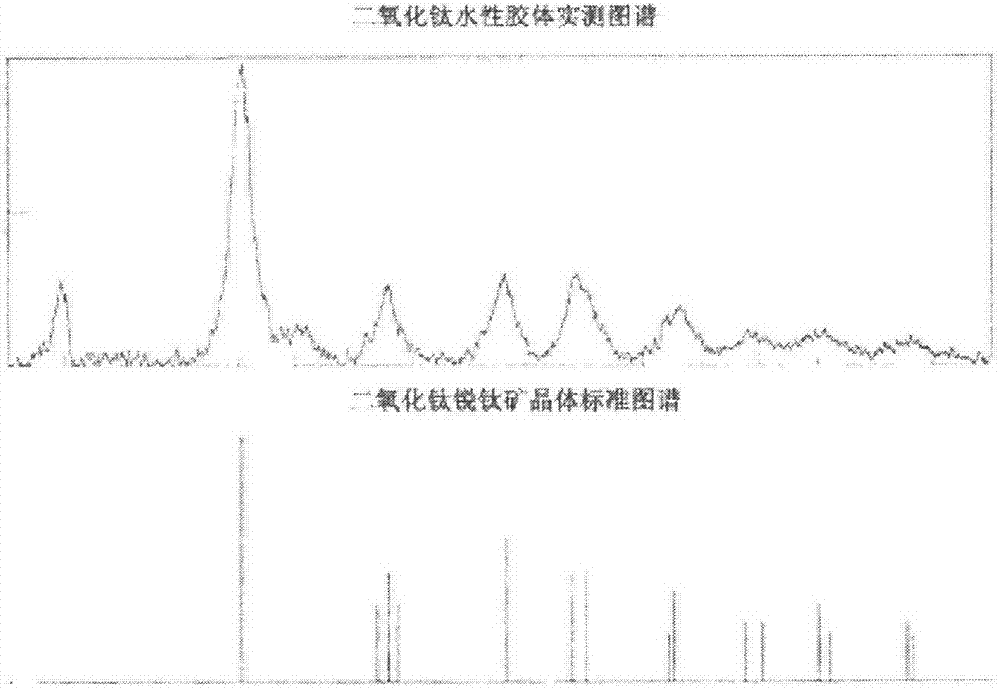

Image

Examples

preparation example Construction

[0013] A preparation method of nano-titanium dioxide hydrocolloid, comprising the following steps: a, supply of raw materials: select titanate, inorganic acid and deionized water as raw materials, prepare a temperature-controlled water bath device, wherein the main raw material of titanate can be titanium Any one of ethyl titanate, propyl titanate or butyl titanate, the inorganic acid can be any one of hydrochloric acid, sulfuric acid or nitric acid, and deionized water is used as the medium, also known as pure water;

[0014] b. Hydrolysis: first pour deionized water into a temperature-controlled water bath device, then add titanate into deionized water, the molar ratio of titanate to deionized water is 1:70-120, and Stir while adding, so that the titanate is completely hydrolyzed into titanium hydroxide;

[0015] c, acidification: add inorganic acid in the obtained titanium hydroxide hydrolyzate, the mol ratio of titanium hydroxide and inorganic acid is 1: 0.2~0.8, makes the...

Embodiment 1

[0019] Ethyl titanate was added into pure water under stirring to completely hydrolyze it into titanium hydroxide. Then add hydrochloric acid to make the pH value of the hydrolyzate around 3, and stir at normal temperature and pressure for 20 minutes. Heating in a water bath to make the temperature of the hydrolyzate reach about 60°C, stirring and reacting at constant temperature and normal pressure for 8 hours, at this time, the titanium hydroxide precipitate gradually dissolves and gels into a water sol. The molar ratio of ethyl titanate, water, and hydrochloric acid is 1:70:0.2.

Embodiment 2

[0021] Propyl titanate was added into pure water under stirring to completely hydrolyze it into titanium hydroxide. Then add sulfuric acid to make the pH value of the hydrolyzate around 2, and stir for 20 minutes at normal temperature and pressure. Heating in a water bath to make the temperature of the hydrolyzate reach about 80°C, stirring and reacting at constant temperature and normal pressure for 6 hours, at this time, the titanium hydroxide precipitate gradually dissolves and gels into a water sol. The molar ratio of propyl titanate, water and sulfuric acid is 1:90:0.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com