Low-temperature preparation method of copper sulfide/titanium oxide hetero-junction photocatalyst

A photocatalyst, heterojunction technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of difficult to deal with solubility industrial wastewater and waste gas, hinder the development and application of industrialization, catalyst The problem of high preparation cost is to achieve the effect of improving photocatalytic efficiency, low price and improving photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

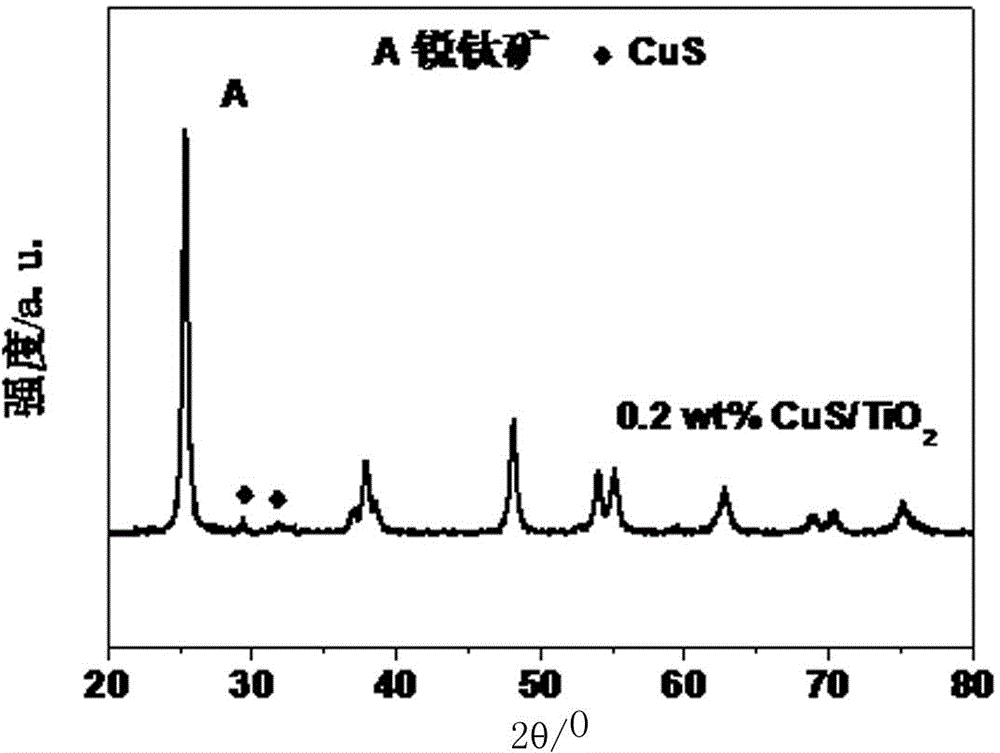

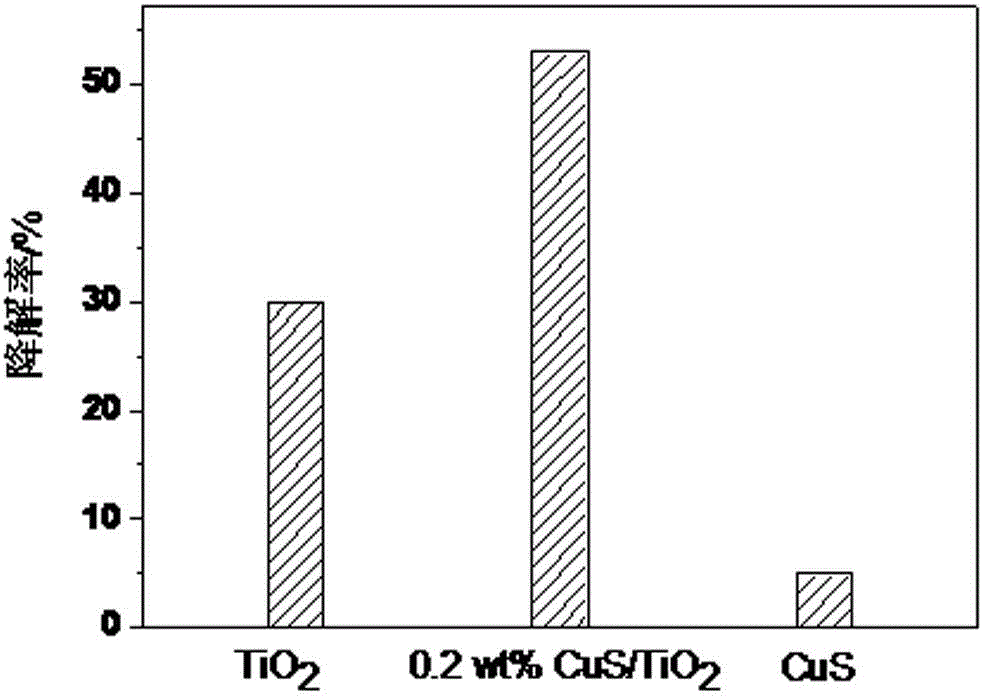

[0041] Low-temperature Preparation and Photocatalytic Activity of Copper Sulfide / Titanium Oxide (Anatase Phase) Heterojunction Photocatalyst

[0042] 1.1CuS / TiO 2 (Anatase crystal phase) The low-temperature preparation method of heterojunction photocatalyst comprises the following steps:

[0043] (1) Add 40ml Ti(OBu) 4 Dissolve in 200ml of absolute ethanol and stir well, slowly add ammonia water dropwise to the solution under full stirring to adjust pH=9, and then continue stirring for 24h. The precipitate was filtered and washed twice with deionized water and absolute ethanol, and then dried at 110 °C to obtain Ti(OH) 4 ;

[0044] (2) At a temperature of 400°C, the Ti(OH) obtained in step (1) 4 Carry out roasting, roasting 2h, obtain TiO 2 Carrier (anatase crystal phase);

[0045] (3) Disperse 0.0201g of copper powder and 0.0106g of sulfur powder in a mixed solvent of ethylene glycol and water (the volume ratio of ethylene glycol and water is 5:1), and 15.013g of TiO 2...

Embodiment 2

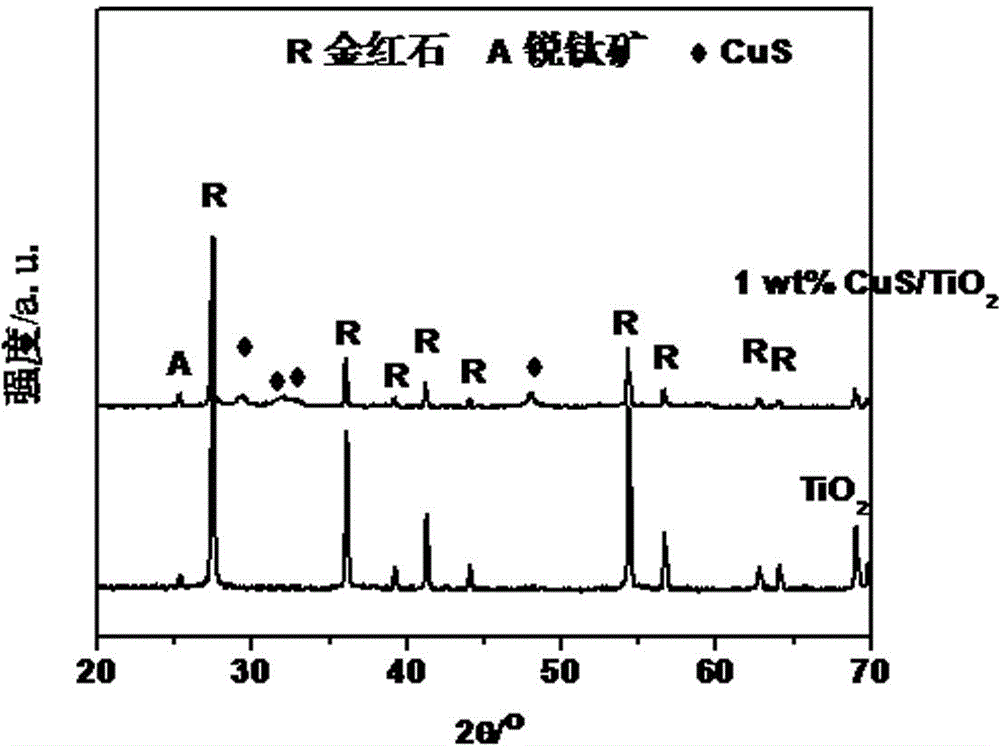

[0055] Low-temperature Preparation and Photocatalytic Activity of Copper Sulfide / Titanium Oxide (Anatase and Rutile Mixed Crystal Phase) Heterojunction Photocatalyst

[0056] 2.1CuS / TiO 2 (Anatase and rutile mixed crystal phase) The low-temperature preparation method of the heterojunction photocatalyst comprises the following steps:

[0057] (1) Dissolve 100ml of TTIP in 400ml of absolute ethanol and stir thoroughly to obtain a light yellow solution. This solution is slowly added to the mixed solution of 200ml absolute ethanol and deionized water (the volume ratio of absolute ethanol and deionized water is 1:5), continue stirring, after the solution becomes a transparent sol, stand still to obtain Clear gel. Then most of the solvent was evaporated in a water bath, and the product was dried at 110°C for 12 hours to obtain Ti(OH) 4 ;

[0058] (2) At a temperature of 650°C, the Ti(OH) obtained in step (1) 4 Carry out roasting, roasting 4h, obtain TiO 2 Carrier (mixed crysta...

Embodiment 3

[0075] Low-temperature Preparation of Copper Sulfide / Titanium Oxide (Anatase and Rutile Mixed Phase) Heterojunction Photocatalyst

[0076] 3.1CuS / TiO 2 (Anatase and rutile mixed crystal phase) The low-temperature preparation method of the heterojunction photocatalyst comprises the following steps:

[0077] (1) Prepare 0.2mol / L TiCl 4 solution, the TiCl 4 The solution was slowly added to deionized water, followed by NH 3 ·H 2 O to adjust the pH to around 8. After stirring for 4 h, the precipitate was filtered, and the resulting precipitate was thoroughly washed with distilled water until AgNO 3 The solution cannot detect chloride ions in the filtrate, which is then dried at 110 °C to obtain Ti(OH) 4 ;

[0078] (2) At a temperature of 550°C, the Ti(OH) obtained in step (1) 4 Carry out roasting, roasting 2h, obtain TiO 2 Carrier (mixed crystal phase of anatase and rutile);

[0079] (3) Disperse 0.0504g of copper powder and 0.0250g of sulfur powder in a mixed solution of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com