Preparation method of nano-silver composite titanium dioxide sol photocatalyst, masking liquid, component and usage

A technology of titanium dioxide and photocatalyst, which is applied in the field of nano-silver composite titanium dioxide sol photocatalyst, which can solve the problems that the powder and catalyst are exposed to ultraviolet light and the process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

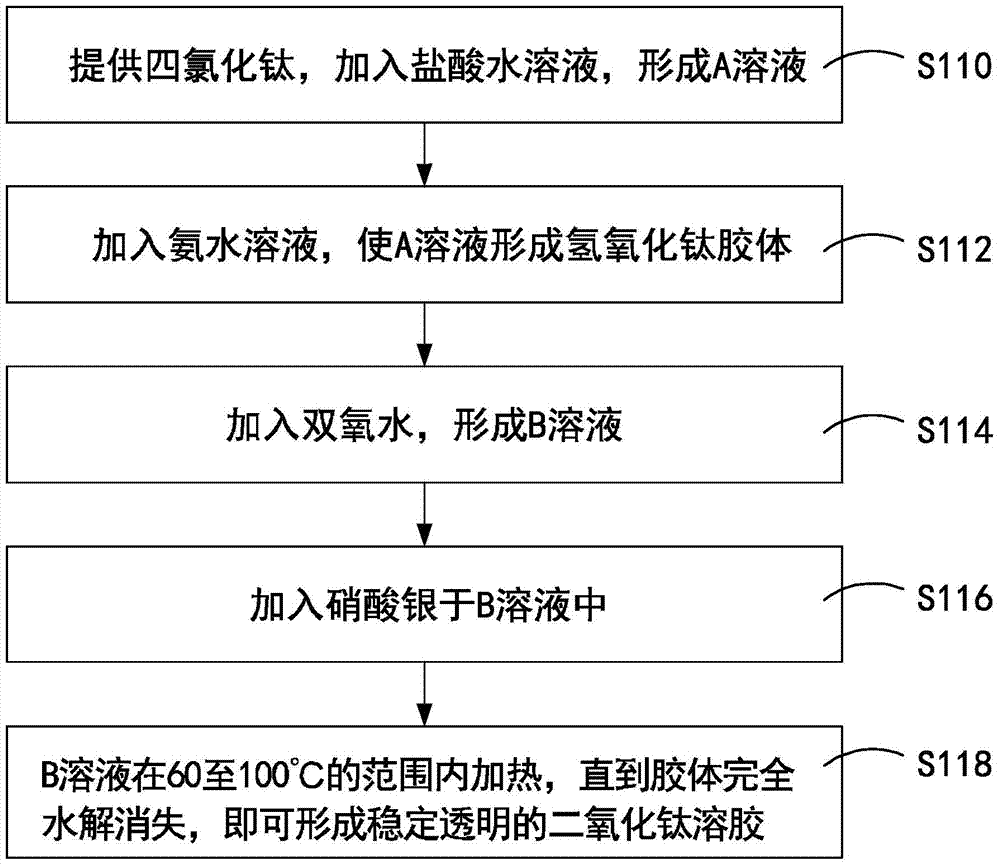

[0027] see figure 1 , figure 1 A flow chart of the method for preparing titanium dioxide sol photocatalyst according to an embodiment of the present invention. A method for preparing a titanium dioxide sol photocatalyst, the steps comprising:

[0028] a. Step S110, providing titanium tetrachloride, adding hydrochloric acid aqueous solution at 0-5°C to form A solution;

[0029] b. Step S112, adding NH 4 OH alkaline solution to form titanium hydroxide colloid, the pH value of which is in the range of 7 to 12;

[0030] c. step S114, adding silver nitrate, AgNO 3 / TiO 2 The weight ratio is from 1 / 10 to 1 / 1000, preferably from 10% to 0.01% by weight;

[0031] d. Step S116, adding hydrogen peroxide to form B solution, TiO 2 / H 2 o 2 The weight ratio of hydrogen peroxide is between 1 / 2 and 1 / 10, and the molar ratio of hydrogen peroxide and titanium is preferably between 2 to 1 and 5 to 1. TiO 2 / H 2 The weight ratio of O is between 0.01% and 2%, preferably between 1 / 200 an...

Embodiment 1

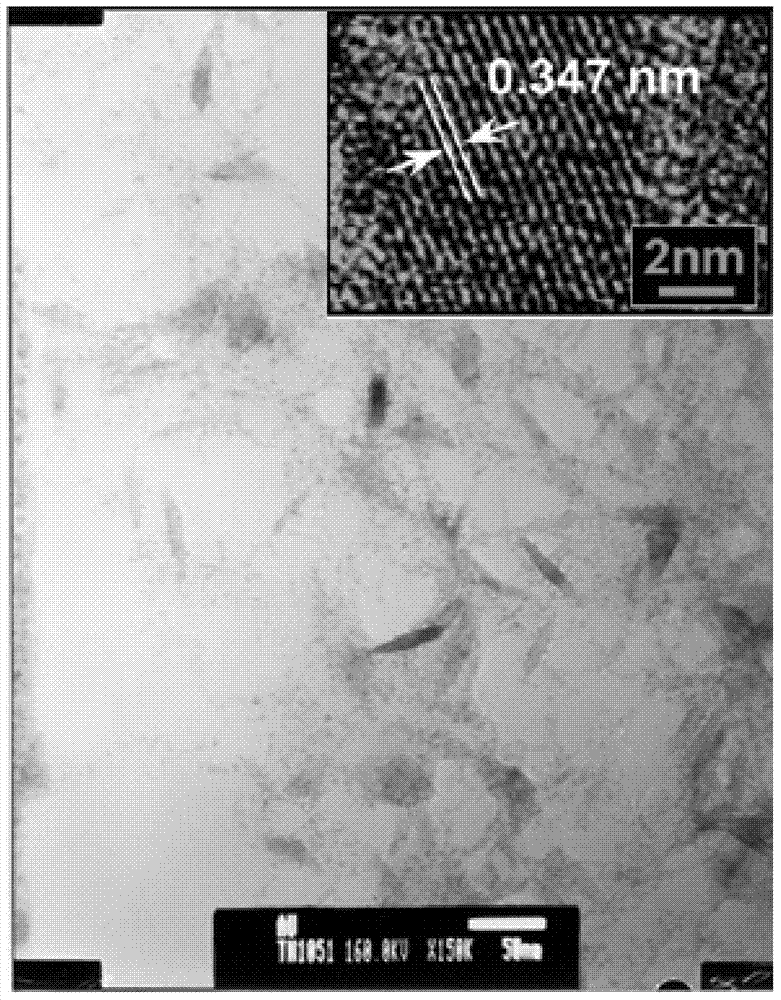

[0036] In an ice bath at 0°C, the TiCl 4 Slowly drop into distilled water to make 5 molar concentration (5M), then slowly add the above solution with 30% ammonia water, and keep stirring until the pH value of the solution is 7, after several times of centrifugation and washing, until the concentration of chlorine Below 5000ppm, then add it to distilled water, and add hydrogen peroxide and silver nitrate, its TiO 2 / H 2 o 2 / H 2 O / AgNO 3 The weight ratio ratio is 1 / 2 / 97 / 0.05 (weight ratio). This solution is placed in a three-necked conical flask, connected to a condenser tube, and heated at 90°C for 2 hours to obtain a nano-scale titanium dioxide sol, such as figure 2 shown.

Embodiment 2

[0038] With embodiment 1, only the weight ratio that adds silver nitrate / titanium dioxide is 2 / 100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com