Titanium-silicon composite oxide carrier and preparation method thereof

A composite oxide and composite hydroxide technology, which can be used in catalyst carriers, chemical instruments and methods, catalyst activation/preparation, etc., and can solve the problems of small pore size and narrow application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

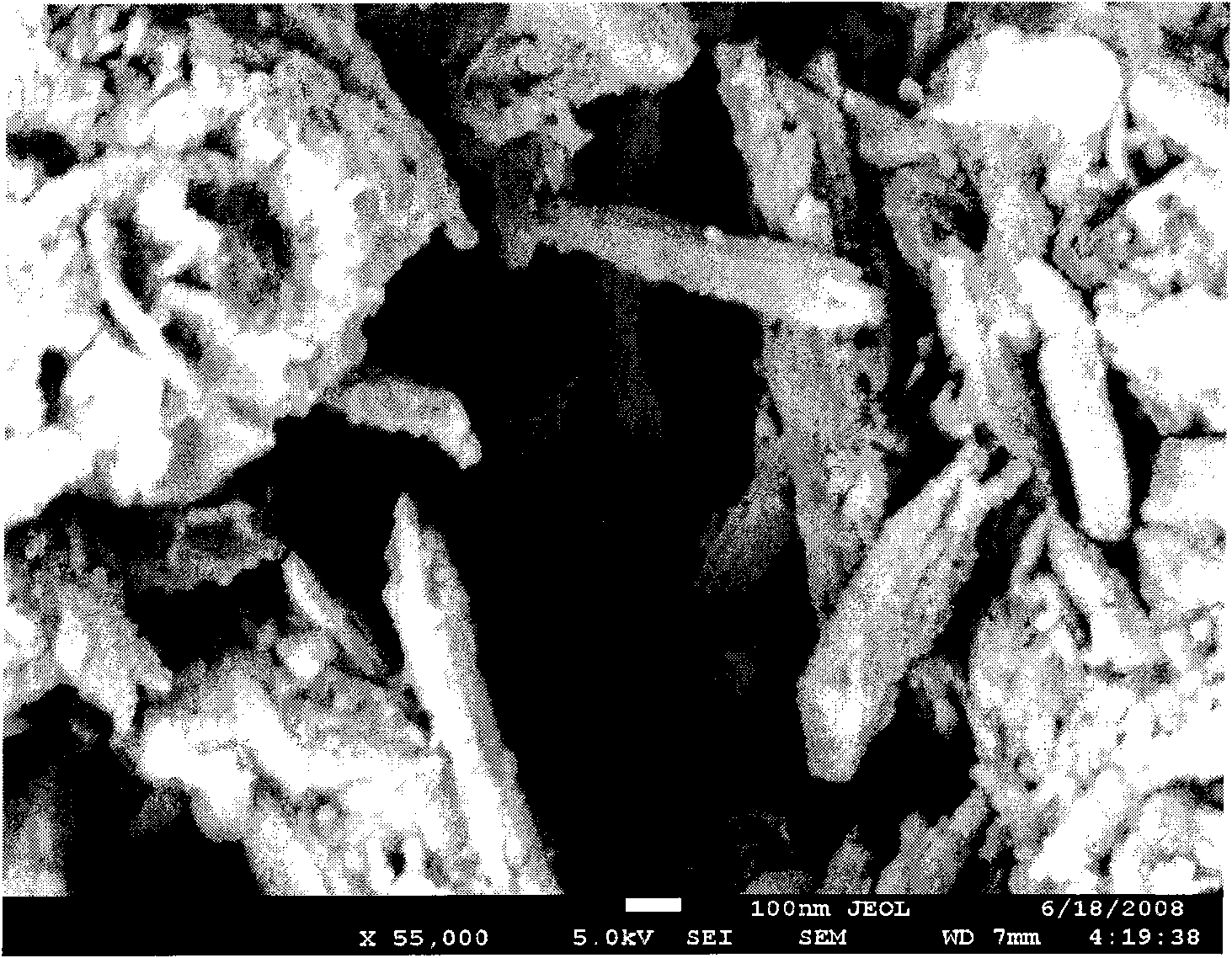

Embodiment 1

[0050] 40g of silica sol and 240g of urea were heated and mixed evenly, slowly added to the mixture of 105g of second-line distillate oil and 20g of polyisobutenyl triethanolamine maleate at 90°C, and mixed for 10 minutes at this temperature. Dissolve 149g of titanium tetrachloride in 200ml of ethanol, then add to the micelles, and mix well. At a temperature of 120°C, the temperature and pressure were maintained, and the reaction was carried out for 6 hours. After the reaction, wash with distilled water until there is no negative ion, and centrifuge. Finally, it was dried at 100° C. for 10 hours. Nano-titanium hydroxide-silicon hydroxide gel dry powder 80g is mixed homogeneously with binding agent pseudo-boehmite 20g; 3.2g dilute nitric acid (mass concentration 17%), 15g water and 3g cosolvent ethanol are mixed homogeneously, then Molded in extruder, control pressure at 23MPa. The molded product was dried at 100°C for 10 hours, calcined at 240°C for 3 hours, and then calcin...

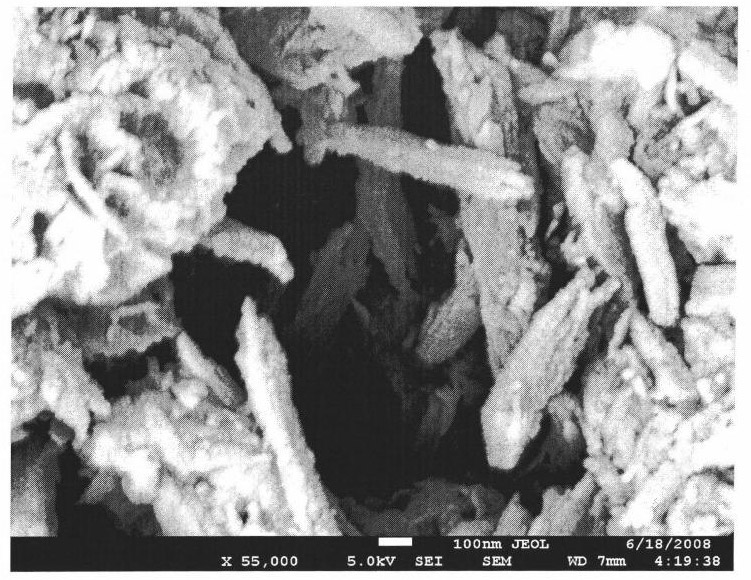

Embodiment 2

[0052]Dissolve 66g of tetraethyl orthosilicate in 85g of ethanol, add 74g of urea, heat at 75°C and mix well, slowly add 70g of second-line distillate oil at 75°C, and 12g of polyisobutenyl triethanolamine maleate into the mixture, and here Mix at temperature for 10 minutes. Dissolve 126g of titanium tetrachloride in 120ml of ethanol, then add to the micelles, and mix well. At a temperature of 120°C, the temperature and pressure were maintained, and the reaction was carried out for 6 hours. After the reaction, wash with distilled water until there is no negative ion, and centrifuge. Finally, it was dried at 100° C. for 10 hours. Nano-titanium hydroxide-silicon hydroxide gel dry powder 80g is mixed homogeneously with binding agent pseudo-boehmite 20g; 3.2g dilute nitric acid (mass concentration 17%), 15g water and 3g cosolvent ethanol are mixed homogeneously, then Molded in extruder, control pressure at 23MPa. The molded product was dried at 100°C for 10 hours, calcined at ...

Embodiment 3

[0054] 100g of silica sol and 160g of urea were heated and mixed evenly and slowly added to the mixture of 49g of second-line distillate oil and 15g of polyisobutenyl triethanolamine maleate at 90°C, and mixed at this temperature for 10 minutes. Dissolve 94.4g of titanium tetrachloride in 100ml of ethanol, then add it into the micelles, and mix well. At a temperature of 120°C, the temperature and pressure were maintained, and the reaction was carried out for 6 hours. After the reaction, wash with distilled water until there is no negative ion, and centrifuge. Finally, it was dried at 100° C. for 10 hours. Nano-titanium hydroxide-silicon hydroxide gel dry powder 80g is mixed homogeneously with binding agent pseudo-boehmite 20g; 3.2g dilute nitric acid (mass concentration 17%), 15g water and 3g cosolvent ethanol are mixed homogeneously, then Molded in extruder, control pressure at 23MPa. The molded product was dried at 100°C for 10 hours, calcined at 240°C for 3 hours, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com