Preparation method of graphene loaded with anatase type nano titanium dioxide and application thereof

A nano-titanium dioxide and anatase-type technology, applied in the field of electrochemical power supply, can solve the problems of unfavorable uniform dispersion of nano-titanium dioxide, poor stability of graphene suspension, environmental pollution, etc., and achieve low cost, easy operation, and high discharge specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 3g of natural flake graphite to 120ml of sulfuric acid with a mass concentration of 98%, and slowly add 15g of potassium permanganate while stirring the mixture at a rate of 200rpm in an ice-water bath; During the process, continue to stir for 1 hour; raise the temperature of the water bath to 65°C and stir for 2 hours, while stirring, slowly add 250ml of deionized water, add deionized water to the resulting mixture to 1400ml, then add 30ml of hydrogen peroxide with a mass concentration of 30%, and react 20min. The resulting product was centrifuged and washed with dilute hydrochloric acid with a mass concentration of 5%, until no SO 4 2- (with BaCl 2 Inspection), the obtained washings were dried in a vacuum oven at a temperature of 60° C. to obtain graphite oxide.

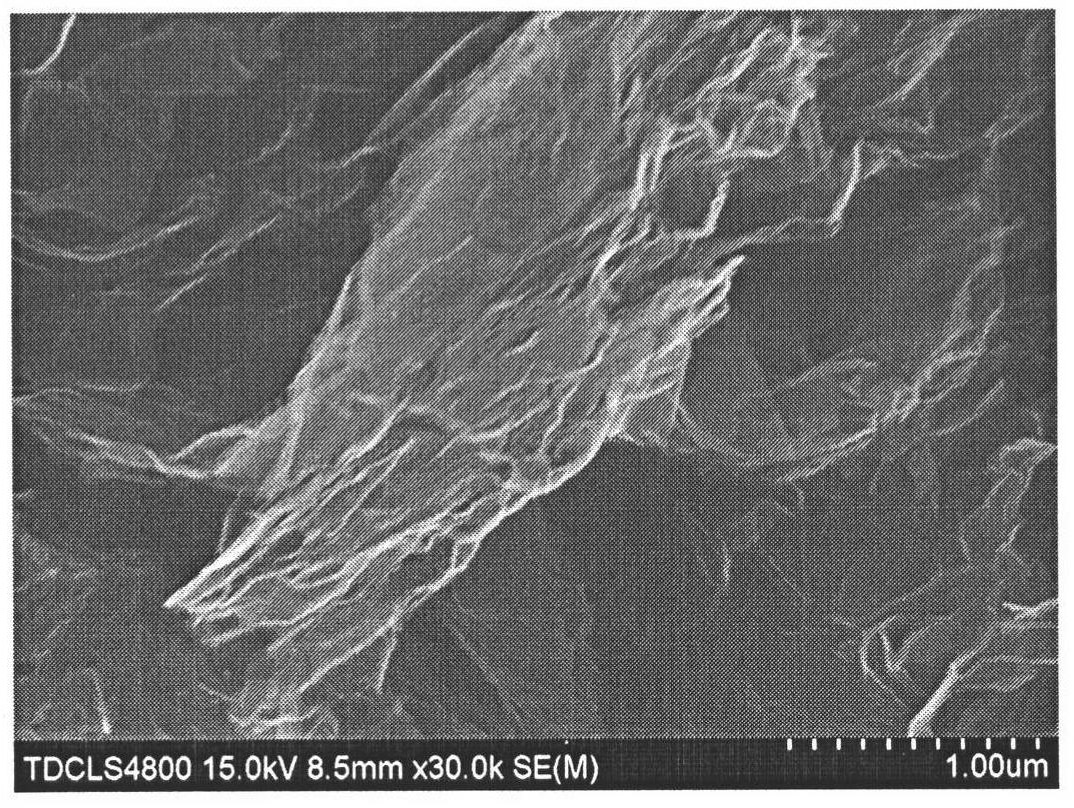

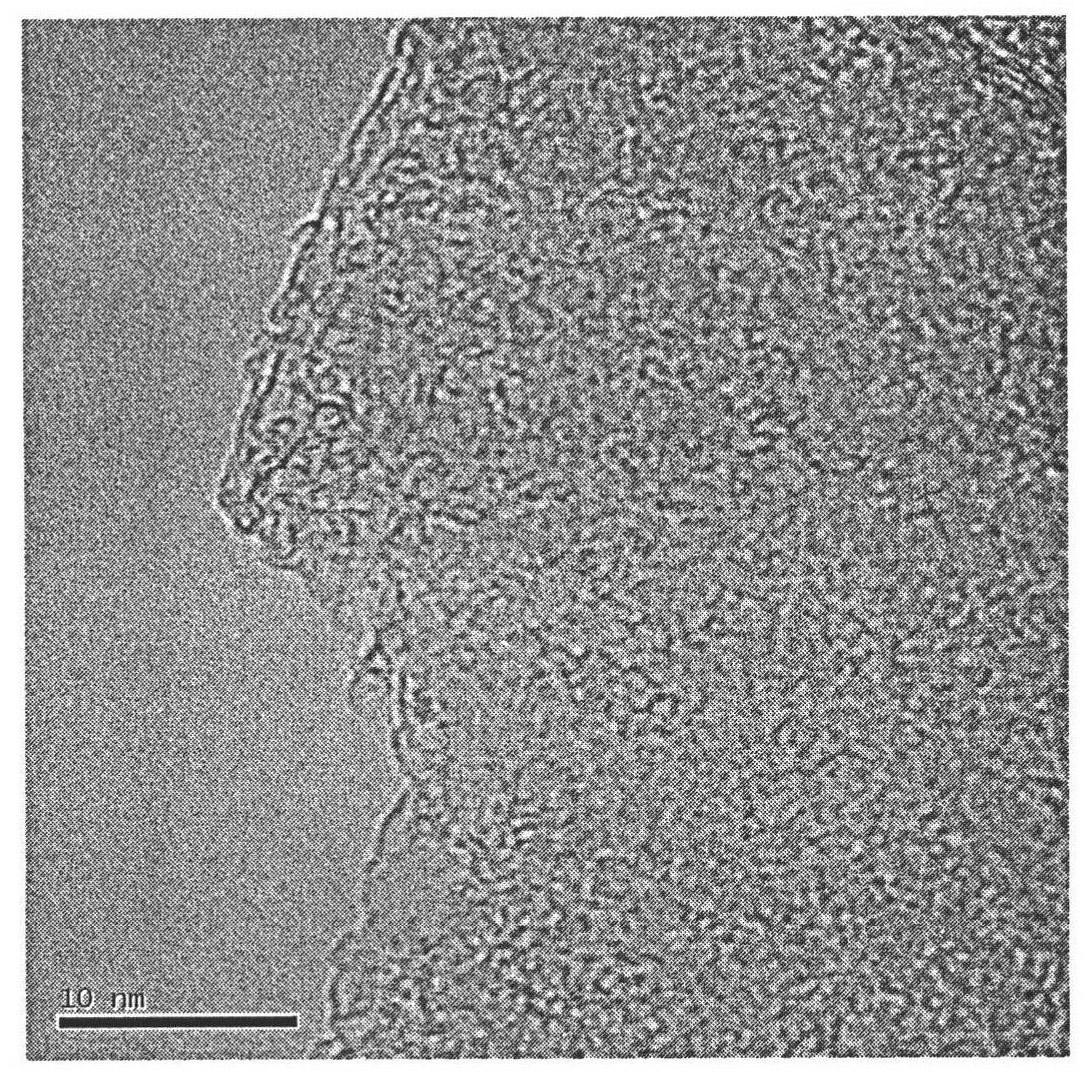

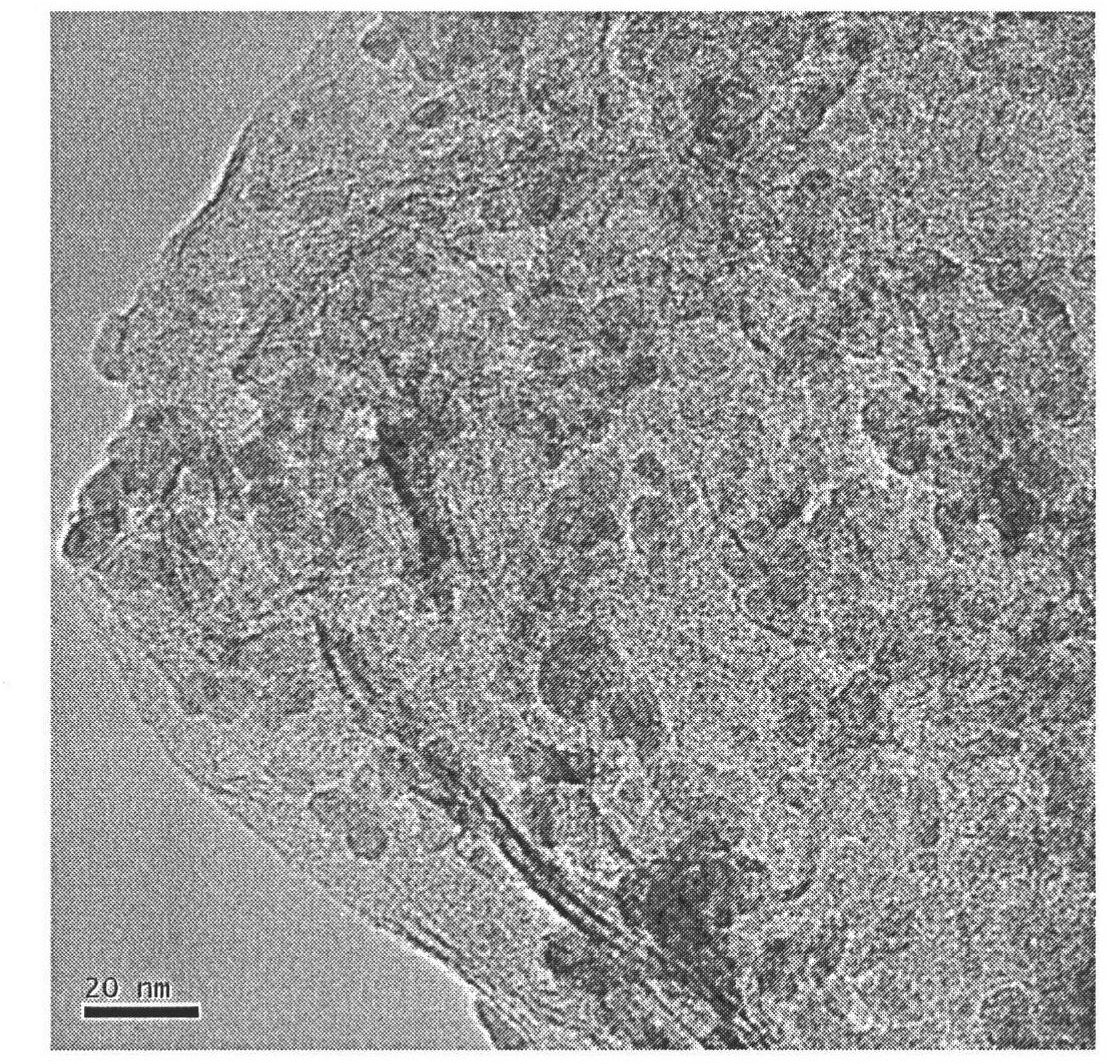

[0021] Take 100 mg of graphite oxide obtained in the above steps and disperse it in 100 ml of deionized water, and ultrasonically peel it off for 2 hours to obtain a graphene oxide solution with a con...

Embodiment 2

[0025] The process of preparing graphene loaded with anatase-type nano-titanium dioxide in this example is the same as that of Example 1, except that the calcination temperature is changed from 500°C in Example 1 to 400°C, and calcined for 2h to obtain nano Graphene supported on titania. The XRD spectrogram of the graphene supported by nano titanium dioxide made by the present embodiment is as follows Figure 4 As shown in (b), it can be seen from the figure that the crystallinity of the anatase crystal form of nano-titanium dioxide is lower than that in Example 1.

Embodiment 3

[0027] The process of preparing graphene loaded with anatase-type nano-titanium dioxide in this example is the same as that of Example 1, except that the calcination temperature is changed from 500°C in Example 1 to 300°C, and calcined for 2 hours to obtain nano Graphene supported on titania. The XRD spectrogram of the graphene supported by the nano-titanium dioxide prepared by the present embodiment is as follows Figure 4 As shown in (c), it can be seen from the figure that the crystallinity of the anatase crystal form of nano-titanium dioxide is lower than that in Example 1 and Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com