Titanium dioxide/active carbon fiber photocatalyst and its preparation method and uses in air purification

A photocatalyst and titanium hydroxide technology, applied in the field of air purification, can solve the problem of no report on the optimal process conditions, and achieve the effects of no secondary pollution, large adsorption capacity, and high efficiency secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add ammonia water to Ti(SO 4 ) 2 In the solution, adjust the pH value of the solution to 7, filter and wash the white amorphous flocculent precipitate, and beat the washed precipitate to obtain a titanium hydroxide emulsion, which is oxidized by molar ratio in the titanium hydroxide emulsion. Titanium: sulfuric acid 1:0.005, add dilute sulfuric acid solution (distilled water: sulfuric acid is 2:1 by volume ratio), stir evenly and vibrate in ultrasonic wave for 60 minutes to obtain acidified emulsion, which is sealed and stored.

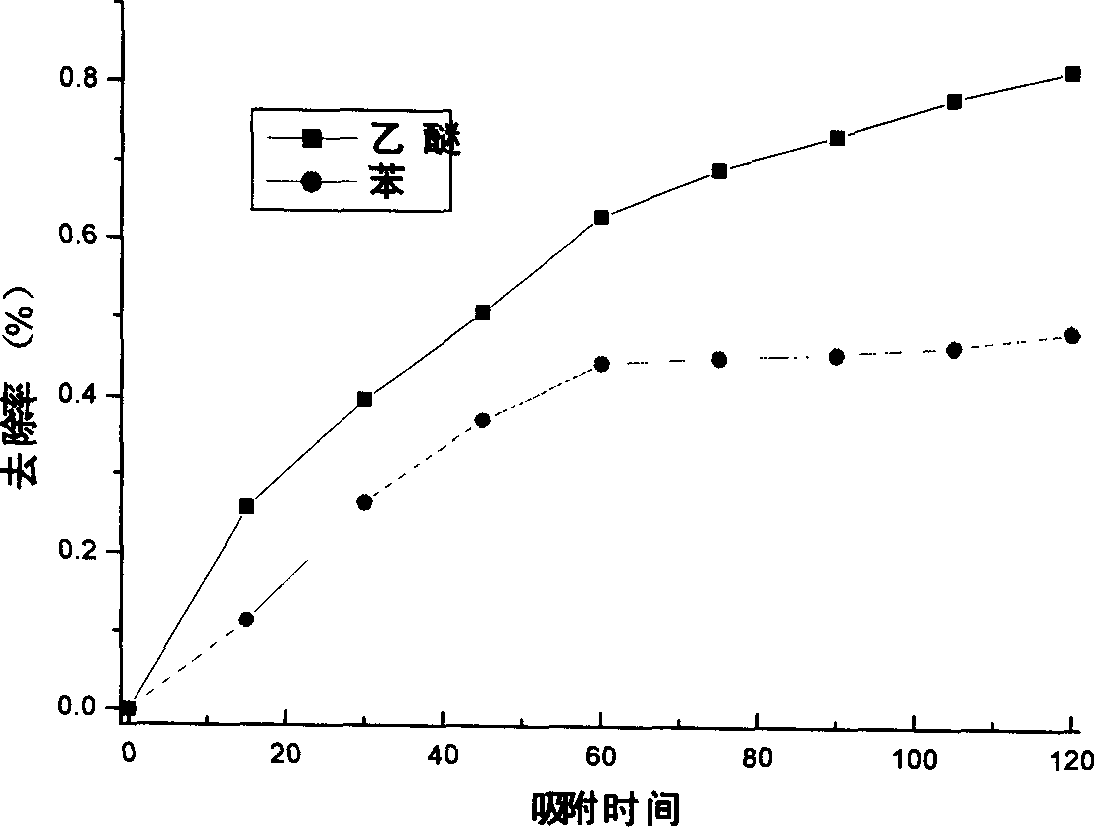

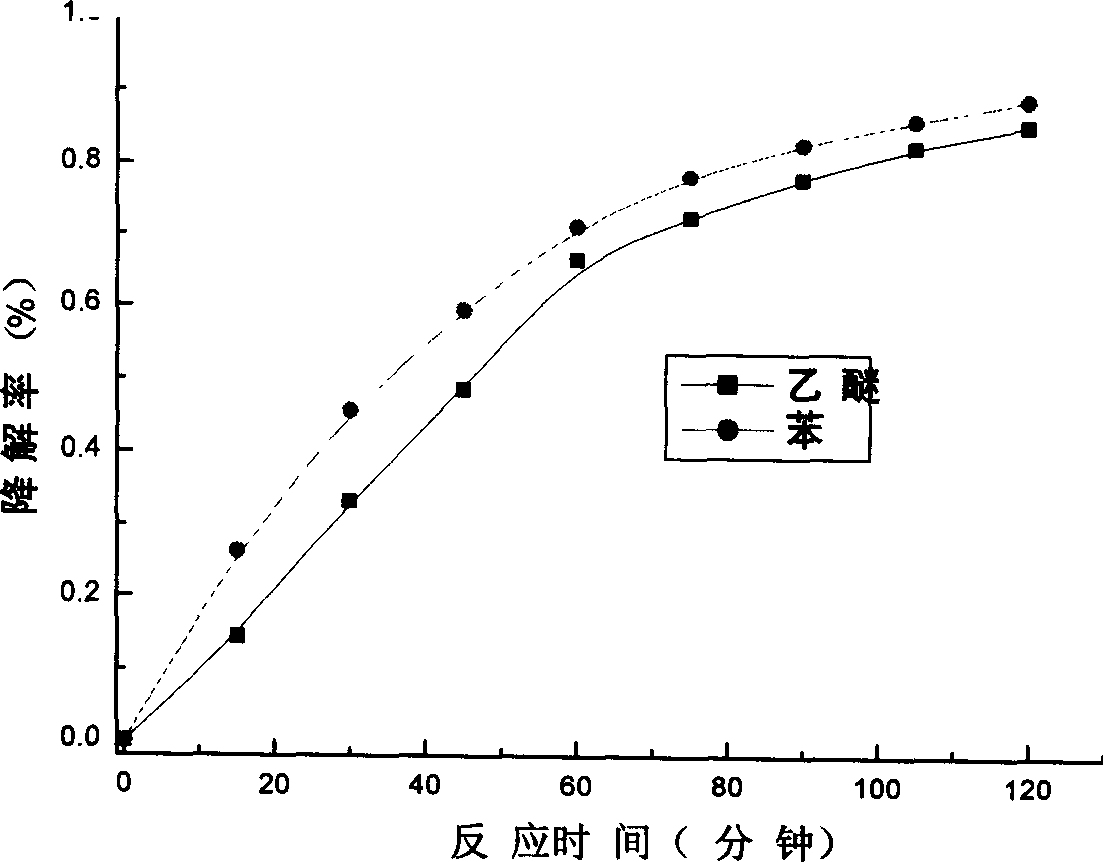

[0024] (2) Soak in distilled water and then ultrasonically wash the activated carbon fiber cloth (specific surface 1000m 2 / g, benzene adsorption saturation 35%) 2 times, after washing clean, dry at 50 ℃, immerse in the above-mentioned 10% acidified emulsion (mass volume ratio) that makes, take out after vibrating in ultrasonic wave for 60 minutes, at 50 The photocatalyst precursor loaded with one layer of titanium hydroxide can be prepar...

Embodiment 2

[0027] (1) Add ammonia water to Ti(SO 4 ) 2 In the solution, a white amorphous flocculent precipitate is formed, filtered and washed, and the washed precipitate is beaten to obtain a titanium hydroxide emulsion. In the titanium hydroxide emulsion, the molar ratio of titanium hydroxide: sulfuric acid is 1: 0.05 and dilute Sulfuric acid solution (prepared by distilled water: sulfuric acid at a volume ratio of 6: 1), stirred evenly, and then vibrated in an ultrasonic wave for 30 minutes to obtain an acidified emulsion, which was sealed and stored.

[0028] (2) Soak in distilled water and then ultrasonically wash activated carbon fiber felt (specific surface 1200m 2 / g, benzene adsorption saturation 50%) 3 times, after washing clean, dry at 80 ℃, immerse in the above-mentioned 8% acidified emulsion (mass volume ratio) that makes, take out after vibrating in ultrasonic wave for 30 minutes, at 80 The photocatalyst precursor loaded with one layer of titanium hydroxide can be prepar...

Embodiment 3

[0031] (1) Add ammonia water to Ti(SO 4 ) 2 In the solution, a white amorphous flocculent precipitate is formed, filtered and washed, and the washed precipitate is beaten to obtain a titanium hydroxide emulsion. In the titanium hydroxide emulsion, the molar ratio of titanium hydroxide: sulfuric acid is 1: 0.10 and dilute Sulfuric acid solution (prepared by volume ratio of distilled water: sulfuric acid is 10:1), stirred evenly and then vibrated in ultrasonic wave for 60 minutes to obtain acidified emulsion, sealed and preserved.

[0032] (2) Soak in distilled water and then ultrasonically wash activated carbon fiber felt (specific surface 1200m 2 / g, benzene adsorption saturation 50%) once, washed and dried at 100°C, immersed in the 5% acidified emulsion (mass volume ratio) prepared above, taken out after oscillating in ultrasonic waves for 60 minutes, at 100 The photocatalyst precursor loaded with one layer of titanium hydroxide can be prepared by drying at ℃. Repeat the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com