Method for preparing strontium titanate nanoparticles

A technology of nano-particles and strontium titanate, which is applied in the direction of nanotechnology, chemical instruments and methods, titanium compounds, etc., can solve the problems of small particles without strontium titanate materials, non-orientation aggregation, etc., and achieve low cost and easy production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

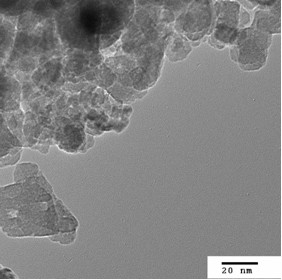

Image

Examples

example 1

[0021] 1) Dissolve tetrabutyl titanate in ethylene glycol methyl ether to adjust the Ti in the solution 4+ The ion concentration is 0.5mol / L

[0022] 2) Under stirring, add 1.5ml of ammonia solution with a mass concentration of 30% to the tetrabutyl titanate ethylene glycol methyl ether solution prepared in 1), precipitate, filter, and wash with deionized water for 6 times to obtain titanium Co-precipitation of oxyhydroxides;

[0023] 3) Dissolve strontium nitrate in deionized water to adjust the Sr in the solution 2+ The ion concentration is 1.5mol / L

[0024] 4) Potassium hydroxide is dissolved in deionized water, and the concentration of the configuration is 2mol / L potassium hydroxide aqueous solution

[0025] 5) Put 6g glucose at 180 o C hydrothermal reaction for 10h to obtain glucose hydrothermal decomposition solution

[0026] 6) Add titanium oxyhydroxide co-precipitation, strontium nitrate aqueous solution, glucose hydrothermal decomposition solution 20ml and potass...

example 2

[0029] 1) Dissolve tetrabutyl titanate in ethylene glycol methyl ether to adjust the Ti in the solution 4+ The ion concentration is 1mol / L

[0030] 2) Under stirring, add 1.5ml of ammonia solution with a mass concentration of 30% to the tetrabutyl titanate ethylene glycol methyl ether solution prepared in 1), precipitate, filter, and wash with deionized water for 6 times to obtain titanium Co-precipitation of oxyhydroxides;

[0031] 3) Dissolve strontium nitrate in deionized water to adjust the Sr in the solution 2+ The ion concentration is 2mol / L;

[0032] 4) Dissolve potassium hydroxide in deionized water, and prepare an aqueous potassium hydroxide solution with a concentration of 2 mol / L

[0033] 5) Put 6g glucose at 180 o C hydrothermal reaction for 10h to obtain glucose hydrothermal decomposition solution

[0034] 6) Add titanium oxyhydroxide co-precipitation, strontium nitrate aqueous solution, glucose hydrothermal decomposition solution 20ml and potassium hydroxide...

example 3

[0037] 1) Dissolve tetrabutyl titanate in ethylene glycol methyl ether to adjust the Ti in the solution 4+ The ion concentration is 0.6mol / L;

[0038] 2) Under stirring, add 1.5ml of ammonia solution with a mass concentration of 30% to the tetrabutyl titanate ethylene glycol methyl ether solution prepared in 1), precipitate, filter, and wash with deionized water for 6 times to obtain titanium Co-precipitation of oxyhydroxides;

[0039] 3) Dissolve strontium nitrate in deionized water to adjust the Sr in the solution 2+ The ion concentration is 2.4mol / L

[0040] 4) Dissolve potassium hydroxide in deionized water, and prepare an aqueous potassium hydroxide solution with a concentration of 2 mol / L

[0041] 5) Put 5g glucose at 160 o C hydrothermal reaction for 12h to obtain glucose hydrothermal decomposition solution

[0042] 6) Add titanium oxyhydroxide co-precipitation, strontium nitrate aqueous solution, glucose hydrothermal decomposition solution 20ml and potassium hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com