Composition for metallic surface treatment and metallic base material with surface treatment envelope

A technology of metal surface treatment and composition, applied in the direction of metal material coating process, etc., can solve the problems of poor corrosion resistance, dissolution, insufficient adhesion, etc., and achieve excellent corrosion resistance, excellent storage, and adhesion excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

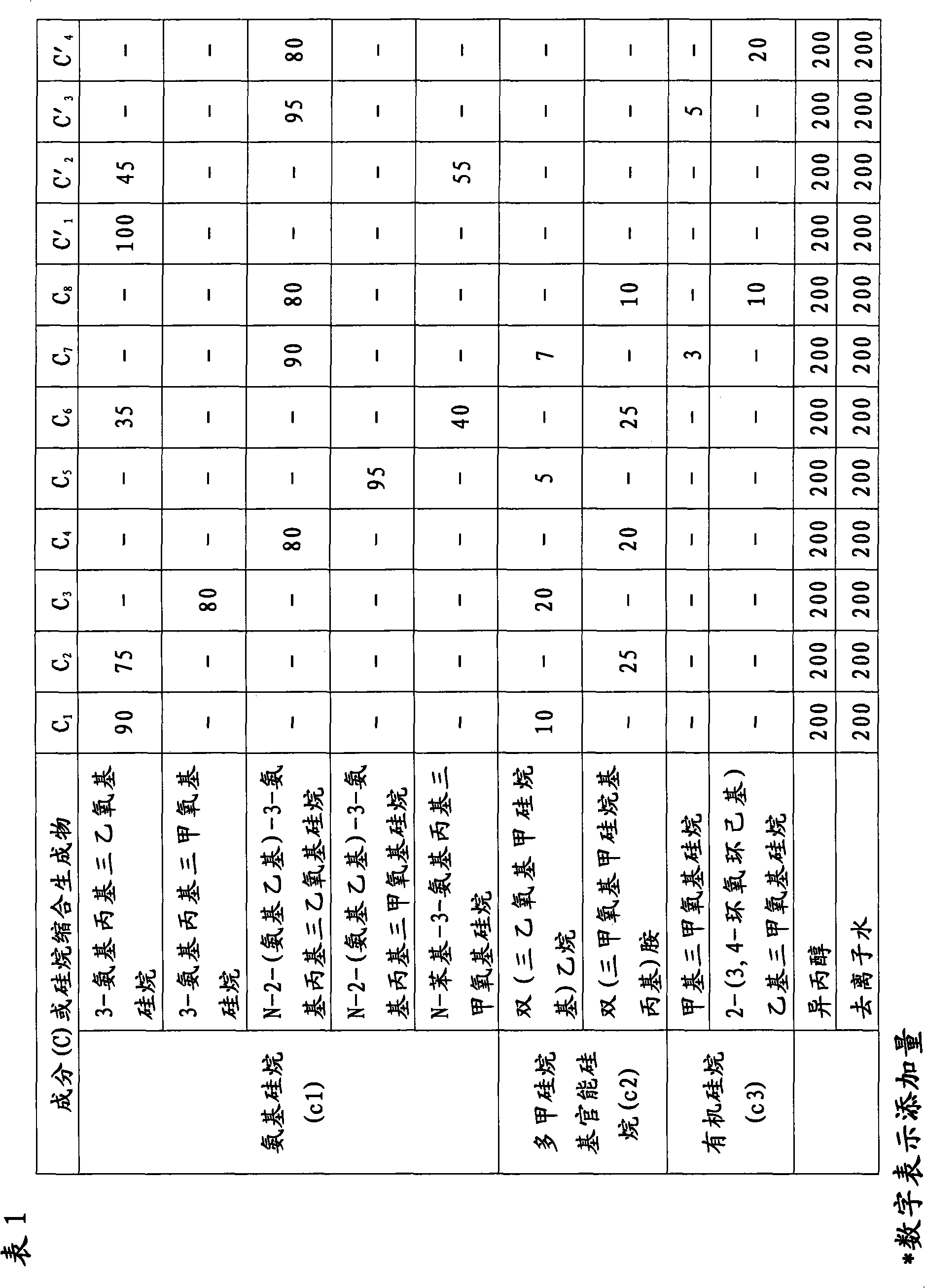

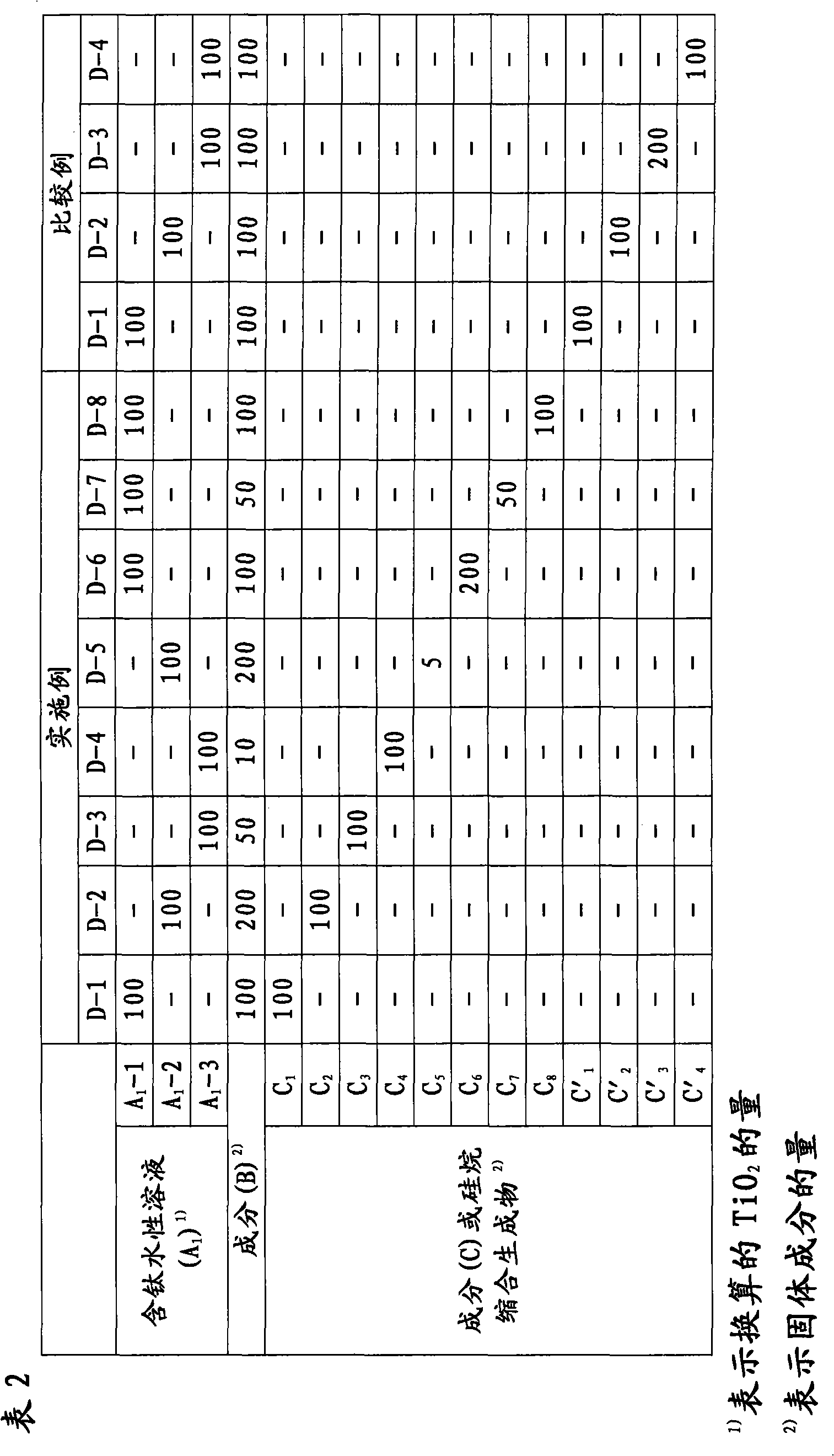

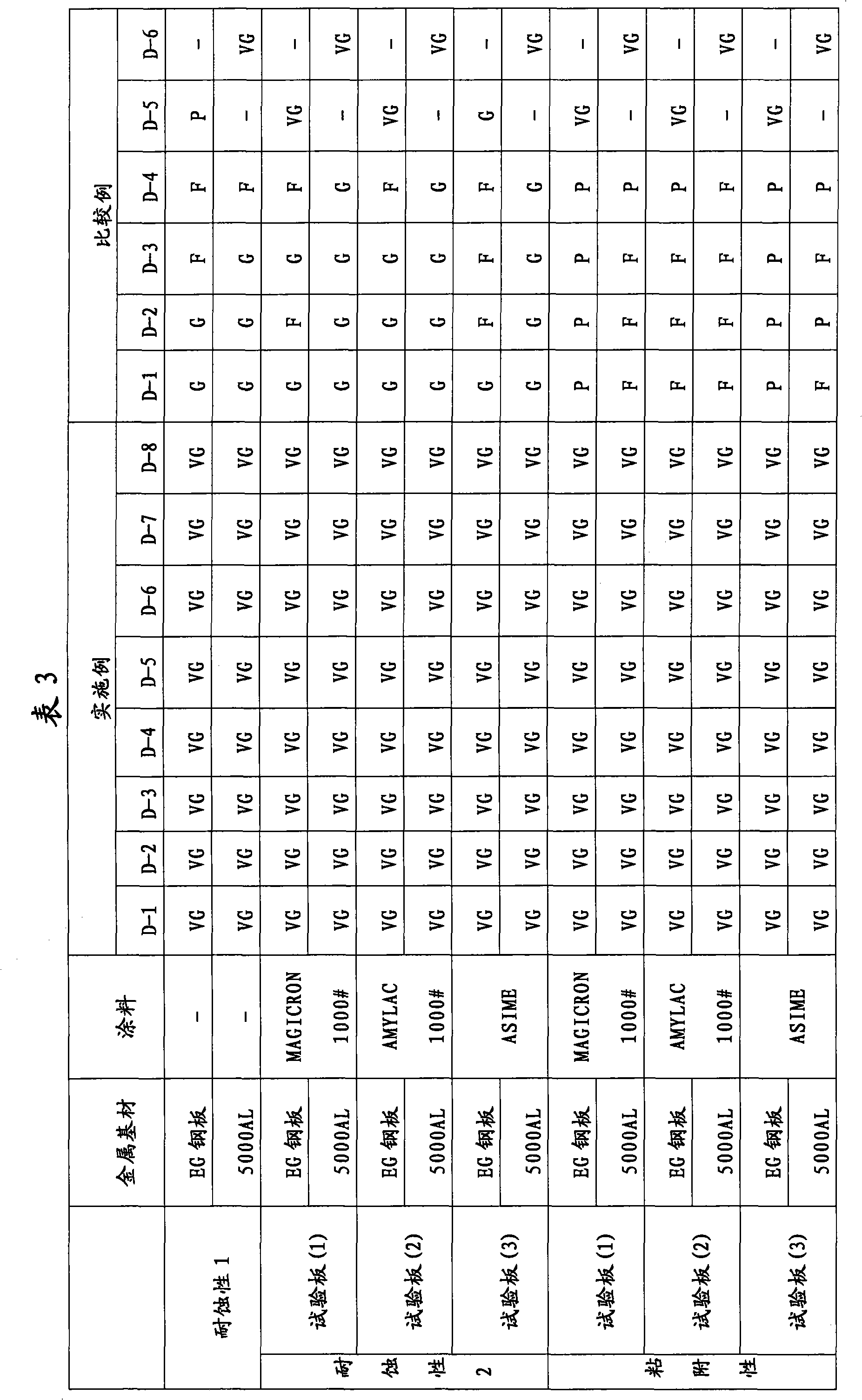

[0121] Hereinafter, the present invention will be described in more detail with reference to examples. In addition, "part" and "%" represent "part by mass" and "% by mass", respectively.

[0122]

[0123] [Titanium-containing aqueous solution (A 1 ) preparation]

preparation example D-1

[0125] In a mixture of 10 parts of 30% hydrogen peroxide water and 100 parts of deionized water, a mixture of 10 parts of titanium tetraisopropoxide and 10 parts of isopropanol was added dropwise while stirring at 20° C. for 1 hour. Then, it was aged at 25°C for 2 hours to obtain a transparent, slightly yellowish, and slightly viscous aqueous solution of peroxotitanic acid (a 1 ) Titanium-containing aqueous solution (A 1 -1). Aqueous solution containing titanium (A 1 Converted TiO in -1) 2 The concentration is 2%.

preparation example D-2

[0127] Except using an equivalent amount of tetra-n-butoxytitanium instead of tetraisopropoxytitanium, operate in the same way as Preparation Example D-1 to obtain a titanium-containing aqueous solution (A 1 -2). Aqueous solution containing titanium (A 1 Converted TiO in -2) 2 The concentration is 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com