Novel aluminum emitter junction N type single crystal silicon solar battery

A solar cell, emitter junction technology, used in photovoltaic power generation, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

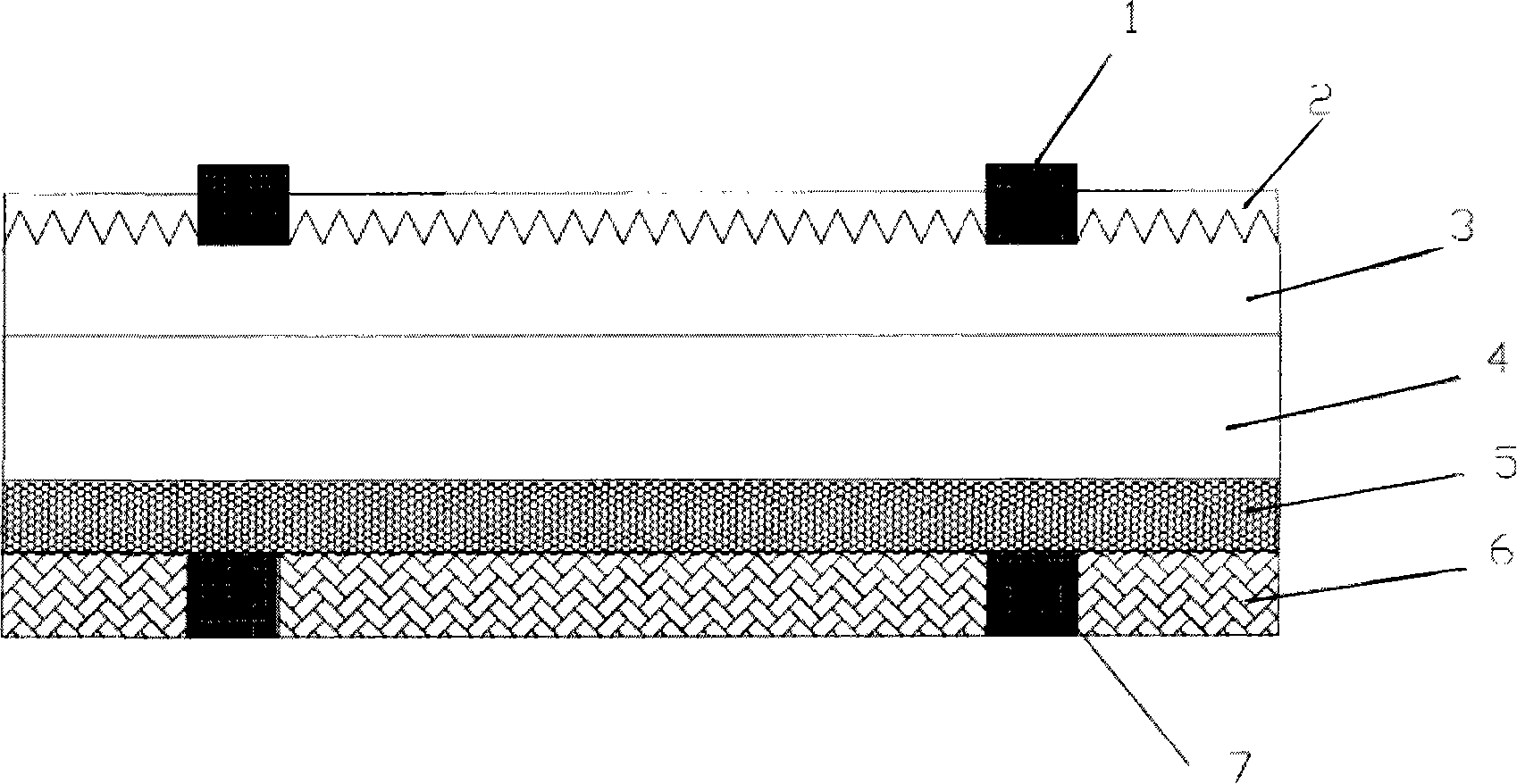

Image

Examples

Embodiment Construction

[0033] (1) The N-type monocrystalline silicon wafer with a resistivity of 0.2-15Ω.cm is subjected to chemical pre-cleaning and textured etching;

[0034] N-type monocrystalline silicon wafers with a resistivity of 0.2-15Ω.cm are placed in 0.5%-2% Na 2 SiO 3 Ultrasonic pre-cleaning in the solution for 5-10 minutes, rinse with deionized water, remove the surface damage layer with heated 20% NaOH or KOH solution, and then add a small amount of alcohol or isopropanol with 1%-2% NaOH or KOH solution The suede surface is corroded, soaked in dilute hydrochloric acid and dilute hydrofluoric acid, rinsed with deionized water, and dried.

[0035] (2) On the front side of the N-type single crystal silicon wafer, phosphorus is diffused N + Layer: N + Layer adopts conventional gas phase carrying POCl 3 Thermal diffusion, silicon wafers are placed back to back in a quartz boat during diffusion, the temperature is 850-920°C, and the sheet resistance is controlled at 20-60Ω / cm 2 .

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com