1500MPa-grade hot-formed steel with double-sided non-equal-thickness aluminum-silicon coating and resistance spot welding method for 1500MPa-grade hot-formed steel

A thermoformed steel and resistance spot welding technology, which is applied in resistance welding equipment, coatings, welding equipment, etc., can solve the problems of insufficient service life of the new aluminum-silicon coated thermoformed steel resistance spot welding electrodes, and solve the problem of weldability , Improve cold bending performance, increase the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

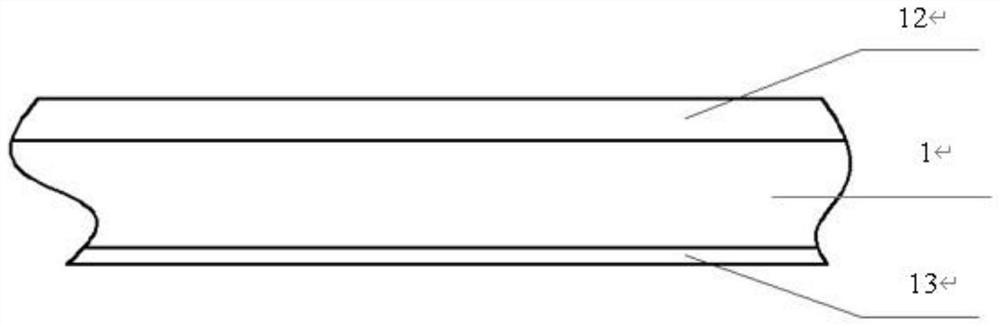

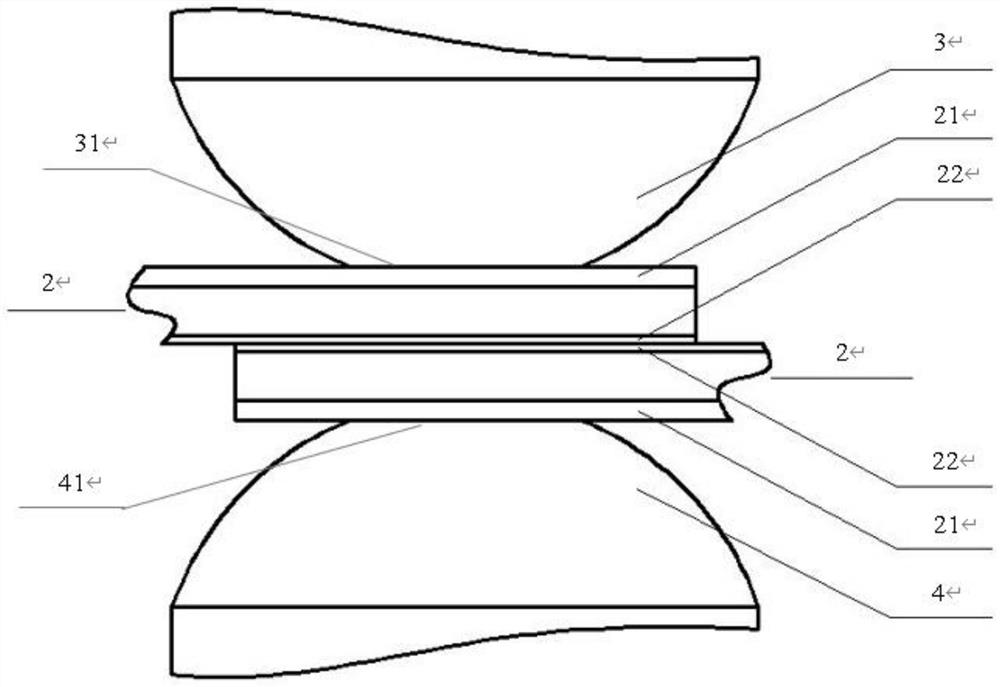

[0032] 1) Preparation of hot-formed steel products with double-sided non-equal thickness aluminum-silicon coating:

[0033] Through the control of the smelting process, the main chemical components of the hot-formed steel substrate are: C: 0.10-0.25, Si: 0.10-0.50, Mn: 0.80-1.50, P: ≤0.03, S: ≤ 0.03, Al: ≤0.10, Cr: 0.10-0.50, Mo: ≤0.03, B: 0.004-0.01, N: ≤0.01, and the balance is Fe and unavoidable impurities. Through the control of continuous casting, hot rolling, acid rolling and other processes in the production process of the automobile sheet, a base material with a thickness of 1.2 mm and the properties of the components meeting the requirements is obtained.

[0034] In the hot-dip coating process, through the control of the process, the products with the characteristics of "coating 1" and "coating 2" are respectively obtained on the surface of the substrate, and double-sided non-equal thickness aluminum-silicon coated steel sheets are obtained. The aluminum-silicon coati...

Embodiment 2

[0045] 1) Preparation of hot-formed steel products with double-sided non-equal thickness aluminum-silicon coating:

[0046] Through the control of the smelting process, the main chemical components of the hot-formed steel substrate are: C: 0.10-0.25, Si: 0.10-0.50, Mn: 0.80-1.50, P: ≤0.03, S: ≤ 0.03, Al: ≤0.10, Cr: 0.10-0.50, Mo: ≤0.03, B: 0.004-0.01, N: ≤0.01. The balance is Fe and unavoidable impurities. Through the control of continuous casting, hot rolling, acid rolling and other processes in the production process of the automobile sheet, a base material with a thickness of 1.5 mm and the properties of the components meeting the requirements is obtained.

[0047] In the hot-dip coating process, through the control of the process, products with the characteristics of "coating 1" and "coating 2" are respectively obtained on the surface of the substrate, and double-sided non-equal thickness aluminum-silicon coated steel sheets are obtained. The aluminum-silicon coating is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com