Solderable conductive silver paste with low-temperature back of crystalline silicon solar cell and preparation method

A technology of solar cells and conductive silver paste, which is applied in the manufacture of cables/conductors, circuits, and electrical components. It can solve problems such as soldering resistance to electric soldering irons, short storage time of pastes, and poor bonding strength of the substrate to achieve strong bonding strength. , prolong the storage time, the effect of small volume resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

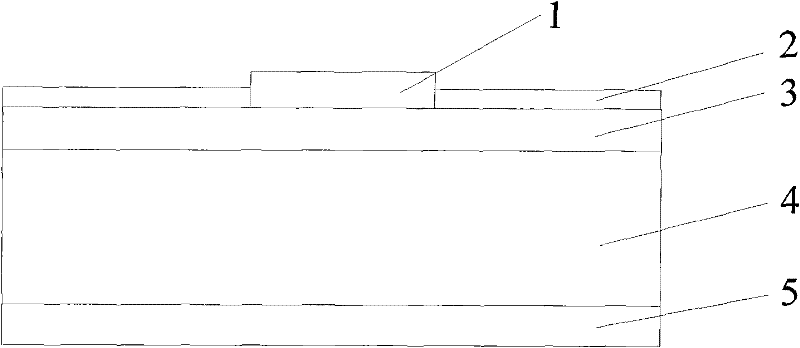

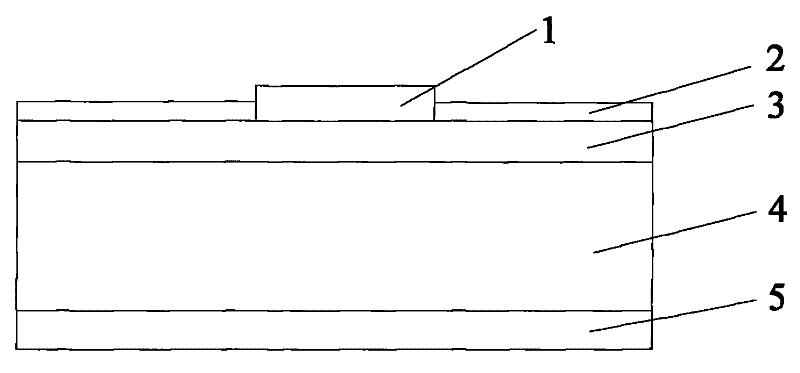

Image

Examples

Embodiment 1

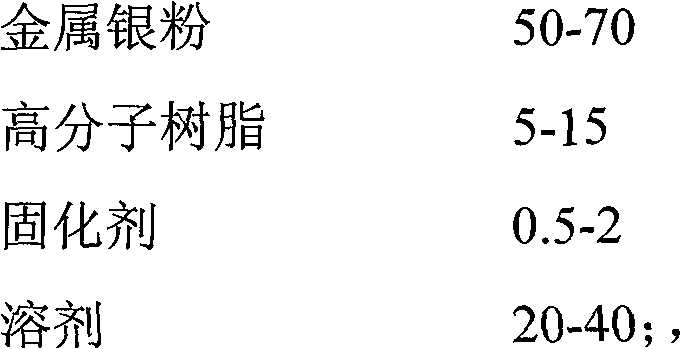

[0032] A method for preparing a low-temperature solderable conductive silver paste on the back side of a crystalline silicon solar cell, the method comprising the following steps:

[0033] (1) Prepare materials according to the following components: 60kg of metallic silver powder, 10kg of polymer resin, 1kg of curing agent, and 29kg of solvent. The particle size of the silver powder is 4μm, the tap density is 3.0g / ml, the polymer resin is a modified bisphenol A epoxy resin, the softening point is 130°C, the curing agent is a closed melamine curing agent, and the solvent is ethylene glycol Butyl ether acetate;

[0034] (2) Preparation of carrier: Weigh modified bisphenol A type epoxy resin and ethylene glycol butyl ether acetate, heat it to 80°C and keep the temperature constant until the resin dissolves at constant temperature until the viscosity is 30000-40000 centipoise, and then filtering the resin on a mesh cloth of 300-400 mesh to obtain a carrier;

[0035] (3) Preparat...

Embodiment 2

[0039] (1) Prepare materials, prepare materials according to the following components: 65kg of metallic silver powder, 8kg of polymer resin, 1kg of curing agent, and 26kg of solvent. The particle size of the silver powder is 7μm, the tap density is 3.2g / ml, the polymer resin is modified bisphenol F epoxy resin, the softening point is 140°C, the curing agent is a blocked anhydride curing agent, and the solvent is ethylene glycol Butyl ether acetate;

[0040] (2) Preparation of the carrier: Weigh the modified bisphenol F epoxy resin and ethylene glycol butyl ether acetate, heat it to 80°C and keep the temperature constant until the resin dissolves at a constant temperature until the viscosity is 20000-40000 centipoise, and then filtering the resin on a mesh cloth of 300-400 mesh to obtain a carrier;

[0041] (3) Preparation of silver paste: Weigh metal silver powder and closed anhydride curing agent, then fully mix it with the carrier in a mixer, and then use a high-speed dispe...

Embodiment 3

[0044] (1) Prepare materials, prepare materials according to the following components: 50kg of metallic silver powder, 15kg of polymer resin, 2kg of curing agent, and 20kg of solvent. The particle size of the silver powder is 7μm, the tap density is 4.0g / ml, the polymer resin is a modified bisphenol F epoxy resin, the softening point is 140°C, the curing agent is a closed imidazole curing agent, and the solvent is ethylene glycol Butyl ether acetate;

[0045] (2) Preparation of the carrier: Weigh the modified bisphenol F epoxy resin and ethylene glycol butyl ether acetate, heat it to 80°C and keep the temperature constant until the resin is dissolved at constant temperature until the viscosity is 20000 centipoise, and then the resin Filter and remove impurities on a 300-mesh mesh cloth to obtain a carrier;

[0046] (3) Preparation of silver paste: Weigh metal silver powder and closed imidazole curing agent, then fully mix it with the carrier in a mixer, and then use a high-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com