Dual welding spots inductor in high frequency packaged by ceramics and its production method

A ceramic packaging and inductor technology, applied in the manufacture of inductors/transformers/magnets, transformer/inductor housings, inductors with magnetic cores, etc. Poor reliability and other problems, to achieve the effect of large inductance value, small size, and reducing the short circuit of the winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

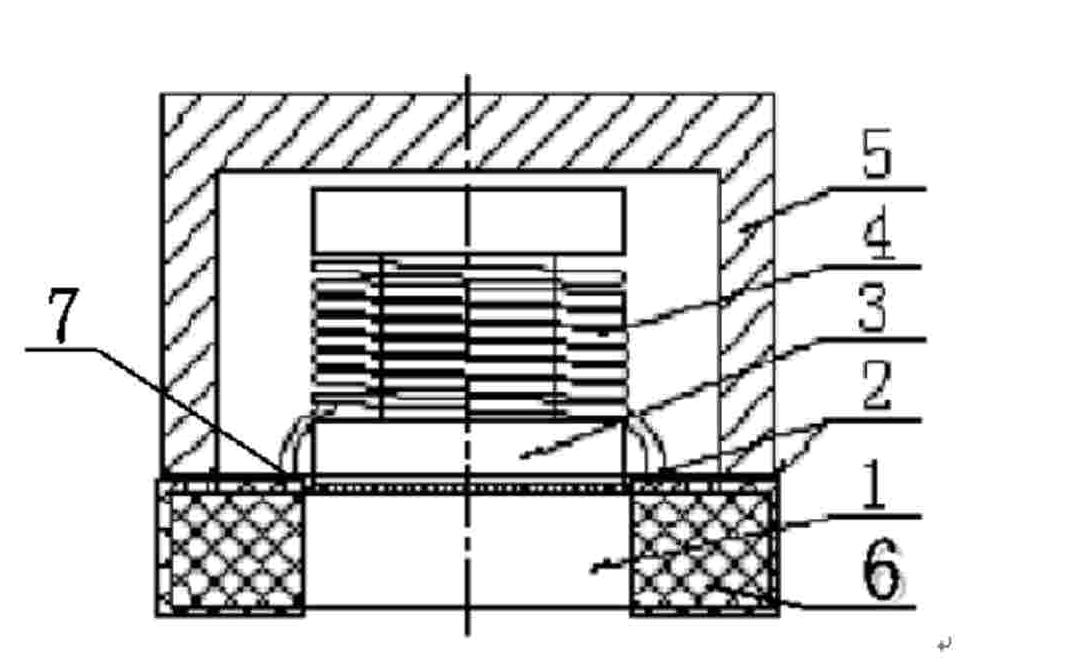

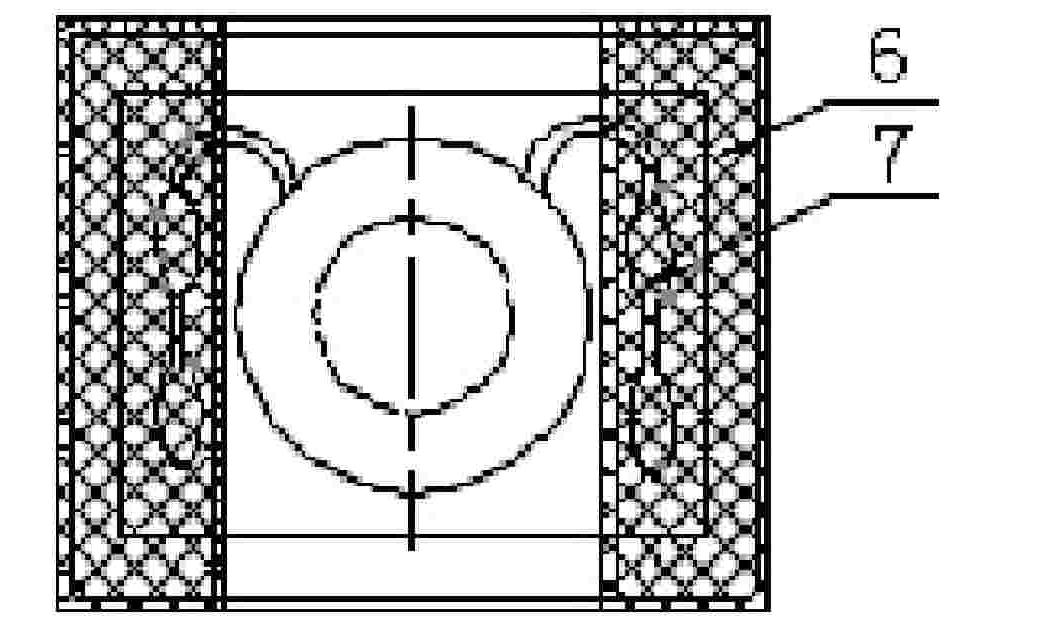

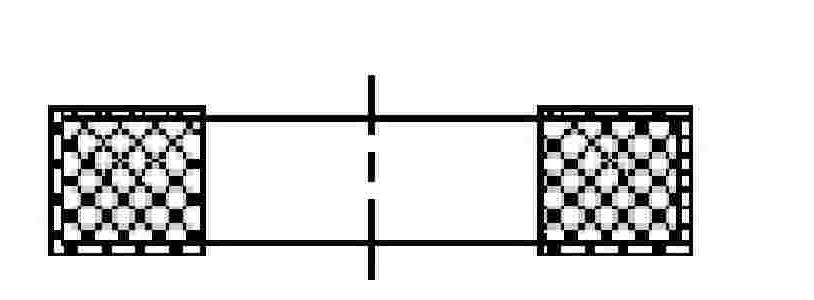

[0026] Embodiments of the invention: as figure 1 with 2 As shown, at first the magnetic core 3 is fixed on the ceramic substrate 1 with the metal lead-out end with an adhesive 2, and all surfaces at both ends of the ceramic substrate 1 are electroplated to form a metal coating 6, preferably gold-plated or tin-plated, so The ceramic substrate 1 becomes a simple but very practical conduction structure. Double-layer enameled wire 4 is used to wind on the magnetic core 3, and then the leading end is welded on the metal coating 6 of the ceramic substrate 1 by thermocompression welding to obtain double solder joints 7 and metal coating 6, so that the double-layer enameled wire 4 can be welded The point and the derived welding surface required by the user are effectively dispersed to avoid the occurrence of solder joint damage and failure when the product is soldered on the PCB board. The ceramic shell 5 and the ceramic substrate 1 are sealed and bonded with the adhesive 2 , the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com